Hydraulic Cylinders

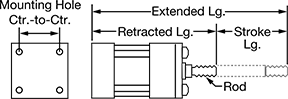

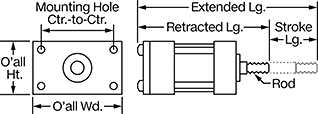

For easy interchangeability, the mounting footprint of these cylinders meets NFPA and JIC (Joint Industrial Congress) industry standards. All have two hydraulic ports: one to extend the piston rod and another to retract it. Cylinders with no cushion have a compact size. Those with an adjustable cushion reduce shock to internal components and lessen machine noise.

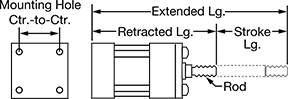

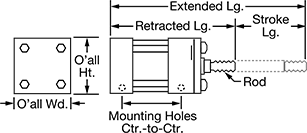

O'all | Mounting Hole | Inlet/Outlet Connection— NPT | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg. | Max. Push Force, lbs. | Max. Pull Force, lbs. | Retracted Lg. | Extended Lg. | Rod Thread Size | Wd. | Ht. | Ctr.-to-Ctr. | Thread Size | Pipe Size | Dash Size | Body Material | Max. Pressure, psi | Air Cushion Type | Each | |

NFPA and JIC Heavy Duty Mounting Pattern | ||||||||||||||||

1 1/2" Bore Dia. | ||||||||||||||||

| 1" | 4,420 | 3,650 | 7 3/8" | 8 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 0000000 |

| 2" | 4,420 | 3,650 | 8 3/8" | 10 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 3" | 4,420 | 3,650 | 9 3/8" | 12 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 4" | 4,420 | 3,650 | 10 3/8" | 14 3/4" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 000000 |

| 5" | 4,420 | 3,650 | 11 3/8" | 16 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 000000 |

| 6" | 4,420 | 3,650 | 12 3/8" | 18 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 7" | 4,420 | 3,650 | 13 3/8" | 20 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 8" | 4,420 | 3,650 | 14 3/8" | 22 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 9" | 4,420 | 3,650 | 15 3/8" | 24 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 10" | 4,420 | 3,650 | 16 3/8" | 26 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 11" | 4,420 | 3,650 | 17 3/8" | 28 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 12" | 4,420 | 3,650 | 18 3/8" | 30 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

2" Bore Dia. | ||||||||||||||||

| 1" | 7,850 | 5,900 | 8 1/8" | 9 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 2" | 7,850 | 5,900 | 9 1/8" | 11 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 3" | 7,850 | 5,900 | 10 1/8" | 13 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 4" | 7,850 | 5,900 | 11 1/8" | 15 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 000000 |

| 5" | 7,850 | 5,900 | 12 1/8" | 17 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 000000 |

| 6" | 7,850 | 5,900 | 13 1/8" | 19 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 7" | 7,850 | 5,900 | 14 1/8" | 21 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 8" | 7,850 | 5,900 | 15 1/8" | 23 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 9" | 7,850 | 5,900 | 16 1/8" | 25 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 10" | 7,850 | 5,900 | 17 1/8" | 27 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 000000 |

| 11" | 7,850 | 5,900 | 18 1/8" | 29 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 7,850 | 5,900 | 19 1/8" | 31 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

2 1/2" Bore Dia. | ||||||||||||||||

| 1" | 12,270 | 10,320 | 8 1/4" | 9 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 2" | 12,270 | 10,320 | 9 1/4" | 11 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 3" | 12,270 | 10,320 | 10 1/4" | 13 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 000000000 | 000000 |

| 4" | 12,270 | 10,320 | 11 1/4" | 15 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 5" | 12,270 | 10,320 | 12 1/4" | 17 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 6" | 12,270 | 10,300 | 13 1/4" | 19 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 12,270 | 10,300 | 14 1/4" | 21 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 12,270 | 10,300 | 15 1/4" | 23 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 12,270 | 10,300 | 16 1/4" | 25 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 12,270 | 10,300 | 17 1/4" | 27 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 12,270 | 10,300 | 18 1/4" | 29 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 12,270 | 10,300 | 19 1/4" | 31 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

3 1/4" Bore Dia. | ||||||||||||||||

| 1" | 20,750 | 17,020 | 9 3/4" | 10 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 2" | 20,750 | 17,020 | 10 3/4" | 12 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 3" | 20,750 | 17,020 | 11 3/4" | 14 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 4" | 20,750 | 17,020 | 12 3/4" | 16 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 5" | 20,750 | 17,020 | 13 3/4" | 18 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 6" | 20,750 | 17,020 | 14 3/4" | 20 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 20,750 | 17,020 | 15 3/4" | 22 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 20,750 | 17,020 | 16 3/4" | 24 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 20,750 | 17,020 | 17 3/4" | 26 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 20,750 | 17,020 | 18 3/4" | 28 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 20,750 | 17,020 | 19 3/4" | 30 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 20,750 | 17,020 | 20 3/4" | 32 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

4" Bore Dia. | ||||||||||||||||

| 1" | 31,420 | 25,400 | 10 5/8" | 11 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 2" | 31,420 | 25,400 | 11 5/8" | 13 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 3" | 31,420 | 25,400 | 12 5/8" | 15 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 000000000 | 00000000 |

| 4" | 31,420 | 25,400 | 13 5/8" | 17 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 5" | 31,420 | 25,400 | 14 5/8" | 19 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 000000000 | 00000000 |

| 6" | 31,420 | 25,400 | 15 5/8" | 21 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 31,420 | 25,400 | 16 5/8" | 23 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 31,420 | 25,400 | 17 5/8" | 25 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 31,420 | 25,400 | 18 5/8" | 27 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 31,420 | 25,400 | 19 5/8" | 29 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 31,420 | 25,400 | 20 5/8" | 31 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 31,420 | 25,400 | 21 5/8" | 33 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

NFPA Light Duty MS 4 Mounting Pattern | ||||||||||||||||

1 1/2" Bore Dia. | ||||||||||||||||

| 1" | 2,650 | 2,190 | 6 5/8" | 7 5/8" | 7/16"-20 | 2" | 2" | 3 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 2" | 2,650 | 2,190 | 7 5/8" | 9 5/8" | 7/16"-20 | 2" | 2" | 4 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 3" | 2,650 | 2,190 | 8 5/8" | 11 5/8" | 7/16"-20 | 2" | 2" | 5 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 4" | 2,650 | 2,190 | 9 5/8" | 13 5/8" | 7/16"-20 | 2" | 2" | 6 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 5" | 2,650 | 2,190 | 10 5/8" | 15 5/8" | 7/16"-20 | 2" | 2" | 7 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 6" | 2,650 | 2,190 | 11 5/8" | 17 5/8" | 7/16"-20 | 2" | 2" | 8 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 7" | 2,650 | 2,190 | 12 5/8" | 19 5/8" | 7/16"-20 | 2" | 2" | 9 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 8" | 2,650 | 2,190 | 13 5/8" | 21 5/8" | 7/16"-20 | 2" | 2" | 10 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 000000 |

| 12" | 2,650 | 2,190 | 17 5/8" | 29 5/8" | 7/16"-20 | 2" | 2" | 14 1/4" | 1/4"-20 | 3/8 | 06 | Brass | 1,500 | No Cushion | 000000 | 00000000 |

2" Bore Dia. | ||||||||||||||||

| 1" | 3,760 | 3,390 | 6 11/16" | 7 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 3 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 2" | 3,760 | 3,390 | 7 11/16" | 9 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 4 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 00000000 |

| 3" | 3,760 | 3,390 | 8 11/16" | 11 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 5 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 4" | 3,760 | 3,390 | 9 11/16" | 13 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 6 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 5" | 3,760 | 3,390 | 10 11/16" | 15 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 7 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 6" | 3,760 | 3,390 | 11 11/16" | 17 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 8 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 00000000 |

| 7" | 3,760 | 3,390 | 12 11/16" | 19 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 9 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 8" | 3,760 | 3,390 | 13 11/16" | 21 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 10 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 000000 |

| 12" | 3,760 | 3,390 | 17 11/16" | 29 11/16" | 7/16"-20 | 2 1/2" | 2 1/2" | 14 1/4" | 5/16"-18 | 3/8 | 06 | Brass | 1,200 | No Cushion | 0000000 | 00000000 |

| For Bore Dia. | Each | |

| 1 1/2" | 00000000 | 000000 |

| 2", 2 1/2" | 00000000 | 00000 |

| 3 1/4" | 00000000 | 000000 |

| 4" | 00000000 | 000000 |

| For Bore Dia. | Mounting Fasteners Included | Each | |

| 1 1/2" | No | 00000000 | 000000 |

| 2", 2 1/2" | No | 00000000 | 00000 |

| 3 1/4" | No | 00000000 | 000000 |

| 4" | No | 00000000 | 000000 |

| For Bore Dia. | Each | |

| 1 1/2" | 00000000 | 000000 |

| 2", 2 1/2" | 00000000 | 00000 |

| 3 1/4" | 00000000 | 00000 |

| 4" | 00000000 | 00000 |

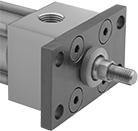

Sensor-Ready Hydraulic Cylinders

These cylinders have a magnetic piston that can be used with tie rod-mount proximity switches (sold separately) to electronically indicate piston position. For easy interchangeability, their mounting footprint meets NFPA or NFPA and JIC (Joint Industrial Congress) industry standards. All have two hydraulic ports: one to extend the piston rod and another to retract it. Cylinders with an adjustable cushion reduce shock to internal components and lessen machine noise. Those with no cushion have a compact size.

O'all | Mounting Hole | Inlet/Outlet Connection— NPT | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg. | Max. Push Force, lbs. | Max. Pull Force, lbs. | Retracted Lg. | Extended Lg. | Rod Thread Size | Wd. | Ht. | Ctr.-to-Ctr. | Thread Size | Pipe Size | Dash Size | Body Material | Max. Pressure, psi | Air Cushion Type | Each | |

NFPA and JIC Heavy Duty Mounting Pattern | ||||||||||||||||

1 1/2" Bore Dia. | ||||||||||||||||

| 3" | 4,420 | 3,650 | 9 3/8" | 12 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | No Cushion | 00000000 | 0000000 |

| 4" | 4,420 | 3,650 | 10 3/8" | 14 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 5" | 4,420 | 3,650 | 11 3/8" | 16 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 6" | 4,420 | 3,650 | 12 3/8" | 18 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 4,420 | 3,650 | 13 3/8" | 20 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 4,420 | 3,650 | 14 3/8" | 22 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 4,420 | 3,650 | 15 3/8" | 24 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 4,420 | 3,650 | 16 3/8" | 26 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 4,420 | 3,650 | 17 3/8" | 28 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 4,420 | 3,650 | 18 3/8" | 30 3/8" | 7/16"-20 | 2 1/2" | 2 1/2" | 1 5/8" | 3/8"-24 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

2" Bore Dia. | ||||||||||||||||

| 3" | 7,850 | 5,900 | 10 1/8" | 13 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 00000000 | 00000000 |

| 4" | 7,850 | 5,900 | 11 1/8" | 15 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 5" | 7,850 | 5,900 | 12 1/8" | 17 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 6" | 7,850 | 5,900 | 13 1/8" | 19 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 7,850 | 5,900 | 14 1/8" | 21 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 7,850 | 5,900 | 15 1/8" | 23 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 7,850 | 5,900 | 16 1/8" | 25 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 7,850 | 5,900 | 17 1/8" | 27 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 7,850 | 5,900 | 18 1/8" | 29 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 7,850 | 5,900 | 19 1/8" | 31 1/8" | 3/4"-16 | 3" | 3" | 2 1/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

2 1/2" Bore Dia. | ||||||||||||||||

| 3" | 12,270 | 10,300 | 10 1/4" | 13 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | No Cushion | 00000000 | 00000000 |

| 4" | 12,270 | 10,300 | 11 1/4" | 15 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 5" | 12,270 | 10,300 | 12 1/4" | 17 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 6" | 12,270 | 10,300 | 13 1/4" | 19 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 12,270 | 10,300 | 14 1/4" | 21 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 12,270 | 10,300 | 15 1/4" | 23 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 12,270 | 10,300 | 16 1/4" | 25 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 12,270 | 10,300 | 17 1/4" | 27 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 12,270 | 10,300 | 18 1/4" | 29 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 12,270 | 10,300 | 19 1/4" | 31 1/4" | 3/4"-16 | 3 1/2" | 3 1/2" | 2 9/16" | 1/2"-20 | 1/2 | 08 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

3 1/4" Bore Dia. | ||||||||||||||||

| 3" | 20,750 | 17,020 | 11 3/4" | 14 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 00000000 | 00000000 |

| 4" | 20,750 | 17,020 | 12 3/4" | 16 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 5" | 20,750 | 17,020 | 13 3/4" | 18 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 6" | 20,750 | 17,020 | 14 3/4" | 20 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 20,750 | 17,020 | 15 3/4" | 22 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 20,750 | 17,020 | 16 3/4" | 24 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 20,750 | 17,020 | 17 3/4" | 26 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 20,750 | 17,020 | 18 3/4" | 28 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 20,750 | 17,020 | 19 3/4" | 30 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 20,750 | 17,020 | 20 3/4" | 32 3/4" | 1"-14 | 4 1/2" | 4 1/2" | 3 1/4" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

4" Bore Dia. | ||||||||||||||||

| 3" | 31,420 | 25,400 | 12 5/8" | 15 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | No Cushion | 00000000 | 00000000 |

| 4" | 31,420 | 25,400 | 13 5/8" | 17 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 5" | 31,420 | 25,400 | 14 5/8" | 19 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 6" | 31,420 | 25,400 | 15 5/8" | 21 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 7" | 31,420 | 25,400 | 16 5/8" | 23 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 8" | 31,420 | 25,400 | 17 5/8" | 25 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 9" | 31,420 | 25,400 | 18 5/8" | 27 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 10" | 31,420 | 25,400 | 19 5/8" | 29 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 11" | 31,420 | 25,400 | 20 5/8" | 31 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

| 12" | 31,420 | 25,400 | 21 5/8" | 33 5/8" | 1 1/4"-12 | 5" | 5" | 3 13/16" | 5/8"-18 | 3/4 | 12 | Steel | 2,500 | Adjustable Cushion | 00000000 | 00000000 |

Send an electronic signal to your system when the piston reaches a certain location. Mount one or two of these sensors on a cylinder tie rod; they must be flush against the cylinder tube. An LED indicator shows the piston location. These switches are PNP (also called "sourcing") output, so they send energy onwards. PNP output is most common in solid-state relays and PLCs used in the United States and Europe.

| For Bore Dia. | For Cylinder Body Material | Each | |

| 1 1/2"-4" | Steel | 000000 | 0000000 |

| For Bore Dia. | Each | |

Clevis Rod Ends | ||

|---|---|---|

| 1 1/2" | 00000000 | 000000 |

| 2", 2 1/2" | 00000000 | 00000 |

| 3 1/4" | 00000000 | 000000 |

| 4" | 00000000 | 000000 |

Pivot Brackets | ||

| 1 1/2" | 00000000 | 00000 |

| 2", 2 1/2" | 00000000 | 00000 |

| 3 1/4" | 00000000 | 000000 |

| 4" | 00000000 | 000000 |

Clevis Pins | ||

| 1 1/2" | 00000000 | 00000 |

| 2", 2 1/2" | 00000000 | 00000 |

| 3 1/4" | 00000000 | 00000 |

| 4" | 00000000 | 00000 |

Front/Rear Flanges | ||

| 1 1/2" | 000000000 | 000000 |

| 2" | 000000000 | 000000 |

| 2 1/2" | 000000000 | 000000 |

| 3 1/4" | 000000000 | 000000 |

| 4" | 000000000 | 000000 |

Clevis Brackets with Clevis Pin | ||

| 1 1/2" | 00000000 | 000000 |

| 2" | 00000000 | 000000 |

| 2 1/2" | 00000000 | 000000 |

| 3 1/4" | 00000000 | 000000 |

| 4" | 00000000 | 000000 |

Corrosion-Resistant Hydraulic Cylinders

Made of 303 stainless steel, these hydraulic cylinders move heavy loads without corroding in wet areas. Four tie rods protect the barrel from impact and keep the end caps secure. These cylinders are double acting, meaning they pull loads as well as push them—and do so with nearly as much force. The mounting footprint meets NFPA and JIC (Joint Industrial Congress) compatibility standards.

Because they have a magnetic piston, these cylinders can be used with tie rod-mount proximity switches (not included) to indicate piston position. All have an adjustable cushion that cuts down on shock and noise.

O'all | Mounting Hole | Inlet/Outlet Connection— NPTF | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Stroke Lg. | Max. Push Force, lbs. | Max. Pull Force, lbs. | Retracted Lg. | Extended Lg. | Rod Thread Size | Wd. | Ht. | Ctr.-to-Ctr. | Dia. | Pipe Size | Dash Size | Body Material | Max. Pressure, psi | Air Cushion Type | Each | |

NFPA and JIC Heavy Duty Mounting Pattern | ||||||||||||||||

1 1/2" Bore Dia. | ||||||||||||||||

| 1" | 700 | 580 | 6 13/16" | 7 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 0000000 |

| 2" | 700 | 580 | 7 13/16" | 9 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 4" | 700 | 580 | 9 13/16" | 13 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 6" | 700 | 580 | 11 13/16" | 17 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 8" | 700 | 580 | 13 13/16" | 21 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 12" | 700 | 580 | 17 13/16" | 29 13/16" | 7/16"-20 | 3 3/8" | 2" | 2 3/4" | 5/16" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

2" Bore Dia. | ||||||||||||||||

| 1" | 1,250 | 1,130 | 6 15/16" | 7 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 2" | 1,250 | 1,130 | 7 15/16" | 9 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 4" | 1,250 | 1,130 | 9 15/16" | 13 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 6" | 1,250 | 1,130 | 11 15/16" | 17 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 8" | 1,250 | 1,130 | 13 15/16" | 21 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 12" | 1,250 | 1,130 | 17 15/16" | 29 15/16" | 7/16"-20 | 4 1/8" | 2 1/2" | 3 3/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

2 1/2" Bore Dia. | ||||||||||||||||

| 1" | 1,960 | 1,840 | 7 1/16" | 8 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 000000 |

| 2" | 1,960 | 1,840 | 8 1/16" | 10 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 4" | 1,960 | 1,840 | 10 1/16" | 14 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 6" | 1,960 | 1,840 | 12 1/16" | 18 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 8" | 1,960 | 1,840 | 14 1/16" | 22 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| 12" | 1,960 | 1,840 | 18 1/16" | 30 1/16" | 7/16"-20 | 4 5/8" | 3" | 3 7/8" | 3/8" | 3/8 | 06 | 303 Stainless Steel | 400 | Adjustable Cushion | 0000000 | 00000000 |

| For Bore Dia. | Material | Mounting Fasteners Included | Each | |

Clevis Rod Ends | ||||

|---|---|---|---|---|

| 1 1/2" | Stainless Steel | __ | 0000000 | 0000000 |

| 2", 2 1/2" | Stainless Steel | __ | 0000000 | 000000 |

Pivot Brackets | ||||

| 1 1/2" | Stainless Steel | No | 0000000 | 000000 |

| 2", 2 1/2" | Stainless Steel | No | 0000000 | 000000 |

Clevis Pins | ||||

| 1 1/2" | 17-4 Stainless Steel | __ | 0000000 | 000000 |

| 2", 2 1/2" | 17-4 Stainless Steel | __ | 0000000 | 000000 |

Clevis Brackets with Clevis Pin | ||||

| 1 1/2" | Stainless Steel | No | 0000000 | 000000 |

| 2", 2 1/2" | Stainless Steel | No | 0000000 | 00000000 |