About Selecting Temperature Sensors

More

Bolt-On Thermocouple Probes for Surfaces

Take temperature readings in high-vibration environments. These probes bolt onto motors, machines, and other equipment, so they won’t shake loose. Pick the thermocouple type that best covers the temperature range you expect your surface to be. You should also make sure the thermocouple type you choose is compatible with the device you plan to connect it to. They’re often used with temperature controllers, thermometers, and other temperature-reading devices.

These thermocouples are manufactured to conform to ASTM E230 for accuracy. Accuracy is how far off the reported value is from the actual temperature.

Probes with wire leads offer more flexibility than probes with connectors already attached because you can either wire them to a terminal block or add your own connector. For installation, note that the red wire is negative.

Probe | Cable | Wire Lead | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bolt Hole Dia. | Lg. | Wd. | Thick. | Response Time, sec. | Max. Temp., °F | Accuracy | Sensor Type | Washer Material | Lg., ft. | Material | Max. Temp., °F | Lg. | Gauge | Fasteners Included | Each | |

Type J | ||||||||||||||||

Flat-Pin Mini Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 000000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Round-Pin Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Wire Leads | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 3/8" | 5/8" | 5/16" | 1/16" | 2 | 900° | ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

Type K | ||||||||||||||||

Flat-Pin Mini Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Round-Pin Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Wire Leads | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 3/8" | 5/8" | 5/16" | 1/16" | 2 | 900° | Not Rated below 32° F ±4° F between 32° to 533° F ±0.75% above 533° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

Type T | ||||||||||||||||

Flat-Pin Mini Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Round-Pin Thermocouple Connector | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | __ | __ | No | 0000000 | 00000 |

Wire Leads | ||||||||||||||||

| 3/16" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 1/4" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

| 3/8" | 5/8" | 5/16" | 1/16" | 2 | 700° | Not Rated below 32° F ±1.8° F between 32° to 240° F ±0.75% above 240° F | Grounded | Nickel | 4 | Stainless Steel | 900° | 2 1/2" | 24 | No | 0000000 | 00000 |

Bolt-On RTD Probes for Surfaces

For reliable temperature readings in high-vibration environments, these RTD probes bolt onto the surface of motors and other equipment.

Style A and B probes are rated IP67 for protection from dust and temporary submersion.

Probes that meet DIN EN 60751 adhere to industry standards for accuracy. Probes that meet MS202 (Method 204, Test Condition D) have been tested for use in vibration-heavy environments.

Probe | Cable | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Environmental Rating | Specifications Met | Each | |

Stainless Steel Probe | ||||||||||||||

| A | 100 ohms | -40° to 190° | 1/2" | 2" | 7/16" | 5/16" | ±0.5% | 15 | 6 | Polyurethane Rubber | IP67 | DIN EN 60751 Class A | 0000000 | 0000000 |

Probe | Cable | Wire Lead | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Environmental Rating | Specifications Met | Each | |

Stainless Steel Probe | |||||||||||||||||

| B | 100 ohms | -40° to 190° | 1/4" | 1 13/16" | 7/16" | 5/16" | ±0.5% | 39 | 6 | Polyurethane Rubber | 1" | 22 | 4 | IP67 | DIN EN 60751 Class A | 0000000 | 000000 |

Probe | Cable | Wire Lead | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | RTD Type | Temp. Range, °F | Bolt Hole Dia. | Lg. | Wd. | Thick. | Accuracy | Response Time, sec. | Lg., ft. | Material | Lg. | Gauge | No. of Wires | Specifications Met | Fasteners Included | Each | |

303 Stainless Steel Probe | |||||||||||||||||

| C | 100 ohms | -55° to 500° | 5/32" | 3/8" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 0000000 |

| C | 1,000 ohms | -55° to 500° | 5/32" | 3/8" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 24 | 2 | MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

316/316L Stainless Steel Probe | |||||||||||||||||

| D | 100 ohms | -90° to 930° | 5/32" | 1 1/4" | 5/16" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

| D | 1,000 ohms | -90° to 930° | 5/32" | 1 1/4" | 5/16" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 2 | MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

300 Series Stainless Steel Probe | |||||||||||||||||

| E | 100 ohms | -90° to 930° | 5/32" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

| E | 1,000 ohms | -90° to 930° | 5/32" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | Mica Glass | 1/2" | 22 | 2 | MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

Nickel-Plated Copper Probe | |||||||||||||||||

| F | 100 ohms | -55° to 500° | 17/64" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 26 | 3 | DIN EN 60751 Class B; MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

| F | 1,000 ohms | -55° to 500° | 17/64" | 1" | 1/2" | 3/16" | ±0.12% | 10 | 3 | PTFE | 1/2" | 24 | 2 | MS202 (Method 204, Test Condition D) | No | 0000000 | 000000 |

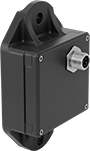

Noncontact Temperature Sensors for Tanks

Take your tank’s internal temperature with these sensors that sit on the outside walls. Since they don’t touch your tank’s contents, they won’t cause contamination or corrode. To attach the sensor to your tank, weld the included studs to your tank's walls, or stick them on your tank using adhesive. Either way you mount them, you don’t need to drill or drain your tank, saving you from scheduled downtime.

These sensors are preconfigured for stainless steel tanks with 1/8"-thick walls. They have internal sensors to record the tank’s thermal conductivity, which is used to calculate your tank's internal temperature. The information is sent through a 4-20 mA signal, so you can read the temperature on controllers and data loggers.

Use communication cords (sold separately) to calibrate these sensors on your computer when your tank isn’t the default thickness or material. Download free software and material presets to help you calibrate the sensor. If you know your tank’s thermal conductivity, you can add another material. The software also lets you monitor and log temperature.

For Tank | M12 Male Electrical Connection | Mounting Holes | Mounting Slots | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Wall Thick. | Min. Dia., ft. | Temp. Measuring Range, °F | Accuracy, °F | Response Time, sec. | Ht. | Wd. | Dp. | No. of Poles | Coding | Housing Material | Mounting Fasteners Included | No. of | Dia. | No. of | Wd. | Environmental Rating | Each | ||

4-20 mA Output Signal | |||||||||||||||||||

| 1/8" | 2 | -4° to 212° | ±0.9° | 5 | 4 3/8" | 2 5/8" | 1 5/8" | 8 | A | Nylon Plastic | Yes | 1 | 5/16" | 1 | 5/16" | IP67 | Male | 0000000 | 0000000 |

| No. of Poles | USB Standard | Lg., ft. | Max. Current | Operating System Compatibility | Specifications Met | Each | |

M12 Female × USB A Male | |||||||

|---|---|---|---|---|---|---|---|

| 8 | 2.0 | 6 1/2 | 100mA | Windows 10 or Later | CE Marked | 0000000 | 000000 |