Filter by

Weight Capacity

Load Securement Type

Base Material

Inner Ring Width

Ring Material

Ring Thickness

Ring Height

Base Width

Mounting Hole Center-to-Center Length

Base Length

Ring Finish

Track Type

DFARS Specialty Metals

Export Control Classification Number (ECCN)

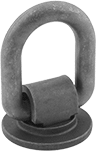

Tie-Down Rings

|  |  |  |

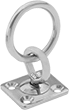

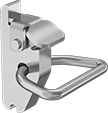

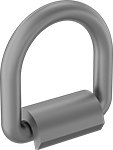

Style A | Style B | Style C | Style D |

|  |  |  |

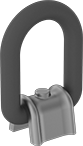

Style E | Style F | Style G | Style H |

|  |  |  |

Style J | Style K | Style L | Style M |

Ring | Base | Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Dia. | Lg. | Wd. | Material | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. Wd. | Ctr.-to-Ctr. Lg. | For Mounting Screw Size | 1-99 | 100-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 500 | 2" | 2 1/4" | 1/4" | D-Ring | — | 1 5/16" | 1 5/8" | Zinc-Plated Steel | No | 1 | 13/32" | — | — | 3/8" | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1,000 | 1 7/16" | 1 1/2" | 1/4" | D-Ring | — | 1 5/8" | 1 3/8" | Zinc-Plated Steel | No | 1 | 7/16" | — | — | 7/16" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 200 | 1 9/16" | 1 13/16" | 3/16" | D-Ring | 4 1/8" | — | — | Zinc-Plated Steel | No | 2 | 9/32", 13/32" | — | 1 1/16" | 1/4" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 500 | 2" | 2 1/4" | 1/4" | D-Ring | 4 1/16" | — | — | Polypropylene | No | 3 | 9/32", 13/32" | — | 1 3/16" | 3/8" | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 400 | 1 1/2" | 1 11/16" | 1/4" | D-Ring | — | 2 3/16" | 1 1/4" | Zinc-Plated Steel | No | 2 | 1/4" | — | 1 1/4" | 1/4" | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 800 | 1" | 1 13/16" | 1/4" | D-Ring | — | 2 1/8" | 13/16" | Zinc-Plated Steel | No | 2 | 9/32" | — | 1 3/8" | 1/4" | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1,000 | 1 1/2" | 1 3/8" | 1/4" | D-Ring | — | 1 5/8" | 1 1/4" | Zinc-Plated Steel | No | 2 | 1/4" | — | 15/16" | 1/4" | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1,000 | 1 1/2" | 1 13/16" | 1/4" | D-Ring | — | 1 9/16" | 1 1/4" | Zinc-Plated Steel | No | 2 | 1/4" | — | 7/8" | 1/4" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1,500 | 2" | 2 1/8" | 1/4" | D-Ring | — | 2 1/8" | 1 7/8" | Zinc-Plated Steel | No | 2 | 1/4" | — | 1 3/8" | 1/4" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | 3,500 | 2 5/16" | 1 3/4" | 5/16" | D-Ring | — | 2 1/8" | 1 7/8" | Zinc-Plated Steel | No | 4 | 1/4" | 1 1/4" | 1 1/8" | 1/4" | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| J | 3,500 | 3 3/16" | 3 3/4" | 5/16" | D-Ring | — | 2 3/16" | 2 1/2" | Zinc-Plated Steel | No | 4 | 1/4" | 1 3/8" | 1 3/4" | 1/4" | 0000000 | 00000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 800 | 1 29/32" | 2 1/8" | 1/4" | D-Ring | — | 1 9/16" | 1 1/2" | Zinc-Plated Steel | No | 1 | 13/32" | — | — | 3/8" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | 6,940 | 1 9/16" | 5 1/8" | 11/16" | Link Ring | — | 5 1/8" | 1 1/2" | Powder-Coated Steel | Yes | 2 | 11/16" | — | 3 1/2" | M16 | 0000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| L | 11,680 | 1 15/16" | 6 3/4" | 7/8" | Link Ring | — | 6 1/2" | 1 7/8" | Powder-Coated Steel | Yes | 2 | 7/8" | — | 4 1/2" | M20 | 0000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| K | 4,080 | 2 3/8" | 3 1/2" | 1/2" | D-Ring | — | 3" | 1 3/4" | Steel | No | 2 | 13/32" | — | 2" | 3/8" | 0000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 400 | 1 1/2" | 1 1/2" | 3/16" | D-Ring | — | 1 5/16" | 1 1/8" | 18-8 Stainless Steel | No | 1 | 3/8" | — | — | 3/8" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 50 | 13/16" | 7/8" | 1/8" | D-Ring | — | 13/16" | 11/16" | 316 Stainless Steel | No | 1 | 1/4" | — | — | No. 14 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 210 | 1 17/32" | 1 5/16" | 0.23" | D-Ring | — | 2" | 1 1/8" | 316 Stainless Steel | No | 2 | 1/4" | — | 1 11/32" | No. 14 | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 400 | 1" | 1 1/2" | 3/16" | D-Ring | — | 2" | 5/8" | 316 Stainless Steel | No | 2 | 9/32" | — | 1 3/8" | 1/4" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | 1,200 | 1 3/32" | 1 1/8" | 1/4" | D-Ring | — | 1 1/2" | 1" | 316 Stainless Steel | No | 2 | 7/32" | — | 15/16" | No. 10 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | 2,000 | 1 15/32" | 1 5/16" | 5/16" | D-Ring | — | 1 15/16" | 1 3/8" | 316 Stainless Steel | No | 2 | 5/16" | — | 1 1/4" | No. 20 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| F | 4,000 | 1 15/16" | 1 9/16" | 3/8" | D-Ring | — | 2 1/2" | 1 3/4" | 316 Stainless Steel | No | 2 | 13/32" | — | 1 5/8" | 3/8" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G | 1,000 | 1 1/2" | 1 1/2" | 1/4" | D-Ring | — | 2 1/4" | 2" | 316 Stainless Steel | No | 3 | 9/32" | 1 1/2" | 1 1/4" | 1/4" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| G | 1,500 | 2" | 2 1/8" | 5/16" | D-Ring | — | 3" | 2 1/2" | 316 Stainless Steel | No | 3 | 11/32" | 2" | 1 1/2" | 5/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 1,500 | 1 1/16" | 1 3/16" | 1/4" | D-Ring | — | 1 5/8" | 1 3/4" | 316 Stainless Steel | No | 3 | 1/4" | 1 1/16" | 1 1/16" | M6 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 2,500 | 1 3/8" | 1 3/8" | 5/16" | D-Ring | — | 2 3/16" | 2 1/4" | 316 Stainless Steel | No | 3 | 5/16" | 1 3/8" | 1 3/8" | M8 | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| H | 5,000 | 1 3/4" | 2 1/16" | 3/8" | D-Ring | — | 2 5/8" | 2 15/16" | 316 Stainless Steel | No | 3 | 3/8" | 1 3/4" | 1 3/4" | M10 | 00000000 | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M | 5,620 | 1 5/16" | 3 1/4" | 11/16" | Round Ring | — | 2" | 1 3/4" | 316 Stainless Steel | No | 1 | 3/8" | — | — | — | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Weld-On Tie-Down Rings

|  |  |  |

Style A | Style B | Style C | Style D |

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Ht. | Thk. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2,000 | 2 9/16" | 2 11/16" | 3/8" | D-Ring | 2" | 15/16" | — | 1/4" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Blue Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,600 | 1 1/2" | 3 3/16" | 1/2" | D-Ring | 1 3/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 11,000 | 1 3/4" | 3 7/16" | 9/16" | D-Ring | 1 5/8" | 1 15/16" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 17,600 | 2" | 4 1/16" | 11/16" | D-Ring | 1 13/16" | 2 3/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 29,800 | 2 11/16" | 5 11/16" | 15/16" | D-Ring | 2 1/2" | 3 1/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 44,100 | 2 3/4" | 6" | 1 1/16" | D-Ring | 2 1/2" | 3 5/8" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 17,600 | 1 7/8" | 3 3/8" | 9/16" | D-Ring | 5 1/4" | 2 5/8" | 1 1/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 29,800 | 2 3/8" | 4 1/16" | 13/16" | D-Ring | 6 11/16" | 3 1/8" | 1 7/16" | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Red Painted Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 2,100 | 1 7/16" | 2 9/16" | 0.43" | D-Ring | 1 1/4" | 1 1/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3,500 | 1 5/8" | 3 1/16" | 0.55" | D-Ring | 1 1/2" | 1 1/2" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 7,100 | 1 7/8" | 3 3/4" | 0.71" | D-Ring | 1 3/4" | 1 3/4" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 12,000 | 2 5/8" | 5 3/8" | 0.94" | D-Ring | 2 3/8" | 2 3/8" | — | — | Alloy Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 18,100 | 2 13/16" | 5 3/4" | 1.1" | D-Ring | 2 11/16" | 2 9/16" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 34,200 | 4 3/4" | 8 1/8" | 1 1/2" | D-Ring | 3 3/4" | 4 1/4" | — | — | Alloy Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 3/8" | 3 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 11/16" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,080 | 2 1/2" | 5 1/2" | 1/2" | D-Ring | 2" | 1 5/16" | — | 3/8" | Low-Carbon Steel | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,130 | 3" | 4 1/4" | 5/8" | D-Ring | 2 1/2" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 9,120 | 3" | 4 1/2" | 3/4" | D-Ring | 2 1/4" | 1 5/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 15,500 | 3" | 6" | 1" | D-Ring | 2 1/4" | 2 1/8" | — | 3/8" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 15,500 | 3" | 5 1/2" | 1" | Angled-Bend D-Ring | 2 1/4" | 2 1/8" | — | 1/2" | Low-Carbon Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3,000 | 2 5/16" | 3 5/8" | 1/2" | D-Ring | 2" | 1 3/8" | — | 1/4" | 316 Stainless Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 4,500 | 2 15/16" | 4 1/2" | 5/8" | D-Ring | 2 9/16" | 1 3/4" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,500 | 2 15/16" | 4 5/8" | 3/4" | D-Ring | 2 9/16" | 1 7/8" | — | 3/8" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 8,500 | 3" | 5 1/8" | 1" | D-Ring | 2 9/16" | 2 1/8" | — | 1/2" | 316 Stainless Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Recessed Tie-Down Rings

|  |  |

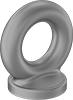

Round Ring | D-Ring | D-Ring and Straight Ring |

For Cutout | Ring | Base | Mounting Holes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Dp. | Lg. | Wd. | Dia. | For Max. Webbing Wd. | Inner Wd. | Ht. | Thk. | Lg. | Wd. | Dia. | Material | Mounting Fasteners Included | Dia. | Ctr.-to-Ctr. Wd. | Ctr.-to-Ctr. Lg. | No. of | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1,660 | 1" | 2 7/8" | 2 7/8" | — | — | 1 3/8" | 1 3/4" | 7/16" | 4 7/8" | 4 1/2" | — | Zinc-Plated Steel | No | 13/32" | 3" | 3 1/4" | 4 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

D-Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,000 | 1" | — | — | 4 1/2" | — | 3 3/8" | 1 13/16" | 5/16" | — | — | 6 1/4" | Zinc-Plated Steel | No | 11/32" | 3 13/16" | 3 13/16" | 4 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

D-Ring and Straight Ring | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 830 | 1" | — | — | 4 1/2" | 2" | 2 7/8", 2 1/8" | 1 1/2", 1 3/16" | 3/8", 3/8" | — | — | 6 1/4" | Zinc-Plated Steel | No | 11/32" | 3 13/16" | 3 13/16" | 4 | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Swiveling Weld-On Tie-Down Rings

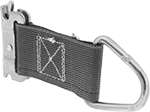

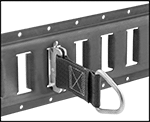

Tie-Down Rings for Quick-Adjust L-Tracks

|  |  |  |

Round Rings for 1 Mounting Point | Round Rings for 2 Mounting Points | D-Rings for 1 Mounting Point |

Swiveling Tie-Down Rings

Ring | Base | Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Material | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. Wd. | Ctr.-to-Ctr. Lg. | For Mounting Screw Size | 1-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 200 | 5/8" | 1 5/16" | 3/16" | Round Ring | 1 5/16" | 1 3/16" | 18-8 Stainless Steel | No | 4 | 5/32" | 7/8" | 3/4" | No. 8 | 0000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 300 | 3/4" | 1 19/32" | 1/4" | Round Ring | 1 9/16" | 1 5/16" | 18-8 Stainless Steel | No | 4 | 5/32" | 1" | 3/4" | No. 8 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 480 | 3/4" | 1 23/32" | 5/16" | Round Ring | 2" | 1 9/16" | 18-8 Stainless Steel | No | 4 | 7/32" | 1 3/8" | 1" | No. 10 | 0000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 200 | 1 3/16" | 2 1/2" | 3/16" | Round Ring | 1 5/16" | 1 3/16" | 18-8 Stainless Steel | No | 4 | 3/16" | 7/8" | 3/4" | No. 8 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 300 | 1 5/8" | 3 5/32" | 1/4" | Round Ring | 1 9/16" | 1 5/16" | 18-8 Stainless Steel | No | 4 | 1/4" | 1" | 3/4" | No. 8 | 00000000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 480 | 2" | 3 3/4" | 5/16" | Round Ring | 1 3/4" | 1 9/16" | 18-8 Stainless Steel | No | 4 | 5/16" | 1 3/8" | 1" | No. 10 | 00000000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Ready Tie-Down Rings

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Thk. | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Not Rated | 1/2" | 13/16" | 3/16" | Angled-Bend D-Ring | 1 1/4" | 1 1/4" | 1/16" | 316 Stainless Steel | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Dimpled Tie-Down Rings

Ring | Base | Mounting Holes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap., lb. | Inner Wd. | Ht. | Thk. | Style | Lg. | Wd. | Material | Mounting Fasteners Included | No. of | Dia. | 1-49 | 50-Up | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5,600 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | Zinc-Plated Steel | No | 1 | 7/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 6,700 | 1 1/4" | 1 3/8" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | 304 Stainless Steel | No | 1 | 7/16" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5,620 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | 316 Stainless Steel | No | 1 | 7/16" | 00000000 | 0000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5,620 | 1 1/8" | 1 3/16" | 1/2" | Round Ring | 2 1/2" | 1 3/4" | 316 Stainless Steel | No | 1 | 7/16" | 00000000 | 00000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

E-Track Tie-Down Rings

Fixed Weld-On Tie-Down Rings

Ring | Base | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Wt. Cap. | Inner Wd. | Ht. | Thk. | Style | Dia. | Lg. | Wd. | Material | 1-24 | 25-99 | 100-Up | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/4" | 3/4" | 3/16" | Round Ring | 5/8" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/8" | 1" | 1/4" | Round Ring | 7/8" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 1" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 5/8" | 3/8" | Round Ring | 1 1/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2 5/16" | 9/16" | Round Ring | 1 7/16" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 3/16" | 2 3/8" | 7/16" | Round Ring | 1 11/16" | — | — | Low-Carbon Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 3/4" | 11/16" | Round Ring | 1 3/4" | — | — | Low-Carbon Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | Not Rated | 5/8" | 7/8" | 1/4" | Round Ring | — | 1 1/8" | 1 1/8" | Alloy Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1/2" | 1 1/16" | 3/16" | Round Ring | 3/8" | — | — | 316 Stainless Steel | 000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 5/8" | 1 5/16" | 1/4" | Round Ring | 9/16" | — | — | 316 Stainless Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 3/4" | 1 9/16" | 5/16" | Round Ring | 5/8" | — | — | 316 Stainless Steel | 0000000 | 0000 | 0000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1" | 2" | 3/8" | Round Ring | 7/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/4" | 2 1/2" | 1/2" | Round Ring | 1" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | Not Rated | 1 1/2" | 3 1/4" | 5/8" | Round Ring | 1 3/8" | — | — | 316 Stainless Steel | 0000000 | 00000 | 00000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adhesive-Back Tie-Down Rings

Ring | Base | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Inner Wd. | Style | Lg. | Wd. | Material | Adhesive Type | Reaches Full Strength, hr. | Begins to Harden, min. | Temp. Range, ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene Rope | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | 2 1/2" | D-Ring | 3 1/8" | 2 1/2" | EVA Foam | Acrylic | 72 | 20 | -95 to 165 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Magnetic Tie-Down Rings

Ring | Handle | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wt. Cap., lb. | Inner Wd. | Style | Lg. | Wd. | Overall Ht. | Housing Material | Material | Color | Magnet Type | For Max. Surface Thk. | Each | |||

| 35 | 1/2" | Round Ring | 4 1/8" | 1 13/16" | 2 3/4" | Nickel-Plated Steel | Powder-Coated Aluminum | Black | Rare Earth | 1/4" | 000000 | 0000000 | ||