About Lubricants

More

About Grease

More

Non-Bonding Heat Transfer Compounds

Also known as thermal paste, these boron-nitride compounds increase heat transfer between parts while preventing them from sticking. Unlike antiseize compounds, they don't conduct electricity, so you won't risk shorting out sensitive electronics. They're often used on thermocouple probes to improve accuracy. You can also use them in 3D printer heating blocks and other high-temperature areas to keep parts from fusing together.

Container | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Size, fl. oz. | Type | Chemical | Max. Temp. | Thermal Conductivity | Color | Includes | For Use On | Compatible With | Each | |

| 0.2 | Syringe | Boron Nitride | 1,562º F 850º C | 31.4 W/m-K @ 212° F | White | Three Applicator Brushes | 3D Printer Extruder Heating Elements, Electrical Components | Aluminum, Brass, Copper, Iron, Nickel, Stainless Steel, Steel, Titanium | 0000000 | 000000 |

| 1 | Syringe | Boron Nitride | 1,562º F 850º C | 31.4 W/m-K @ 212° F | White | __ | 3D Printer Extruder Heating Elements, Electrical Components | Aluminum, Brass, Copper, Iron, Nickel, Stainless Steel, Steel, Titanium | 0000000 | 00000 |

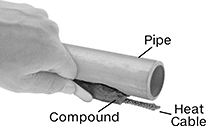

Heat-Transfer Compounds

Eliminate air gaps that cause heat loss and premature heater failure. These compounds mold around heat cable so it makes direct contact with pipes, pumps, and other parts.

Compounds with a 450° F maximum temperature don’t harden, so they maintain a tight seal even as the surface you’re heating expands and contracts. Since they’re waterproof, they also shield the surface from corrosion.

Compounds with a 750° F maximum temperature are often used with steam, hot oil, and glycol heat trace lines.

Compounds with a 1250° F or 2200° F maximum temperature are often used with steam heat trace lines, strip heaters, and ring heaters.

Container | |||||||

|---|---|---|---|---|---|---|---|

| Size | Type | Begins to Harden, hrs. | Reaches Full Strength, hrs. | For Surface Material | For Use Outdoors | Each | |

450° F Max. Temp. | |||||||

114 W/m^2 × °C | |||||||

| 10 fl. oz. | Cartridge | __ | __ | Ceramic, Glass, Metal, Plastic | Yes | 0000000 | 000000 |

| 32 fl. oz. | Cartridge | __ | __ | Ceramic, Glass, Metal, Plastic | Yes | 0000000 | 00000 |

| 1 qt. | Can | __ | __ | Ceramic, Glass, Metal, Plastic | Yes | 0000000 | 00000 |

| 1 gal. | Can | __ | __ | Ceramic, Glass, Metal, Plastic | Yes | 0000000 | 00000 |

| 5 gal. | Can | __ | __ | Ceramic, Glass, Metal, Plastic | Yes | 0000000 | 000000 |

750° F Max. Temp. | |||||||

114 W/m^2 × °C | |||||||

| 10 fl. oz. | Cartridge | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

| 32 fl. oz. | Cartridge | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

| 1 qt. | Can | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

151 W/m^2 × °C | |||||||

| 1 gal. | Can | 6 | 24 | Ceramic, Glass, Metal | No | 000000 | 00000 |

| 5 gal. | Can | 6 | 24 | Ceramic, Glass, Metal | No | 000000 | 000000 |

1,250° F Max. Temp. | |||||||

114 W/m^2 × °C | |||||||

| 10 fl. oz. | Cartridge | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

| 32 fl. oz. | Cartridge | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

| 1 qt. | Can | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 00000 |

| 1 gal. | Can | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 000000 |

| 5 gal. | Can | 1 | 24 | Ceramic, Glass, Metal, Plastic | No | 0000000 | 000000 |

2,200° F Max. Temp. | |||||||

85 W/m^2 × °C | |||||||

| 1 gal. | Pail | 1 | 24 | Metal | Yes | 0000000 | 000000 |

Electrically and Thermally Conductive Grease

A high silver content gives this grease excellent conductivity for applications where electricity and heat transfer are required. It is suitable for ESD (electrostatic discharge) and EMI (electromagnetic interference) shielding applications. Product regulations restrict sales to the listed jurisdictions/areas.

NLGI viscosity grade is a rating of a grease's consistency. NLGI 2 is about the consistency of peanut butter.

Electrical resistivity is a measure of how well a material opposes the flow of electricity. The lower the rating, the more electricity it conducts.

Thermal conductivity measures a material’s ability to transfer heat. The higher the rating, the more heat it transfers.

Grease lubricates most efficiently within the listed temperature range. Melting temperature is the point at which grease will fail and run out of equipment, leaving it to run dry.

Container | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NLGI Viscosity Grade | Base Oil | Additive | Size, fl. oz. | Type | Temp. Range, °F | Melting Temp., °F | Electrical Resistivity, ohms-cm | Thermal Conductivity | Color | Cannot Be Sold To | Each | |

Silicone Thickener | ||||||||||||

| Not Rated | Synthetic | 100% Silver | 0.2 | Syringe | -70° to 485° | 490° | 0.010 | 40 Btu/hr. × in./sq. ft./°F | Silver | Outside United States and Canada | 0000000 | 000000 |

Grease without Thickener | ||||||||||||

| 2 | Synthetic | 75% Silver | 1 | Jar | -70° to 500° | Not Rated | 0.005 | 60 Btu/hr. × in./sq. ft./°F | Silver | __ | 0000000 | 000000 |

| 2 | Synthetic | 85% Silver | 0.5 | Jar | -40° to 300° | Not Rated | 0.005 | 60 Btu/hr. × in./sq. ft./°F | Silver | __ | 0000000 | 000000 |

| 2 | Synthetic | 85% Silver | 1 | Jar | -40° to 300° | Not Rated | 0.005 | 60 Btu/hr. × in./sq. ft./°F | Silver | __ | 0000000 | 000000 |