How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

Pressure Test Fittings

Check pressure without permanently installing a gauge. Fittings have an NPT male connection for installation in your pipe or tank. Wrench-tighten the fitting onto your equipment, then insert the gauge adapter (sold separately) into the fitting. Connect gauge adapters to gauges with 1/4 pipe size NPT male threads.

Plugs | Gauge Adapters | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Thread Pitch, mm | Max. Pressure, psi | Gasket Material | Ht. | For Use With | Each | Each | ||

NPT Male × UNF Male | ||||||||||

Brass | ||||||||||

| 1/8 | 3/8"-24 | __ | 1,000 | EPDM Rubber | 7/16" | Air, Water | 0000000 | 00000 | 0000000 | 000000 |

| 1/4 | 3/8"-24 | __ | 1,000 | EPDM Rubber | 7/16" | Air, Water | 0000000 | 0000 | 0000000 | 00000 |

NPT Male × Metric Male | ||||||||||

Steel | ||||||||||

| 1/8 | M16 | 2 | 5,800 | Fluoroelastomer Rubber | 1 1/2" | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Water | 0000000 | 00000 | 0000000 | 00000 |

| 1/4 | M16 | 2 | 5,800 | Fluoroelastomer Rubber | 1 1/2" | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Water | 0000000 | 00000 | 0000000 | 00000 |

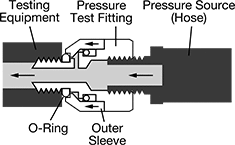

Quick-Install Pressure Test Fittings

Thread these fittings onto your testing equipment by hand for a secure connection in testing applications—no tools, tape, or sealant required. Use them with gauges and other equipment as a temporary connection. When pressure is applied, the O-ring on the outlet presses against the testing equipment, creating a tight seal.

| Pipe Size | Max. Pressure, psi | Temperature Range, °F | Gasket Material | For Use With | Each | |

NPT Male Inlet Plug | ||||||

|---|---|---|---|---|---|---|

416 Stainless Steel | ||||||

| 1/8 | 5,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 0000000 |

| 1/4 | 5,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 000000 |

| 3/8 | 4,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 000000 |

| 1/2 | 4,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 000000 |

| 3/4 | 4,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 000000 |

| 1 | 4,000 | -65° to 212° | Polyurethane Rubber | Air, Argon, Diesel Fuel, Fuel Oil, Gasoline, Hydraulic Fluid, Hydraulic Fluid (Petroleum Based), Natural Gas, Nitrogen, Oxygen, Water | 0000000 | 000000 |

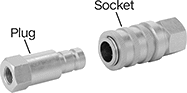

Quick-Disconnect Hose Couplings for Pressure Testing

Add quick connection points for mechanical gauges and other diagnostic equipment to your line. These couplings are also known as test ports and diagnostic couplings. To take a reading, connect a socket to your gauge using a hose assembly. Then push the socket into a plug that’s permanently threaded into a test port on your line. No threading or unthreading is necessary. Add additional plugs to your line to take measurements at different points. To quickly move the gauge to a different test port, pull back the sleeve on the socket to disengage.

A complete coupling consists of a plug and socket (both sold separately). The plug and socket both have a shut-off valve to stop flow when the coupling is separated, so they're sometimes called double shut-off couplings. They meet ISO 15171-1, which is an international standard for dimensional and performance standards of flat-face diagnostic push-to-connect couplings.

Note: To ensure a correct fit, make sure that the plug and socket have the same coupling size. Pressure ratings are given for static (constant) pressure conditions.

- Maximum Pressure: 6,000 psi @ 72° F

- Maximum Vacuum: 27.4 in. of Hg @ 72° F

- Temperature Range: -40° to 250° F

- Compatible With: Parker PD-Series, Eaton/Aeroquip FD90, Faster DF

- Specifications Met: ISO 15171-1, SAE J1502

Plugs are also known as nipples.

- Maximum Pressure: 6,000 psi @ 72° F

- Maximum Vacuum: 27.4 in. of Hg @ 72° F

- Temperature Range: -40° to 250° F

- Compatible With: Parker PD-Series, Eaton/Aeroquip FD90, Faster DF

- Specifications Met: ISO 15171-1, SAE J1502

Plugs are also known as nipples.

- Maximum Pressure: 6,000 psi @ 72° F

- Maximum Vacuum: 27.4 in. of Hg @ 72° F

- Temperature Range: -40° to 250° F

- Compatible With: Parker PD-Series, Eaton/Aeroquip FD90, Faster DF

- Specifications Met: ISO 15171-1, SAE J1502

Plugs are also known as nipples.

UN/UNF (SAE Straight) male threads have a gasket to prevent leaks. They’re also known as O-ring boss threads.

Sanitary Sampling Stainless Steel Tube Fittings

- For Use With: Dairy, Beverage, Water, Air, Food

- Tubing: Use with welded 316/316L stainless steel

- Specifications Met: 3-A Certified 63-03

Take samples in sanitary environments—these tube fittings won’t contaminate your lines or force you to pause them. Made of 316L stainless steel, they’ll stand up to harsh cleaners and sanitizers without corroding. They also have polished internal surfaces, minimizing the space where bacteria could grow. With quick-clamp connections, they are easy to take apart for cleaning or reconfiguring your line. All are 3-A certified to meet sanitary design standards, so they’re often used in food and beverage, pharmaceutical, and biotech applications.

All fittings require pierceable lids (sold separately) to draw samples through a hypodermic needle. Each lid is good for seven samples, and each sample leaves a hole mark, so you know when it’s time to unscrew the nut on the tube fitting and swap in a new lid. To help prevent dust and moisture from accumulating on the lid, all tube fittings have a dust cover. These lids are FDA compliant, so they keep contaminants from entering your line and also are approved for direct contact with food if they break off and fall in. Manufactured free of contaminants and allergens, all are BPA-, latex-, and phthalate-free. They’re also TSE/BSE compliant, meaning they’ve never come into contact with any animal products.

Pair these tube fittings with liquid samplers for a sample. They use gravity to draw out liquid through the needle directly into the bag.

Bag | Needle | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Capacity, ml | Ht. | Wd. | Thick., mil | Gauge | Lg. | ID | OD | Material | Connection Type | Color | Specifications Met | Each | |

PVC Plastic | |||||||||||||

| 250 | 8" | 5" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 00000 |

| 2,000 | 14" | 7" | 14 | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | ISO 10993, USP Class VI | 0000000 | 0000 |