Filter by

Length

Material

Thread Length

Tensile Strength

Hardness

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

Vibration-Resistant Threaded on Both Ends Setup Studs

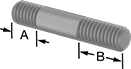

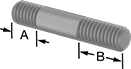

Also known as tap-end studs, inch setup studs have Class 5 friction-fit threads on one end to resist loosening and Class 2A standard threads on the other end for attaching a nut. Metric setup studs have Class SK6 friction-fit threads on one end to resist loosening and Class 6g standard threads on the other end for attaching a nut. They are ideal for machining applications where vibration can loosen clamps. They withstand sideways forces better than fully threaded studs because they have an unthreaded middle that is stronger than the threaded ends. The unthreaded middle also makes more contact with unthreaded holes, creating better alignment than a fully threaded stud. Remove studs with pliers to reuse them.

Steel

|

DIN 939—Studs that meet DIN standards meet dimensional and material requirements. Thread Length (B) includes chamfer on DIN 938 and DIN 939 studs.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. (A) | Lg. (B) | Fit (A) | Fit (B) | Lg. | Tensile Strength, psi | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8"-16 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/4" | 60,000 | — | 91563A126 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 60,000 | — | 91563A128 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 3/4" | 60,000 | — | 91563A130 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 60,000 | — | 91563A132 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 60,000 | — | 91563A133 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 60,000 | — | 91563A134 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 3/4" | 60,000 | — | 91563A135 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 60,000 | — | 91563A136 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/16"-14 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 60,000 | — | 91563A173 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 60,000 | — | 91563A177 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 60,000 | — | 91563A179 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 60,000 | — | 91563A181 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2"-13 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 60,000 | — | 91563A216 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 1 3/4" | 60,000 | — | 91563A218 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 60,000 | — | 91563A220 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 60,000 | — | 91563A221 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 60,000 | — | 91563A222 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 3/4" | 60,000 | — | 91563A223 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 60,000 | — | 91563A224 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1" | ASME Interference Class 5 | Unified Standard Class 2A | 3 1/2" | 60,000 | — | 91563A226 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 60,000 | — | 91563A228 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4 1/2" | 60,000 | — | 91563A230 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 5" | 60,000 | — | 91563A232 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8"-11 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 60,000 | — | 91563A302 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 60,000 | — | 91563A303 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 60,000 | — | 91563A304 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 60,000 | — | 91563A306 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 60,000 | — | 91563A310 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/2" | ASME Interference Class 5 | Unified Standard Class 2A | 5" | 60,000 | — | 91563A314 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/2" | ASME Interference Class 5 | Unified Standard Class 2A | 6" | 60,000 | — | 91563A316 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4"-10 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 60,000 | — | 91563A345 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 60,000 | — | 91563A347 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 3 1/2" | 60,000 | — | 91563A349 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 60,000 | — | 91563A351 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/8"-9 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 3 1/2" | 60,000 | — | 91563A386 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 60,000 | — | 91563A388 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1"-8 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/2" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 60,000 | — | 91563A390 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 2" | ASME Interference Class 5 | Unified Standard Class 2A | 5" | 60,000 | — | 91563A391 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 10 mm | Metric Interference Sk6 | Metric Class 6g | 20 mm | 80,000 | — | 91059A811 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 15 mm | Metric Interference Sk6 | Metric Class 6g | 27 mm | 80,000 | — | 91059A812 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 10 mm | Metric Interference Sk6 | Metric Class 6g | 20 mm | 80,000 | — | 91059A813 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 15 mm | Metric Interference Sk6 | Metric Class 6g | 27 mm | 80,000 | — | 91059A814 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 35 mm | 80,000 | — | 91059A815 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 35 mm | 120,000 | DIN 939 | 91059A510 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 45 mm | 120,000 | DIN 939 | 91059A515 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 60 mm | 120,000 | DIN 939 | 91059A520 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 70 mm | 120,000 | DIN 939 | 91059A525 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M10 × 1.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 37 mm | 120,000 | DIN 939 | 91059A551 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 23 mm | Metric Interference Sk6 | Metric Class 6g | 42 mm | 120,000 | DIN 939 | 91059A556 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 26 mm | Metric Interference Sk6 | Metric Class 6g | 52 mm | 120,000 | DIN 939 | 91059A561 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 26 mm | Metric Interference Sk6 | Metric Class 6g | 62 mm | 120,000 | DIN 939 | 91059A566 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M12 × 1.75 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 17 mm | Metric Interference Sk6 | Metric Class 6g | 40 mm | 120,000 | DIN 939 | 91059A605 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 27 mm | Metric Interference Sk6 | Metric Class 6g | 50 mm | 120,000 | DIN 939 | 91059A610 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 30 mm | Metric Interference Sk6 | Metric Class 6g | 60 mm | 120,000 | DIN 939 | 91059A615 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 30 mm | Metric Interference Sk6 | Metric Class 6g | 70 mm | 120,000 | DIN 939 | 91059A620 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel

|

18-8 stainless steel studs have good chemical resistance and resist rusting in humid, damp, and washdown areas. They may be mildly magnetic.

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. (A) | Lg. (B) | Fit (A) | Fit (B) | Lg. | Tensile Strength, psi | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/8"-16 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/4" | 80,000 | 92386A626 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 80,000 | 92386A628 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 3/4" | 80,000 | 92386A630 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 80,000 | 92386A632 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 80,000 | 92386A633 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 80,000 | 92386A634 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 80,000 | 92386A636 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

7/16"-14 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 5/8" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 80,000 | 92386A673 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 80,000 | 92386A677 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 80,000 | 92386A678 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 80,000 | 92386A679 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9/16" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 80,000 | 92386A681 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1/2"-13 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 1 1/2" | 80,000 | 92386A716 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 1 3/4" | 80,000 | 92386A718 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 80,000 | 92386A720 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 80,000 | 92386A721 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/4" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 80,000 | 92386A722 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 80,000 | 92386A724 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 4" | 80,000 | 92386A728 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1 1/4" | ASME Interference Class 5 | Unified Standard Class 2A | 5" | 80,000 | 92386A732 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

5/8"-11 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2" | 80,000 | 92386A802 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/4" | 80,000 | 92386A803 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 80,000 | 92386A804 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 80,000 | 92386A806 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

3/4"-10 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 7/8" | ASME Interference Class 5 | Unified Standard Class 2A | 2 1/2" | 80,000 | 92386A845 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 1" | ASME Interference Class 5 | Unified Standard Class 2A | 3" | 80,000 | 92386A847 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M4 × 0.7 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 10 mm | Metric Interference Sk6 | Metric Class 6g | 20 mm | 80,000 | 92386A911 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 15 mm | Metric Interference Sk6 | Metric Class 6g | 27 mm | 80,000 | 92386A912 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M6 × 1 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 10 mm | Metric Interference Sk6 | Metric Class 6g | 20 mm | 80,000 | 92386A913 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 27 mm | 80,000 | 92386A914 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 35 mm | 80,000 | 92386A915 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M8 × 1.25 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 35 mm | 80,000 | 92386A916 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 45 mm | 80,000 | 92386A917 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 60 mm | 80,000 | 92386A918 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 70 mm | 80,000 | 92386A919 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M10 × 1.5 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 18 mm | Metric Interference Sk6 | Metric Class 6g | 37 mm | 80,000 | 92386A921 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 42 mm | 80,000 | 92386A922 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 22 mm | Metric Interference Sk6 | Metric Class 6g | 52 mm | 80,000 | 92386A923 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 26 mm | Metric Interference Sk6 | Metric Class 6g | 62 mm | 80,000 | 92386A924 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

M12 × 1.75 mm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 17 mm | Metric Interference Sk6 | Metric Class 6g | 40 mm | 80,000 | 92386A925 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 27 mm | Metric Interference Sk6 | Metric Class 6g | 50 mm | 80,000 | 92386A926 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 30 mm | Metric Interference Sk6 | Metric Class 6g | 60 mm | 80,000 | 92386A927 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12 mm | 30 mm | Metric Interference Sk6 | Metric Class 6g | 70 mm | 80,000 | 92386A928 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||