Filter by

Wire Connection

System of Measurement

Electrical Connection

Current per Circuit

Material

Mounting Hole Center-to-Center Length

Terminal Material

Maximum Temperature

DFARS Specialty Metals

Export Control Classification Number (ECCN)

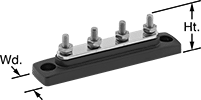

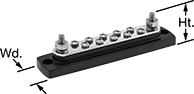

Harsh-Environment High-Current Distribution Bars

|  |  |

Stud Terminals 1 Circuit | Stud and Screw Terminals 1 Circuit | Stud and Screw Terminals 2 Circuits |

Distribution Bars | Distribution Bar Covers | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stud Terminals | Screw Terminals | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

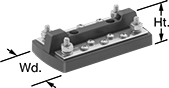

Voltage | Current | No. per Circuit | Size | No. per Circuit | Size | Lg. | Wd. | Ht. | Mounting Fasteners Included | Dia. | No. of | Certification | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stud Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 100 amp 100 amp | 4 | No. 10 | — | — | 4 3/16" | 7/8" | 1 1/8" | No | 0.21" | 2 | CE Marked | 0000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 130 amp 150 amp | 4 | 1/4" | — | — | 5 7/8" | 1 1/4" | 1 1/2" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 250 amp 250 amp | 4 | 5/16" | — | — | 5 7/8" | 1 1/2" | 1 11/16" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 250 amp 250 amp | 6 | 5/16" | — | — | 7 3/4" | 1 1/2" | 1 11/16" | No | 0.21" | 2 | CE Marked | 000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stud and Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 100 amp 100 amp | 2 | No. 10 | 5 | No. 8 | 4 3/16" | 7/8" | 1 1/8" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 130 amp 150 amp | 2 | 1/4" | 10 | No. 8 | 5 7/8" | 1 1/4" | 1 1/2" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 130 amp 150 amp | 2 | 1/4" | 20 | No. 8 | 9 1/8" | 1 1/4" | 1 1/2" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 250 amp 250 amp | 2 | 5/16" | 6 | No. 10 | 5 7/8" | 1 1/2" | 1 11/16" | No | 0.21" | 2 | CE Marked | 000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 250 amp 250 amp | 2 | 5/16" | 12 | No. 10 | 7 3/4" | 1 1/2" | 1 11/16" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 545 amp 600 amp | 4 | 3/8" | 4 | No. 8 | 7" | 2" | 2" | No | 0.26" | 4 | CE Marked | 000000 | 000000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 545 amp 600 amp | 8 | 3/8" | 4 | No. 8 | 11 3/8" | 2" | 2" | No | 0.39" | 4 | CE Marked | 000000 | 000000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

2 Circuits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 300V AC 48V DC | 130 amp 150 amp | 2 | 1/4" | 5 | No. 10 | 4 7/8" | 2 9/16" | 1 1/4" | No | 0.21" | 2 | CE Marked | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Distribution Posts

Terminal Blocks for Motors

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Color | Dia. | No. of | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—35 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 18 to 8 | Stud Terminal | M4 | 1 1/16" | 2 1/2" | 1 7/16" | 1 5/8" | 266 | Black | 0.23" | 2 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—160 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 12 to 2/0 | Stud Terminal | M8 | 1 9/16" | 4 7/16" | 2 11/16" | 3" | 266 | Black | 0.35" | 2 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1,000V AC/1,000V DC—315 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 8 | Stud Terminal | M12 | 2 3/4" | 7 1/16" | 6 1/2" | 4 3/16" | 266 | Black | 0.43" | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Terminal Blocks

|

Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Circuits | For Wire Ga. | Wire Connection | Terminal Size | Terminal Ctr.-to-Ctr. | Lg. | Wd. | Ht. | Max. Temp., ° F | Color | For DIN Rail Trade Size | Dia. | No. of | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

600V AC/600V DC—200 amp per Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 14 to 2 | Stud Terminal | 1/4" | 13/16" | 1 7/8" | 3" | 2 7/16" | 257 | Black | 3 | 0.22" | 4 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 14 to 2 | Stud Terminal | 1/4" | 13/16" | 2 9/16" | 3" | 2 7/16" | 257 | Black | 3 | 0.22" | 6 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

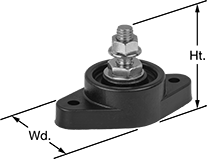

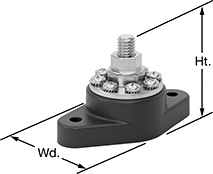

High-Current Distribution Posts

Stud Terminals | Screw Terminals | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. Per Circuit | Size | No. Per Circuit | Size | Current, amp | Voltage, V DC | Lg. | Wd. | Ht. | Mounting Fasteners Included | Dia. | No. of | Certification | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stud and Screw Terminals | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1 Circuit | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 1/4" | 8 | No. 8 | 150 | 48 | 3 5/16" | 1 3/4" | 2 3/16" | No | 1/4" | 2 | CE Marked | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 3/8" | 8 | No. 8 | 150 | 48 | 3 5/16" | 1 3/4" | 2" | No | 1/4" | 2 | CE Marked | 000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||