Selecting Compatible Lead Screws and Nuts

More

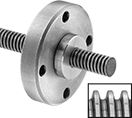

Precision Acme Lead Screws and Nuts

Pair with a motor in automated motion and positioning applications. A tight thread fit allows these lead screws and nuts to make accurate, repeatable starts and stops. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won’t unexpectedly move when the lead screw is at rest. To ensure compatibility, please select components that have the same thread direction, thread size, and number of thread starts.

Carbon steel lead screws and flanges have good machinability. Black-oxide alloy steel lead screws are hard and strong. They have mild corrosion resistance and a dark surface color. 303 and 304 stainless steel lead screws and flanges have good corrosion resistance.

932 bearing bronze and 673 bronze nuts are wear resistant. They have good machinability and fair corrosion resistance. Cast iron nuts have good machinability and high strength. PET plastic nuts are lightweight and corrosion resistant.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Lg. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Thread Fit | Hardness | Tensile Strength, psi | Each | |

1018 Carbon Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 5/8"-10 | 3 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 126 | 64,000 | 000000000 | 000000 |

| 5/8"-10 | 6 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 126 | 64,000 | 000000000 | 00000 |

Black-Oxide 4140 Alloy Steel | ||||||||||

| 5/8"-10 | 3 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 271 | 125,000 | 000000000 | 00000 |

| 5/8"-10 | 6 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 271 | 125,000 | 000000000 | 000000 |

304 Stainless Steel | ||||||||||

| 5/8"-10 | 3 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 150 | 72,000 | 000000000 | 00000 |

| 5/8"-10 | 6 ft. | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 150 | 72,000 | 000000000 | 000000 |

| Thread Size | Lg. | Lg., ft. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Thread Fit | Hardness | Tensile Strength, psi | Each | |

1018 Carbon Steel | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/8"-10 | 3 ft. | 3 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 126 | 64,000 | 000000000 | 000000 |

| 5/8"-10 | 6 ft. | 6 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 126 | 64,000 | 000000000 | 00000 |

Black-Oxide 4140 Alloy Steel | |||||||||||

| 5/8"-10 | 3 ft. | 3 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 271 | 125,000 | 000000000 | 00000 |

| 5/8"-10 | 6 ft. | 6 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 271 | 125,000 | 000000000 | 000000 |

304 Stainless Steel | |||||||||||

| 5/8"-10 | 3 ft. | 3 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 150 | 72,000 | 000000000 | 00000 |

| 5/8"-10 | 6 ft. | 6 | 1 | 1:1 | 0.1" | ±0.009" per ft. | Class 2C | Brinell 150 | 72,000 | 000000000 | 000000 |

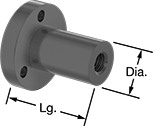

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

Cast Iron | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Brinell 217 | Not Rated | __ | 000000000 | 000000 |

932 Bearing Bronze | |||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Brinell 65 | 2,000 | __ | 00000000 | 00000 |

PET Plastic | |||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

Cast Iron | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Brinell 217 | Not Rated | __ | 000000000 | 000000 |

932 Bearing Bronze | |||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Brinell 65 | 2,000 | __ | 00000000 | 00000 |

PET Plastic | |||||||||||

| 5/8"-10 | 1 1/4" | 1.859" | 1 | 1:1 | 0.1" | Class 2C | Not Rated | 1,000 | 15° to 175° | 00000000 | 00000 |

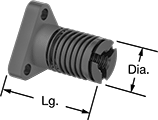

Combine externally threaded nuts with a flange to create a custom flange nut.

External Thread | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Temperature Range, °F | Each | |

673 Bronze | |||||||||||||

| 5/8"-10 | 1" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Brinell 70 | Not Rated | __ | 000000000 | 000000 |

PET Plastic | |||||||||||||

| 5/8"-10 | 1" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Not Rated | 1,000 | 15° to 175° | 000000000 | 00000 |

Combine externally threaded nuts with a flange to create a custom flange nut.

External Thread | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Thread Size | Lg. | Dia. | No. of Thread Starts | Speed Ratio | Travel Distance per Turn | Size | Lg. | Thread Fit | Hardness | Dynamic Thrust Load Cap., lbs. | Each | |

673 Bronze | ||||||||||||

| 5/8"-10 | 1" | 1.125" | 1 | 1:1 | 0.1" | 15/16"-16 | 1/2" | Class 2C | Brinell 70 | Not Rated | 000000000 | 000000 |

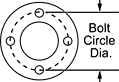

Thread onto an externally threaded acme nut to create a custom flange nut.

Carbon steel flanges have good machinability. However, they will rust when exposed to moisture. Black-oxide carbon steel flanges have mild corrosion resistance in dry environments and a dark surface color. 303 stainless steel flanges have good corrosion resistance.

Ultra-Precision Lead Screws and Nuts

Operating with less backlash (play) than Precision Acme Lead Screws and Nuts, these provide increased nut life and more reliable movement in automated systems. Also known as single-start and self-locking lead screws and nuts, they have a single thread that runs the length of the screw. The nut travels only when the screw turns, so your system won’t unexpectedly move when the lead screw is at rest. All components are corrosion resistant for use in harsh environments. To ensure compatibility, select components that have the same thread type, thread size, and number of thread starts.

Travel distance per turn, also known as screw lead, is the distance a nut moves with one revolution of the lead screw.

| Thread Size | Lg. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn | Accuracy for Travel Distance per Turn | Hardness | Tensile Strength, psi | Each | |

303 Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 5/8"-10 | 3 ft. | 1 | Rounded Acme | 1:1 | 0.1" | ±0.0006" per in. | Brinell 160 | 90,000 | 00000000 | 0000000 |

| 5/8"-10 | 6 ft. | 1 | Rounded Acme | 1:1 | 0.1" | ±0.0006" per in. | Brinell 160 | 90,000 | 00000000 | 000000 |

Flange nuts with wear-compensating internal O-ring or wear-compensating spring maintain a tight fit even when their threads begin to wear. They resist backlash to maintain accuracy over time, which is important in positioning applications such as 3D printing and robotics.

Flange | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

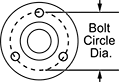

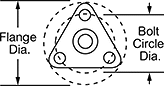

| Thread Size | Lg. | Dia. | Dia. | Thick. | No. of Thread Starts | Thread Type | Speed Ratio | Travel Distance per Turn | Bolt Circle Dia. | Tensile Strength, psi | Dynamic Thrust Load Cap., lbs. | Each | ||

Acetal Plastic | ||||||||||||||

| B | 5/8"-10 | 1 1/2" | 0.875" | 1 1/2" | 3/16" | 1 | Rounded Acme | 1:1 | 0.1" | 1 3/16" | 9,700 | 220 | 00000000 | 000000 |

Acetal Plastic with Wear-Compensating Spring | ||||||||||||||

| C | 5/8"-10 | 2" | 1.063" | 1 51/64" | 17/64" | 1 | Rounded Acme | 1:1 | 0.1" | 1 3/8" | 9,700 | 35 | 00000000 | 00000 |

Clamping Acme Lead Screw Collars

Thread these one-piece collars onto an Acme lead screw to separate and position components, or use them as an end stop to limit travel. Tighten the clamping screw to secure.

To ensure compatibility, please select a collar that has the same thread type, direction, size, and number of thread starts as your lead screw.

Black-oxide carbon steel collars have mild corrosion resistance. 303 stainless steel collars have good corrosion resistance.

Two-Piece Clamping Acme Lead Screw Collars

Mount these two-piece collars anywhere on an Acme lead screw without removing components. Use them to separate and position components or as an end stop to limit travel. Tighten the clamping screw to secure.

To ensure compatibility, please select a collar that has the same thread type, direction, size, and number of thread starts as your lead screw.

Black-oxide carbon steel collars have mild corrosion resistance.

| Thread Size | OD | Wd. | No. of Thread Starts | Hardness | Each | |

Right-Hand Threaded | ||||||

|---|---|---|---|---|---|---|

Black-Oxide 1215 Carbon Steel | ||||||

| 5/8"-10 | 1 5/16" | 7/16" | 1 | Brinell 167 | 0000000 | 000000 |