Filter by

Mounting Location

Current per Circuit

DIN Rail Trade Size

DIN Rail Height

Electrical Connection

Width

Length

Certification

Maximum Temperature

Mounting Hole Center-to-Center Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

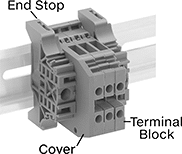

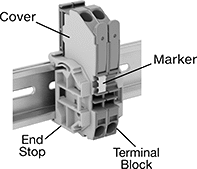

Modular DIN-Rail Mount Terminal Blocks

Terminal Blocks with Screw-Clamp Terminals

Terminal Blocks

|

Terminal Blocks | Covers | Markers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

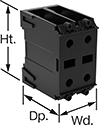

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Color | For DIN Rail Trade Size | Dia. | No. of | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—20 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 22 to 12 | Screw Terminal | No. 6 | 3/8" | 1 3/4" | 7/8" | 1/2" | 257 | Black | — | 0.17" | 4 | 0000000 | 00000 | 00000000 | 00000 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—30 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 22 to 12 | Screw Terminal | No. 6 | 7/16" | 2 1/16" | 1 1/8" | 1/2" | 257 | Black | — | 0.18" | 4 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—20 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 22 to 12 | Screw Terminal | No. 6 | 7/16" | 2 1/16" | 1 3/8" | 3/4" | 257 | Black | — | 0.18" | 4 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—30 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 to 12 | Screw Terminal | No. 8 | 9/16" | 2 11/16" | 1 5/16" | 11/16" | 257 | Black | — | 0.22" | 4 | 0000000 | 0000 | 00000000 | 0000 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—75 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 to 6 | Screw Terminal | No. 10 | 11/16" | 3 3/16" | 1 13/16" | 3/4" | 266 | Black | — | 0.22" | 4 | 00000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—200 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 to 2 | Stud Terminal | 1/4" | 13/16" | 2 9/16" | 3" | 2 7/16" | 257 | Black | 3 | 0.22" | 6 | 0000000 | 00000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Temperature Terminal Blocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Material | Color | Dia. | No. of | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—20 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 24 to 12 | Screw Terminal | M3 | 5/16" | 1" | 15/16" | 3/4" | 1,200 | Ceramic | White | — | — | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 24 to 12 | Screw Terminal | M3 | 1/2" | 1 7/16" | 15/16" | 3/4" | 1,200 | Ceramic | White | 0.14" | 2 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—30 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 22 to 10 | Screw Terminal | M4 | 9/16" | 1 5/8" | 1" | 3/4" | 1,200 | Ceramic | White | 0.14" | 2 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—65 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 18 to 6 | Screw Terminal | M4 | 11/16" | 1 7/8" | 1 1/16" | 15/16" | 1,200 | Ceramic | White | 0.14" | 2 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—20 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 20 to 12 | Screw-Clamp Terminal | No. 8 | 7/8" | 2 7/16" | 1 1/4" | 13/16" | 840 | Ceramic | Beige | 0.19" | 2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Terminal Blocks for Motors

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Color | Dia. | No. of | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—35 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 18 to 8 | Stud Terminal | M4 | 1 1/16" | 2 1/2" | 1 7/16" | 1 5/8" | 266 | Black | 0.23" | 2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—160 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 12 to 2/0 | Stud Terminal | M8 | 1 9/16" | 4 7/16" | 2 11/16" | 3" | 266 | Black | 0.35" | 2 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—315 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 8 | Stud Terminal | M12 | 2 3/4" | 7 1/16" | 6 1/2" | 4 3/16" | 266 | Black | 0.43" | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

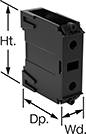

Distribution Blocks

Screw-Clamp Terminal Input Connection

Distribution Blocks | Terminal Block End Stops | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Connections Per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Current per Circuit, amp | Voltage | Input (For Wire Ga.) | Output (For Wire Ga.) | Wd. | Ht. | Dp. | Enclosure Rating | Certification | Flammability Rating | Features | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIN-Rail Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Circuits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 115 | 1,000V AC/1,000V DC | 1 (8-2) | 1 (10-6), 6 (14-6) | 3 5/16" | 3" | 2" | IP20, NEMA 1 | UL Recognized Component, CE Marked | — | — | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 600V AC/600V DC | 1 (14-2/0) | 1 (14-2/0) | 2 5/8" | 3" | 2 9/16" | — | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | Detachable Cover | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 600V AC/600V DC | 1 (14-2/0) | 4 (14-4) | 2 5/8" | 3" | 2 9/16" | — | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | Detachable Cover | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 600V AC/600V DC | 1 (14-2/0) | 4 (14-4) | 2 5/8" | 3" | 2 9/16" | — | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | Detachable Cover, Quick-Disconnect Load Connection | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 600V AC/600V DC | 1 (14-2/0) | 6 (14-4) | 2 5/8" | 3" | 2 9/16" | — | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | Detachable Cover | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 175 | 1,000V AC/1,000V DC | 1 (6-2/0) | 1 (10-6), 6 (14-6) | 3 5/16" | 3" | 2" | IP10, NEMA 1 | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | — | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Circuits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 335 | 600V AC/600V DC | 1 (14-4/0) | 6 (14-2) | 5 5/8" | 5" | 3 15/16" | — | UL Listed, C-UL Listed | — | — | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 350 | 600V AC/600V DC | 2 (14-2/0) | 6 (14-4) | 5 5/8" | 5" | 3 15/16" | — | UL Listed, C-UL Listed | — | — | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 510 | 600V AC/600V DC | 2 (6-4/0) | 8 (14-2) | 5 5/8" | 5" | 3 15/16" | — | UL Listed, C-UL Listed | — | — | 0000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stud-Terminal Input Connection

No. of Connections Per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Current per Circuit, amp | Voltage | Input (For Wire Ga.) | Output (For Wire Ga.) | Terminal Size | Wd. | Ht. | Dp. | Certification | Flammability Rating | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

DIN-Rail Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Circuits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 600V AC/600V DC | 1 (14-3/0) | 1 (14-3/0) | 1/4" | 2 5/8" | 3" | 2 9/16" | UL Recognized Component, CSA Certified, CE Marked | UL 94 V-0 | Detachable Cover | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Surface Mount | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3 Circuits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 310 | 600V AC/600V DC | 1 (14-4/0) | 1 (14-4/0) | 3/8" | 5 3/8" | 4" | 3 1/2" | UL Recognized Component, CSA Certified | UL 94 V-0 | Detachable Cover | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Touch-Safe Terminal Blocks

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Color | Dia. | No. of | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—20 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 | 22 to 12 | Screw-Clamp Terminal | M3 | 5/16" | 7/8" | 3/4" | 3/4" | 221 | White | 0.12" | 2 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—30 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 | 18 to 10 | Screw-Clamp Terminal | M3 | 3/8" | 1 1/16" | 3/4" | 13/16" | 221 | White | 0.15" | 2 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—40 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 | 20 to 8 | Screw-Clamp Terminal | M3 | 1/2" | 1 1/4" | 15/16" | 7/8" | 221 | White | 0.17" | 2 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—63 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 | 14 to 6 | Screw-Clamp Terminal | M3 | 9/16" | 1 9/16" | 1 1/8" | 1 1/16" | 221 | White | 0.17" | 2 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—85 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3 | 18 to 4 | Screw Terminal | 1/4" | 5/8" | 1 3/4" | 1 1/4" | 1 1/8" | 302 | Black | 0.18" | 2 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Connect Terminal Blocks

Terminal Blocks | DIN Rail Mounting Adapters | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Mounting Holes | Black | White | ||||||||||||||||

No. of Circuits | No. of Terminals per Circuit | For Wire Ga. | Wire Connection | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | For DIN Rail Trade Size | Dia. | No. of | Each | Each | Each | ||||

| 3 | 4 | 20 to 12 | Spring-Clamp Terminal | 1/2" | 1 7/16" | 7/8" | 1 3/8" | 221 | 3 | 0.13" | 2 | 0000000 | 00000 | 0000000 | 00000 | 000000 | 00000 | |

Quick-Connect Modular DIN-Rail Mount Terminal Blocks

Terminal Blocks with Spring-Clamp Terminals

Terminal Blocks | Covers | End Stops | Adjacent Jumpers | Alternate Jumpers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No. of Circuits | No. of Terminals per Circuit | For Wire Ga. | Wd., mm | Ht., mm | For DIN Rail Trade Size | Choose a Color | 1-24 | 25-Up | Each | Each | Insulation | Each | Insulation | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC/300V DC—15 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 2 | 28 to 12 | 5 | 103 | 3 | Blue , Gray | 00000000 | 000000 | 000000 | 00000000 | 00000 | 00000000 | 00000 | Insulated | 00000000 | 00000 | Insulated | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Through-Panel Terminal Blocks

For Panel Cutout | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Lg. | Ht. | Max. Temp., ° F | Color | Dia. | No. of | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—60 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 10 to 3 | Screw-Clamp Terminal | M5 | 5/8" | 3" | 1 13/16" | 1 3/16" | 2" | 1" | 194 | Black | 0.21" | 2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Space-Saving Circuit Board Terminal Blocks

Pin | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Lg. | Material | Max. Temp., ° F | Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

300V AC—15 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 22 to 12 | Screw-Clamp Terminal | M3 | 3/16" | 5/8" | 3/8" | 9/16" | 0.12" | Tin-Plated Nickel | 220 | Black | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Terminal Blocks for RTD and Thermocouple Connection Heads

Mounting Slots | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Max. Wire Ga. | Wire Connection | Dia. | Ht. | Wd. | Dp. | For Thermocouple Wire Type | For RTD Probe Resistance, ohm | Max. Temp., ° F | Material | Ht. | Wd. | No. of | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oblong | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 | Screw Terminal | — | 1 3/8" | 2" | 1" | J, JX, K, KK, KX, T, TX | 100; 1,000 | 1,000 | Ceramic | 3/16" | 9/16" | 2 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 | Screw Terminal | 1 15/16" | — | — | 3/4" | J, JX, K, KK, KX, T, TX | 100; 1,000 | 1,000 | Ceramic | 3/16" | 5/16" | 2 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||