Filter by

Torch Body Type

Head Movement

Nozzle Material

DFARS Specialty Metals

Export Control Classification Number (ECCN)

REACH

RoHS

TIG Welding Type

TIG Torch Bodies

Replace worn torch bodies on your TIG torch.

Rigid-Neck Torch Bodies

Gas Valve Not Included |

Water Cooled—Water-cooled torch bodies cool more efficiently than air-cooled torch bodies, which keeps your torch from overheating, even when welding continuously and for long periods of time.

Gas Valve Not Included—Use torch bodies without a gas valve with a machine that has a built-in gas valve.

Flexible-Neck Torch Bodies

|

Gas Valve Not Included |

Gas Valve Included |

Torch bodies with a flexible neck have a copper coil that bends, so you can weld in hard-to-reach areas. However, the copper coil will loosen over time.

Water Cooled—Water-cooled torch bodies cool more efficiently than air-cooled torch bodies, which keeps your torch from overheating, even when welding continuously and for long periods of time.

Gas Valve Not Included—Use torch bodies without a gas valve with a machine that has a built-in gas valve.

Gas Valve Included—Torch bodies with a gas valve allow you to control the gas flow at your torch instead of at the machine.

Ball-Joint Torch Bodies with Interchangeable Head

Gas Valve Not Included |

Gas Valve Included |

Ball-joint torch bodies have similar flexibility to those with a flexible neck for welding in hard-to-reach areas. Because the ball joint does not loosen with time, they last longer than torch bodies with a flexible neck. They have interchangeable heads, so you can quickly swap nozzle configurations for different welding jobs.

Gas Valve Not Included—Use torch bodies without a gas valve with a machine that has a built-in gas valve.

Gas Valve Included—Torch bodies with a gas valve allow you to control the gas flow at your torch instead of at the machine.

TIG Torch Bodies for Pipe Welding

For welding pipe, these torch bodies have a head that either pivots or rotates.

Rigid-Neck Torch Bodies

Gas Valve Included |

Rigid-neck torch bodies have a pivoting head and are often used on large-diameter pipe and tubing. They withstand longer welding cycles than torch bodies with a rotating head. To prevent binding or twisting on the cable, their body rocks back and forth on the cable.

Gas Valve Included—Torch bodies with a gas valve let you control the flow of gas at your torch instead of at your welder.

Flexible-Neck Torch Bodies

Gas Valve Included |

Flexible-neck torch bodies bend to weld in hard-to-reach areas. They also have a pivoting head for use on large-diameter pipe and tubing. They work for longer welding cycles than torches with a rotating head. Their torch body rocks back and forth on the cable, preventing it from binding or twisting.

Gas Valve Included—Torch bodies with a gas valve let you control the flow of gas at your torch instead of at your welder.

Rotating-Head Torch Bodies with Interchangeable Head

|

Gas Valve Not Included |

|

Gas Valve Included |

Torch bodies with an interchangeable head let you quickly swap out heads with different nozzle configurations to tackle different welding jobs. Their head rotates 360° to account for different welding positions, so they’re often used to weld small-diameter pipe.

Gas Valve Not Included—Torch bodies without a gas valve require a welder with a built-in gas valve.

Gas Valve Included—Torch bodies with a gas valve let you control the flow of gas at your torch instead of at your welder.

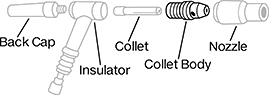

TIG Torch Collet Bodies

|

Attach TIG torch nozzles to TIG torches with these collet bodies. Holes in the collet body route shielding gas to the nozzle to protect your weld from oxidation and pitting. Use them with a split or wedge collet to hold a tungsten electrode. All collet bodies require a TIG torch insulator.

For Aluminum Oxide Ceramic and Silicon Nitride Ceramic Nozzles

|

Collet bodies for aluminum oxide ceramic and silicon nitride ceramic nozzles have threads for connecting to nozzles. Use an adapter ring (sold separately) to connect quartz glass nozzles to these collet bodies.

TIG Torch Collet Bodies | TIG Torch Adapter Rings for Quartz Glass Nozzles | ||||||

|---|---|---|---|---|---|---|---|

For Narrow Gas Coverage | |||||||

For Torch Series No. | Choose an Electrode Diameter (Industry Number) | Each | Nozzle Connection | Each | |||

| 9, 20, 25 | 0.020" (13N25) , 0.040" (13N26) , 0.063" (13N27) , 0.094" (13N28) , 0.125" (13N29) | 77425A85 | 00000 | Threaded × Push On | 90567A120 | 00000 | |

| 17, 18, 26 | 0.040" (10N30) , 0.063" (10N31) , 0.094" (10N32) , 0.125" (10N28) , 0.156" (406488) | 77425A86 | 0000 | Threaded × Push On | 90567A110 | 0000 | |

For Borosilicate Glass Nozzles

|

Collet bodies for borosilicate glass nozzles have a silicone O-ring. Press the nozzle onto the collet body, and the O-ring holds it in place.