About Duct Connections

More

About Hose

More

About Duct Hose

More

Abrasion-Resistant Very Flexible Duct Hose for Dust

- Very Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Clear or Black

- Temperature Range: -40° to 200° F

A blend of rubber and plastic creates a hose that's flexible, yet tough enough to handle abrasive particles such as grinding dust and sawdust.

Clear hose lets you see what's running through your line. It has a smooth interior for unrestricted flow.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Clear Polyurethane | |||||||||||||

| 1" | 1 3/16" | 1" | 50% | 28 in. of Hg @ 72° F | 15 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 1 1/4" | 1 7/16" | 1 1/2" | 50% | 28 in. of Hg @ 72° F | 13 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 1 1/2" | 1 11/16" | 1 1/2" | 50% | 26 in. of Hg @ 72° F | 10 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 2" | 2 1/8" | 2" | 50% | 22 in. of Hg @ 72° F | 8 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 2 1/2" | 2 5/8" | 2 1/2" | 50% | 20 in. of Hg @ 72° F | 7 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 3" | 3 3/16" | 3" | 50% | 16 in. of Hg @ 72° F | 6 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 3 1/2" | 3 7/8" | 3" | 55% | 14 in. of Hg @ 72° F | 6 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 00000000 | 0000 | 0000 |

| 4" | 4 3/16" | 4" | 50% | 12 in. of Hg @ 72° F | 5 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 00000 | 0000 |

| 5" | 5 3/16" | 5" | 50% | 10 in. of Hg @ 72° F | 5 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 6" | 6 3/16" | 6" | 50% | 7 in. of Hg @ 72° F | 4 psi @ 72° F | 0.02" | Smooth | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

Black Polyurethane | |||||||||||||

| 2" | 2 3/8" | 2" | 35% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.015" | Ribbed | Right Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 2 1/2" | 2 7/8" | 2 1/2" | 25% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 0000 | 0000 |

| 3" | 3 3/8" | 3 1/2" | 25% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 0000 | 0000 |

| 4" | 4 3/8" | 4" | 25% | 24 in. of Hg @ 72° F | 22 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 0000 |

| 5" | 5 3/8" | 4 1/2" | 25% | 13 in. of Hg @ 72° F | 18 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 6" | 6 3/8" | 5 1/2" | 25% | 8 in. of Hg @ 72° F | 15 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 7" | 7 3/8" | 6" | 20% | 8 in. of Hg @ 72° F | 10 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 8" | 8 3/8" | 6 1/2" | 20% | 2 in. of Hg @ 72° F | 7 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 10" | 10 3/8" | 7 1/2" | 20% | 2 in. of Hg @ 72° F | 7 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 12" | 12 3/8" | 9" | 20% | 1.7 in. of Hg @ 72° F | 6 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 14" | 14 3/8" | 12" | 20% | 1.1 in. of Hg @ 72° F | 5 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 16" | 16 3/8" | 14" | 20% | 0.7 in. of Hg @ 72° F | 5 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 18" | 18 3/8" | 16" | 20% | 0.5 in. of Hg @ 72° F | 4 psi @ 72° F | 0.02" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

Crush-Resistant Flexible Duct Hose with Wear Strip for Dust

- Flexible

- Compatible Clamps: Worm-Drive and Quick-Release Clamps

- Color: Black or White

- Temperature Range: -60° to 275° F

Surrounded by a protective plastic spiral, this hose bounces back to its original shape when stepped on and resists wear from being dragged across rough floors. Hose has a smooth interior for unrestricted flow. It is often used with lint, dust, and sawdust. It meets UL 94 HB for flame retardance.

Hose that is FDA compliant can be used with dry food, such as flour and sugar.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Black TPR Rubber | ||||||||||||||

| 3/4" | 13/16" | 1 1/2" | 75% | 29 in. of Hg @ 72° F | 38 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 00000 | 00000 |

| 1" | 1 3/8" | 2 1/2" | 75% | 29 in. of Hg @ 72° F | 34 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 1/4" | 1 11/16" | 2 1/2" | 75% | 29 in. of Hg @ 72° F | 28 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 75% | 29 in. of Hg @ 72° F | 23 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 3/4" | 2 3/16" | 3" | 75% | 29 in. of Hg @ 72° F | 18 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 2" | 2 1/2" | 3 1/2" | 75% | 29 in. of Hg @ 72° F | 17 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 2 1/2" | 3 1/16" | 4" | 75% | 24 in. of Hg @ 72° F | 16 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 3" | 3 9/16" | 5" | 75% | 19 in. of Hg @ 72° F | 14 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 4" | 4 5/8" | 7" | 75% | 16 in. of Hg @ 72° F | 11 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | UL 94 HB | 50 | 0000000 | 00000 | 00000 |

| 6" | 6 11/16" | 7 1/2" | 50% | 10 in. of Hg @ 72° F | 14 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | UL 94 HB | 25 | 0000000 | 00000 | 00000 |

| 8" | 8 7/8" | 9" | 50% | 6 in. of Hg @ 72° F | 14 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | UL 94 HB | 25 | 0000000 | 00000 | 00000 |

| 10" | 10 7/8" | 12" | 50% | 3 in. of Hg @ 72° F | 10 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | UL 94 HB | 25 | 0000000 | 00000 | 00000 |

White TPR Rubber | ||||||||||||||

| 1" | 1 3/8" | 2 1/2" | 75% | 29 in. of Hg @ 72° F | 34 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 1/4" | 1 11/16" | 2 1/2" | 75% | 29 in. of Hg @ 72° F | 28 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 75% | 29 in. of Hg @ 72° F | 23 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 1 3/4" | 2 3/16" | 3" | 75% | 29 in. of Hg @ 72° F | 18 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 2" | 2 1/2" | 3 1/2" | 75% | 29 in. of Hg @ 72° F | 17 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 2 1/2" | 3 1/16" | 4" | 75% | 24 in. of Hg @ 72° F | 16 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 3" | 3 9/16" | 5" | 75% | 19 in. of Hg @ 72° F | 14 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 0000 | 0000 |

| 4" | 4 5/8" | 7" | 75% | 16 in. of Hg @ 72° F | 11 psi @ 72° F | 0.026" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 50 | 0000000 | 00000 | 00000 |

| 6" | 6 11/16" | 7 1/2" | 50% | 10 in. of Hg @ 72° F | 14 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 25 | 0000000 | 00000 | 00000 |

| 8" | 8 7/8" | 9" | 50% | 6 in. of Hg @ 72° F | 14 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 25 | 0000000 | 00000 | 00000 |

| 10" | 10 7/8" | 12" | 50% | 3 in. of Hg @ 72° F | 10 psi @ 72° F | 0.045" | Smooth | Left Hand | Plastic | FDA Compliant 21 CFR 177.2600, UL 94 HB | 25 | 0000000 | 00000 | 00000 |

Antistatic Duct Hose for Dry Food

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Clear

- Temperature Range: -20° to 200° F

Blow grain, sugar, flour, and powders through this hose—it's made of FDA listed materials. Hose has a metal spiral that dissipates static when used in a grounded system. The walls are clear so you can monitor flow.

Spiral | Per Ft. | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Specifications Met | Surface Resistivity | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

Polyurethane | |||||||||||||||

| 2" | 2 5/16" | 2 1/2" | 50% | 29 in. of Hg @ 72° F | 13 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 000000 | 000000 |

| 2 1/2" | 2 3/4" | 3" | 50% | 29 in. of Hg @ 72° F | 13 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 3" | 3 5/16" | 3 1/2" | 50% | 29 in. of Hg @ 72° F | 12 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 4" | 4 5/16" | 4 1/2" | 50% | 20 in. of Hg @ 72° F | 10 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 5" | 5 5/16" | 5 1/2" | 50% | 15 in. of Hg @ 72° F | 10 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 6" | 6 5/16" | 6 1/2" | 50% | 13 in. of Hg @ 72° F | 9 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 8" | 8 3/8" | 9" | 50% | 10 in. of Hg @ 72° F | 7 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 10" | 10 3/8" | 11 1/2" | 50% | 7 in. of Hg @ 72° F | 5 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

| 12" | 12 3/8" | 13 1/2" | 50% | 6 in. of Hg @ 72° F | 5 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | FDA Compliant 21 CFR 177.2600 | 2 × 1010 ohms/sq. | 50 | 000000 | 00000 | 00000 |

Puncture- and Abrasion-Resistant Duct Hose for Metal Chips and Shavings

- Flexible

- Compatible Clamps: Worm-Drive Clamps

- Color: Clear or Black

- Temperature Range: -65° to 200° F

Blow jagged, abrasive materials through this hose without worrying about punctures or tears. It's made of extra-thick polyurethane.

Clear hose lets you monitor flow.

Warning: Hose should not be used for applications that generate a static charge.

Spiral | Per Ft. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Max. Continuous Lg., ft. | 1-24 | 25-Up | |

Clear Polyurethane | |||||||||||||

| 2" | 2 5/16" | 2 1/2" | 50% | 29 in. of Hg @ 72° F | 33 psi @ 72° F | 0.035" | Ribbed | Right Hand | Metal | 25 | 0000000 | 000000 | 000000 |

| 2" | 2 5/16" | 3" | 75% | 29 in. of Hg @ 72° F | 35 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 3" | 3 5/16" | 5" | 75% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 3" | 3 3/8" | 3 1/2" | 50% | 29 in. of Hg @ 72° F | 27 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 4" | 4 3/8" | 4 1/2" | 50% | 28 in. of Hg @ 72° F | 18 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 4" | 4 7/16" | 4" | 70% | 29 in. of Hg @ 72° F | 35 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 5" | 5 3/8" | 5 1/2" | 50% | 26 in. of Hg @ 72° F | 16 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 5" | 5 7/16" | 5" | 70% | 26 in. of Hg @ 72° F | 31 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 6" | 6 3/8" | 6 1/2" | 50% | 23 in. of Hg @ 72° F | 14 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 6" | 6 7/16" | 6" | 70% | 23 in. of Hg @ 72° F | 27 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 7" | 7 7/16" | 7 1/2" | 50% | 18 in. of Hg @ 72° F | 12 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 7" | 7 1/2" | 7" | 70% | 18 in. of Hg @ 72° F | 26 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 8" | 8 7/16" | 9" | 50% | 13 in. of Hg @ 72° F | 11 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 8" | 8 1/2" | 8" | 70% | 13 in. of Hg @ 72° F | 25 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 10" | 10 7/16" | 11 1/2" | 50% | 6 in. of Hg @ 72° F | 9 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 10" | 10 1/2" | 10" | 70% | 6 in. of Hg @ 72° F | 22 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 12" | 12 7/16" | 13 1/2" | 50% | 5 in. of Hg @ 72° F | 7 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 12" | 12 1/2" | 12" | 70% | 5 in. of Hg @ 72° F | 19 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 14" | 14 9/16" | 15 1/2" | 50% | 3 in. of Hg @ 72° F | 4 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 14" | 14 11/16" | 12" | 70% | 4 in. of Hg @ 72° F | 16 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 16" | 16 5/8" | 18" | 50% | 3 in. of Hg @ 72° F | 2 psi @ 72° F | 0.035" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 16" | 16 11/16" | 12" | 70% | 3 in. of Hg @ 72° F | 13 psi @ 72° F | 0.06" | Ribbed | Left Hand | Metal | 25 | 0000000 | 00000 | 00000 |

Black Polyurethane | |||||||||||||

| 2" | 2 5/16" | 2" | 30% | 29 in. of Hg @ 72° F | 30 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 3" | 3 5/16" | 3" | 30% | 29 in. of Hg @ 72° F | 29 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 4" | 4 3/8" | 4" | 30% | 29 in. of Hg @ 72° F | 25 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 4" | 4 1/2" | 4" | 50% | 29 in. of Hg @ 72° F | 34 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 5" | 5 5/16" | 5" | 30% | 17 in. of Hg @ 72° F | 22 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 5" | 5 1/2" | 5" | 50% | 17 in. of Hg @ 72° F | 33 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 6" | 6 7/16" | 6" | 30% | 15 in. of Hg @ 72° F | 19 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 6" | 6 1/2" | 6" | 50% | 15 in. of Hg @ 72° F | 32 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 7" | 7 7/16" | 7" | 30% | 12 in. of Hg @ 72° F | 16 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 7" | 7 9/16" | 7" | 50% | 12 in. of Hg @ 72° F | 22 psi @ 72° F | 0.045" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 8" | 8 7/16" | 8" | 30% | 9 in. of Hg @ 72° F | 14 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 8" | 8 9/16" | 8" | 50% | 9 in. of Hg @ 72° F | 29 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 10" | 10 1/2" | 8" | 30% | 4 in. of Hg @ 72° F | 11 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 10" | 10 9/16" | 10" | 50% | 4 in. of Hg @ 72° F | 25 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 12" | 12 1/2" | 10" | 30% | 2.2 in. of Hg @ 72° F | 10 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 00000000 | 00000 | 00000 |

| 12" | 12 9/16" | 12" | 50% | 2.5 in. of Hg @ 72° F | 20 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 14" | 14 9/16" | 12" | 30% | 3.3 in. of Hg @ 72° F | 8 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 14" | 14 5/8" | 14" | 50% | 3.5 in. of Hg @ 72° F | 18 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 16" | 16 9/16" | 14" | 30% | 2.2 in. of Hg @ 72° F | 7 psi @ 72° F | 0.03" | Ribbed | Right Hand | Metal | 25 | 0000000 | 00000 | 00000 |

| 16" | 16 5/8" | 16" | 50% | 2.5 in. of Hg @ 72° F | 15 psi @ 72° F | 0.06" | Ribbed | Right Hand | Metal | 25 | 0000000 | 000000 | 000000 |

Duct Hose with Wear Strip for Wood Chips and Plastic Pellets

- Flexible

- Color: Clear; Wear Strip is Off-White

- Temperature Range: -20° to 180° F

Not only is polyurethane tough enough to handle heavy particles and cardboard fibers, the material is clear so you can monitor flow. Hose has a wear strip that protects against damage and a copper wire that dissipates static buildup when used in a grounded system.

Spiral | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Compresses To | Max. Vacuum | Max. Pressure | Material Thick. | Interior Surface Texture | Direction | Material | Surface Resistivity, ohms/sq. | Max. Continuous Lg., ft. | Per Ft. | |

Per Foot | |||||||||||||

Polyurethane | |||||||||||||

| 1 1/4" | 1 11/16" | 3 1/2" | 70% | 29 in. of Hg @ 72° F | 29 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 0000000 | 00000 |

| 1 1/2" | 1 15/16" | 4" | 70% | 29 in. of Hg @ 72° F | 27 psi @ 72° F | 0.026" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 0000000 | 0000 |

| 1 3/4" | 2 3/16" | 4 1/2" | 70% | 28 in. of Hg @ 72° F | 27 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 0000000 | 0000 |

| 2" | 2 1/2" | 4 1/2" | 70% | 27 in. of Hg @ 72° F | 25 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 0000000 | 0000 |

| 2 1/2" | 3" | 5 1/2" | 70% | 24 in. of Hg @ 72° F | 23 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 0000000 | 00000 |

| 3" | 3 5/8" | 6" | 70% | 20 in. of Hg @ 72° F | 19 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 0000000 | 00000 |

| 4" | 4 5/8" | 7" | 60% | 15 in. of Hg @ 72° F | 9 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 0000000 | 00000 |

| Each | |||||||||||||

Full Coil | |||||||||||||

Polyurethane | |||||||||||||

| 1 1/4" | 1 11/16" | 3 1/2" | 70% | 29 in. of Hg @ 72° F | 29 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 00000000 | 000000 |

| 1 1/2" | 1 15/16" | 4" | 70% | 29 in. of Hg @ 72° F | 27 psi @ 72° F | 0.026" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 00000000 | 000000 |

| 1 3/4" | 2 3/16" | 4 1/2" | 70% | 28 in. of Hg @ 72° F | 27 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 00000000 | 000000 |

| 2" | 2 1/2" | 4 1/2" | 70% | 27 in. of Hg @ 72° F | 25 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 00000000 | 000000 |

| 2 1/2" | 3" | 5 1/2" | 70% | 24 in. of Hg @ 72° F | 23 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 50 | 0000000 | 000000 |

| 3" | 3 5/8" | 6" | 70% | 20 in. of Hg @ 72° F | 19 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 00000000 | 000000 |

| 4" | 4 5/8" | 7" | 60% | 15 in. of Hg @ 72° F | 9 psi @ 72° F | 0.025" | Ribbed | Left Hand | Plastic | 2 × 1010 | 25 | 00000000 | 000000 |

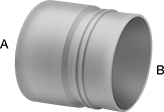

Fittings screw over the end of your duct hose so you can make connections to equipment.

Clear-View Abrasion-Resistant Dry-Food Hose

- Temperature Range: -40° to 150° F

- Material: Polyurethane Rubber with PVC Spiral

- Color: Clear with Black Spiral

- Specifications Met: FDA Compliant 21 CFR 175.105, FDA Compliant 21 CFR 177.2600

- Compatible Hose Fittings: Cam-and-Groove

Made of polyurethane, this hose lasts more than twice as long as PVC hose when moving abrasive dry food. It resists cutting and tearing almost as well as gum rubber hose. You can monitor your line since it's clear. FDA compliant, it’s safe for direct contact with food. The smooth interior prevents flour, grain, rice, sugar, and other foods from getting caught or building up inside the hose.

To keep you safe from electric shock, a static control wire runs through the spiral, creating an escape route for static buildup when used in a grounded system. The wire is embedded in the spiral, so it won’t be exposed as the hose wears. This hose is sturdy enough to be used with a suction pump to draw dry food. The spiral reinforcement on the outside increases the hose's flexibility.

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Surface Resistivity, ohms-m | Features | Max. Continuous Length, ft. | 1-19 | 20-Up | |

| 1 1/2" | 1 3/4" | 2" | 40 psi @ 72° F | 29" of Hg @ 72° F | 103 to 106 | Static Control Wire | 60 | 0000000 | 000000 | 000000 |

| 2" | 2 1/2" | 6" | 40 psi @ 72° F | 29" of Hg @ 72° F | 103 to 106 | Static Control Wire | 60 | 0000000 | 00000 | 00000 |

| 2 1/2" | 2 3/4" | 7" | 40 psi @ 72° F | 29" of Hg @ 72° F | 103 to 106 | Static Control Wire | 50 | 0000000 | 00000 | 00000 |

| 3" | 3 1/2" | 9" | 40 psi @ 72° F | 29" of Hg @ 72° F | 103 to 106 | Static Control Wire | 60 | 0000000 | 00000 | 00000 |

| 4" | 4 1/2" | 12" | 35 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | Static Control Wire | 60 | 0000000 | 00000 | 00000 |

| 5" | 5 3/4" | 14" | 35 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | Static Control Wire | 20 | 0000000 | 000000 | 00000 |

| 6" | 6 3/4" | 16" | 30 psi @ 72° F | 25" of Hg @ 72° F | 103 to 106 | Static Control Wire | 20 | 0000000 | 000000 | 000000 |

| 8" | 8 3/4" | 18" | 30 psi @ 72° F | 25" of Hg @ 72° F | 103 to 106 | Static Control Wire | 20 | 0000000 | 000000 | 000000 |

| 10" | 11" | 25" | 25 psi @ 72° F | 22" of Hg @ 72° F | 103 to 106 | Static Control Wire | 20 | 0000000 | 000000 | 000000 |

Dry-Food Hose

- Temperature Range: 0° to 150° F

- Material: PVC

- Color: Clear

- Specifications Met: See table

- Compatible Hose Fittings: Cam-and-Groove

Move flour, grain, rice, sugar, and other dry food through your line. This hose meets strict FDA standards for food safety or 3-A standards for a sanitary design. Made of PVC, it won’t impart odors or tastes on the food. A smooth interior prevents the food from getting caught or building up inside this hose. It's also clear, so you can monitor the food as it passes through the hose. This hose is sturdy enough to be used as part of vacuum system—it won’t collapse when hooked up to a vacuum pump. The spiral reinforcement on the outside increases the hose's flexibility.

Hose with a static control wire creates an escape route for static buildup when used in a grounded system. The wire runs through the spiral, so it won't be exposed as the hose wears.

Per Ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Specifications Met | Max. Continuous Lg., ft. | 1-99 | 100-Up | |

| 1" | 1 5/16" | 2" | 55 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 00000 | 00000 |

| 1 1/4" | 1 5/8" | 2" | 50 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 0000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 0000 | 0000 |

| 2" | 2 7/16" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 0000 | 0000 |

| 2 1/2" | 3" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 00000 | 00000 |

| 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 00000 | 00000 |

| 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 100 | 0000000 | 00000 | 00000 |

| 5" | 5 3/4" | 16" | 30 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 0000000 | 00000 | 00000 |

| 6" | 6 15/16" | 18" | 30 psi @ 72° F | 24" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 0000000 | 00000 | 00000 |

| 8" | 9" | 36" | 20 psi @ 72° F | 20" of Hg @ 72° F | 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 0000000 | 00000 | 00000 |

Per Ft. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Surface Resistance, ohms | Specifications Met | Max. Continuous Lg., ft. | 1-49 | 50-Up | |

| 1" | 1 5/16" | 2" | 55 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 000000 | 00000 |

| 1 1/4" | 1 11/16" | 2" | 50 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 0000 |

| 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 2" | 2 1/2" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 2 1/2" | 3 1/16" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 5" | 5 3/4" | 16" | 30 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 6" | 6 13/16" | 18" | 30 psi @ 72° F | 24" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 50 | 0000000 | 00000 | 00000 |

| 8" | 9" | 36" | 20 psi @ 72° F | 20" of Hg @ 72° F | 1010 | FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600 | 20 | 0000000 | 000000 | 00000 |

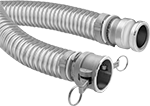

Dry-Food Hose with Cam-and-Groove Socket and Plug

- Temperature Range: 0° to 150° F

- Material: PVC

- Color: Clear

- Specifications Met: 3-A Certified 62-02, FDA Compliant 21 CFR 177.1680, FDA Compliant 21 CFR 177.2600

Transfer flour, grain, rice, sugar, and other dry food through lines connected by cam-and-groove fittings. This hose meets strict FDA standards for food safety and 3-A standards for a sanitary design. Made of PVC, it won’t impart tastes or odors on food products. Its interior is smooth, so food won't get caught or build up inside the hose. When vacuum is applied, this hose holds its shape and won't collapse. The spiral reinforcement on the outside increases its flexibility. To connect fittings, insert the plug into the socket and push the levers down.

Hose with static control wire provides an escape route for static buildup when used in a grounded system. The wire runs through the hose’s spiral, so it won’t be exposed if the hose wears.

| Coupling Size | ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 30 ft. | 50 ft. | |

Aluminum Cam-and-Groove Female Socket × Aluminum Cam-and-Groove Male Plug | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 × 1 1/2 | 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 0000000 | |||||||

| 2 × 2 | 2" | 2 7/16" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 0000000 | |||||||

| 2 1/2 × 2 1/2 | 2 1/2" | 3" | 5" | 40 psi @ 72° F | 28" of Hg @ 72° F | 0000000 | |||||||

| 3 × 3 | 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 0000000 | |||||||

| 4 × 4 | 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 0000000 | |||||||

| Coupling Size | ID | OD | Bend Radius | Max. Pressure | Max. Vacuum | Surface Resistivity, ohms-m | 5 ft. | 10 ft. | 15 ft. | 20 ft. | 25 ft. | 30 ft. | 50 ft. | |

Aluminum Cam-and-Groove Female Socket × Aluminum Cam-and-Groove Male Plug | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 1/2 × 1 1/2 | 1 1/2" | 1 15/16" | 3" | 50 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 0000000 | |||||||

| 2 × 2 | 2" | 2 1/2" | 4" | 40 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 0000000 | |||||||

| 3 × 3 | 3" | 3 11/16" | 6" | 40 psi @ 72° F | 28" of Hg @ 72° F | 103 to 106 | 0000000 | |||||||

| 4 × 4 | 4" | 4 3/4" | 10" | 35 psi @ 72° F | 24" of Hg @ 72° F | 103 to 106 | 0000000 | |||||||