How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Strainers and Selecting Screen Size

More

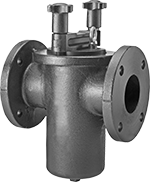

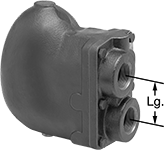

Low-Pressure Iron Y-Strainers

A rugged iron body provides excellent strength and durability. Strainers prevent damage to valves, pumps, nozzles, and other sensitive equipment by catching debris in your pipeline. They are designed for low-pressure applications. Strainers are for use in noncorrosive environments. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Strainers with flanged pipe connections allow for easy access to your pipeline; bolt them to a flange with the same pipe size.

Strainers | Replacement Screens | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Lg. | Ht. | Plug Pipe Size | Screen Material | Choose a Screen Mesh Size | Choose a Screen Opening Size | Each | Each | ||

With Mesh Screen | ||||||||||

| 1/4 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | 20 | __ | 0000000 | 000000 | 0000000 | 000000 |

| 3/8 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 0000000 | 00000 |

| 1/2 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 00000000 | 00000 |

| 3/4 | 4" | 4 1/2" | 1/2 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 0000000 | 00000 |

| 1 | 4 7/8" | 5 3/8" | 3/4 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 00000000 | 00000 |

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 0000000 | 00000 |

| 1 1/2 | 5 3/4" | 6 3/16" | 1 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 0000000 | 00000 |

| 2 | 7 1/4" | 8" | 1 1/4 | 304 Stainless Steel | 20 | __ | 0000000 | 00000 | 00000000 | 00000 |

With Mesh and Perforated Screen | ||||||||||

| 1/4 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 3/8 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1/2 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 3/4 | 4" | 4 1/2" | 1/2 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 | 4 7/8" | 5 3/8" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 1/2 | 5 3/4" | 6 3/16" | 1 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 2 | 7 1/4" | 8" | 1 1/4 | 304 Stainless Steel | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 2 1/2 | 8 7/8" | 9 3/4" | 1 1/4 | 304 Stainless Steel | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 2 1/2 | 8 7/8" | 9 3/4" | 1 1/4 | 304 Stainless Steel | 20 | __ | 0000000 | 000000 | 0000000 | 000000 |

| 3 | 10" | 10 15/16" | 1 1/2 | 304 Stainless Steel | __ | 0000000 | 000000 | 0000000 | 000000 | |

| 3 | 10" | 10 15/16" | 1 1/2 | 304 Stainless Steel | 20 | __ | 0000000 | 000000 | 0000000 | 000000 |

With Perforated Screen | ||||||||||

| 1/2 | 3" | 3 1/2" | 3/8 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 3/4 | 4" | 4 1/2" | 1/2 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 | 4 7/8" | 5 3/8" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 1/4 | 5 1/8" | 5 15/16" | 3/4 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 1 1/2 | 5 3/4" | 6 3/16" | 1 | 304 Stainless Steel | __ | 0000000 | 00000 | 0000000 | 00000 | |

| 2 | 7 1/4" | 8" | 1 1/4 | 304 Stainless Steel | __ | 0000000 | 000000 | 0000000 | 00000 | |

| 2 1/2 | 8 7/8" | 9 3/4" | 1 1/4 | 304 Stainless Steel | __ | 0000000 | 000000 | 0000000 | 00000 | |

Strainers | Replacement Screens | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Ht. | Plug Pipe Size | Screen Material | Choose a Screen Opening Size | Each | Each | ||

With Perforated Screen | |||||||||||

| 2 | 6" | 125 | 7 7/8" | 8 1/16" | 1/2 | 304 Stainless Steel | 0000000 | 0000000 | 0000000 | 000000 | |

| 2 1/2 | 7" | 125 | 10" | 9 5/8" | 1 | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 00000 | |

| 3 | 7 1/2" | 125 | 10 1/8" | 10 5/16" | 1 | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 000000 | |

| 4 | 9" | 125 | 12 1/8" | 12 9/16" | 1 1/2 | 304 Stainless Steel | 0000000 | 000000 | 0000000 | 000000 | |

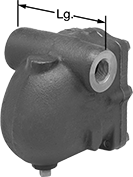

Medium-Pressure Iron and Steel Y-Strainers

- Max. Pressure for Water, Oil, and Inert Gas:

Iron: 600 psi @ 100° F

Steel: 700 psi @ 100° F

Max. Pressure for Steam:

Iron: 450 psi @ 650° F

Steel: 300 psi @ 400° F - Temp. Range:

Iron: -20° to 650° F

Steel: -20° to 400° F

Made of rugged iron or steel, these strainers provide excellent strength and durability. Install them prior to valves, pumps, and nozzles to protect sensitive equipment from damage caused by debris. They are designed for medium-pressure applications. Strainers are for use in noncorrosive environments. They have a threaded drain with a plug that provides access to the screen without disconnecting your line.

Strainers | Replacement Screens | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Plug Pipe Size | Material | Screen Material | Screen OD | Screen Lg. | Choose a Screen Opening Size | Each | Each | ||

With Perforated Screen | |||||||||||||

| 1/2 | NPT | 3" | 3 1/2" | 3/8 | Iron | 304 Stainless Steel | 23/32" | 2 7/16" | 000000 | 000000 | 0000000 | 000000 | |

| 3/4 | NPT | 4" | 4 1/2" | 1/2 | Iron | 304 Stainless Steel | 7/8" | 3 1/8" | 000000 | 00000 | 0000000 | 00000 | |

| 1 | NPT | 4 7/8" | 5 3/8" | 3/4 | Iron | 304 Stainless Steel | 1 1/4" | 3 7/8" | 000000 | 000000 | 0000000 | 00000 | |

| 1 1/2 | NPT | 5 3/4" | 6 3/16" | 1 | Iron | 304 Stainless Steel | 1 3/4" | 4 1/4" | 000000 | 000000 | 0000000 | 00000 | |

| 2 | NPT | 7 1/4" | 8" | 1 1/4 | Iron | 304 Stainless Steel | 2 1/4" | 5 1/8" | 000000 | 000000 | 0000000 | 00000 | |

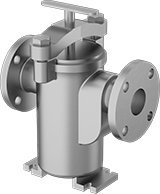

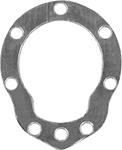

Iron Basket Strainers

- For Use With:

Threaded: Water, Oil, and Diesel Fuel

Flanged: Water and Oil

Flanged with Mounting Brackets: Water, Oil, and Diesel Fuel - Max. Pressure: 200 psi @ 100° F

- Temp. Range:

Threaded: 20° to 200° F

Flanged: -20° to 150° F

Flanged with Mounting Brackets: 20° to 200° F

Commonly used in high-flow industrial processes, these basket strainers hold more debris than all of our other strainers. Install them prior to valves, pumps, and nozzles in your pipeline to protect sensitive equipment. Strainers should be used in noncorrosive environments. They have a threaded drain with a plug for easy cleaning.

Strainers with flanged pipe connections allow for easy access to your pipeline; bolt them to a flange with the same pipe size.

Strainers with mounting brackets mount to the floor for stability.

To Order: For strainers with a choice between basket mesh size and opening size, select a mesh size for a mesh basket or an opening size for a perforated basket.

Strainers | Replacement Baskets | Replacement Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Ht. | Gasket Material | Basket Material | Choose a Basket Mesh Size | Choose a Basket Opening Size | Each | Each | Each | |||

| 3/8 | NPT | 4" | 6 5/8" | Buna-N Rubber | 316 Stainless Steel | 000000 | 0000000 | 0000000 | 0000000 | 00000000 | 000000 | ||

| 1/2 | NPT | 4" | 6 5/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3/4 | NPT | 5 3/8" | 8 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 | NPT | 5 3/8" | 8 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 1/4 | NPT | 6 3/4" | 9 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 1 1/2 | NPT | 7 3/8" | 11" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 2 | NPT | 8 3/4" | 13 3/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 2 1/2 | NPT | 10 1/2" | 14 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3 | NPT | 11 5/8" | 17 3/4" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

Strainers | Replacement Baskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Ht. | Gasket Material | Basket Material | Specifications Met | Basket Opening Size | Each | Each | ||

| 2 | 6" | 125 | 8" | 11 7/8" | Buna-N Rubber | 304 Stainless Steel | ASTM A126 Class B | 1/8" | 00000000 | 0000000 | 00000000 | 0000000 |

| 3 | 7 1/2" | 125 | 9 3/4" | 14 7/8" | Buna-N Rubber | 304 Stainless Steel | ASTM A126 Class B | 1/8" | 00000000 | 000000 | 00000000 | 000000 |

| 4 | 9" | 125 | 11 1/2" | 16 1/4" | Buna-N Rubber | 304 Stainless Steel | ASTM A126 Class B | 1/8" | 00000000 | 000000 | 00000000 | 000000 |

Strainers | Replacement Baskets | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Ht. | Gasket Material | Basket Material | Choose a Basket Mesh Size | Choose a Basket Opening Size | Each | Each | Each | |||

| 2 | 6" | 125 | 10 1/2" | 13 3/4" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 000000000 | 0000000 | 0000000 | 00000000 | 000000 | ||

| 2 1/2 | 7" | 125 | 11 5/8" | 15 5/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 3 | 7 1/2" | 125 | 13 1/8" | 18" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | ||

| 4 | 9" | 125 | 16 3/4" | 19 7/8" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 00000000 | 00000000 | 00000 | ||

| 6 | 11" | 125 | 19 5/8" | 28 1/2" | Buna-N Rubber | 316 Stainless Steel | 00000000 | 00000000 | 0000000 | 00000000 | 00000000 | 00000 | ||

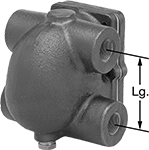

Easy-Swap Iron Basket Strainers

- Max. Pressure for Water, Oil, and Diesel Fuel: 150 psi @ 70° F

- Temp. Range: 20° to 150° F

No need to shut down your operation to service your strainer—these have two baskets so you can divert flow to one basket while you work on the other. Turn the valve handle to direct flow. Commonly used in high-flow industrial processes, basket strainers hold more debris all of our other strainers. Install them in your pipeline to prevent particles from damaging sensitive equipment. Strainers should be used in noncorrosive environments. They have a threaded drain with a plug for easy cleaning. Mounting brackets on the bottom allow you to bolt strainers to the floor for stability.

Strainers with flanged pipe connections allow for easy access to your pipeline; bolt them to a flange with the same pipe size.

Strainers | Replacement Baskets | Replacement Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Lg. | Wd. | Ht. | Gasket Material | Basket Material | Choose a Basket Opening Size | Each | Each | Each | |||

| 3/4 | NPT | 5 1/2" | 10 1/2" | 10 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 0000000 | 00000000 | 000000 | |

| 1 | NPT | 5 1/2" | 10 1/2" | 10 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 1 1/4 | NPT | 8 3/4" | 13 1/4" | 12 3/4" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 1 1/2 | NPT | 7 1/2" | 13 1/4" | 12 3/4" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 2 | NPT | 10" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 2 1/2 | NPT | 10" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

Strainers | Replacement Baskets | Replacement Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | For ANSI Flange Class | Lg. | Wd. | Ht. | Gasket Material | Basket Material | Choose a Basket Opening Size | Each | Each | Each | |||

| 2 | 6" | 125 | 10 5/8" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 000000000 | 0000000 | 0000000 | 00000000 | 000000 | |

| 2 1/2 | 7" | 125 | 10 3/4" | 17 3/8" | 15 1/2" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 3 | 7 1/2" | 125 | 13 1/2" | 22 3/4" | 18" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

| 4 | 9" | 125 | 16" | 24 3/4" | 21 5/8" | Buna-N Rubber | 316 Stainless Steel | 0000000 | 00000000 | 0000000 | 000000 | 00000000 | 00000 | |

Energy-Saving Iron Steam Traps

Also known as thermostatic steam traps, these vent cool air and condensate to increase energy efficiency in your steam lines. The vent on these steam traps is normally open, allowing condensate and air to flow out. The vent closes immediately when steam enters to prevent energy loss. Use them with heat exchangers, air-heating coils, and drip stations in steam lines.

Style A has an inlet and an outlet on each side to connect inline or parallel steam and condensate lines.

Style B has an inlet and an outlet on the same side to connect parallel steam and condensate lines.

Style C has an inlet and outlet on opposite sides to connect inline steam and condensate lines.

| Style | Pipe Size | Thread Type | Gender | Pipeline Orientation | Max. Pressure, psi | Max. Temp., °F | Condensate Capacity, lbs./hr. | Lg. | Ht. | Includes | Each | |

Iron with Stainless Steel Float | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 3/4 | NPT | Female | Horizontal | 15 | 250° | 1,075 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 0000000 |

| A | 3/4 | NPT | Female | Horizontal | 30 | 270° | 1,370 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 3/4 | NPT | Female | Horizontal | 75 | 320° | 1,450 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 3/4 | NPT | Female | Horizontal | 125 | 350° | 1,190 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 15 | 250° | 1,075 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 30 | 270° | 1,370 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 75 | 320° | 1,450 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 | NPT | Female | Horizontal | 125 | 350° | 1,190 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 1/4 | NPT | Female | Horizontal | 15 | 250° | 2,340 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| A | 1 1/4 | NPT | Female | Horizontal | 30 | 270° | 2,000 | 3 5/16" | 5 3/4" | Two Plugs for Unused Ports | 0000000 | 000000 |

| B | 1 1/4 | NPT | Female | Horizontal | 75 | 320° | 5,400 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/4 | NPT | Female | Horizontal | 125 | 350° | 4,500 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 15 | 250° | 7,600 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 30 | 270° | 7,000 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 75 | 320° | 5,400 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 1 1/2 | NPT | Female | Horizontal | 125 | 350° | 4,500 | 3" | 8 3/8" | __ | 0000000 | 000000 |

| B | 2 | NPT | Female | Horizontal | 15 | 250° | 10,900 | 4 15/16" | 9 1/8" | __ | 0000000 | 000000 |

| B | 2 | NPT | Female | Horizontal | 30 | 270° | 10,000 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |

| B | 2 | NPT | Female | Horizontal | 75 | 320° | 7,700 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |

| B | 2 | NPT | Female | Horizontal | 125 | 350° | 6,600 | 4 15/16" | 9 1/8" | __ | 0000000 | 00000000 |

| C | 1/2 | NPT | Female | Horizontal | 15 | 450° | 1,075 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1/2 | NPT | Female | Horizontal | 30 | 450° | 1,370 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1/2 | NPT | Female | Horizontal | 75 | 450° | 1,450 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1/2 | NPT | Female | Horizontal | 125 | 450° | 1,190 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1/2 | NPT | Female | Horizontal | 200 | 450° | 985 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 3/4 | NPT | Female | Horizontal | 15 | 450° | 1,075 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 3/4 | NPT | Female | Horizontal | 30 | 450° | 1,370 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 3/4 | NPT | Female | Horizontal | 75 | 450° | 1,450 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 3/4 | NPT | Female | Horizontal | 125 | 450° | 1,190 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 3/4 | NPT | Female | Horizontal | 200 | 450° | 985 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1 | NPT | Female | Horizontal | 15 | 450° | 1,075 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1 | NPT | Female | Horizontal | 30 | 450° | 1,370 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1 | NPT | Female | Horizontal | 75 | 450° | 1,450 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1 | NPT | Female | Horizontal | 125 | 450° | 1,190 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

| C | 1 | NPT | Female | Horizontal | 200 | 450° | 985 | 4 13/16" | 5 13/16" | __ | 00000000 | 000000 |

High-Flow Iron Steam Traps

Also known as inverted-bucket steam traps, these provide near-continuous discharge to accommodate high condensate levels. They are normally open to release condensate from steam lines and close immediately when steam enters to prevent energy loss.

Steam Traps | Replacement Cover Gaskets | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Pipeline Orientation | Max. Pressure, psi | Max. Temp., °F | Condensate Capacity, lbs./hr. | Lg. | Ht. | Each | Pkg. Qty. | Pkg. | ||

Iron | |||||||||||||

| 1/2 | NPT | Female | Horizontal | 15 | 450° | 1,040 | 5" | 6 3/8" | 0000000 | 0000000 | 3 | 0000000 | 0000000 |

| 1/2 | NPT | Female | Horizontal | 30 | 450° | 1,000 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1/2 | NPT | Female | Horizontal | 75 | 450° | 965 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1/2 | NPT | Female | Horizontal | 125 | 450° | 920 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1/2 | NPT | Female | Horizontal | 250 | 450° | 720 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 15 | 450° | 1,040 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 15 | 450° | 3,220 | 6 5/8" | 7 5/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 30 | 450° | 1,000 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 30 | 450° | 3,220 | 6 5/8" | 7 5/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 75 | 450° | 965 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 75 | 450° | 2,550 | 6 5/8" | 7 5/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 125 | 450° | 920 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 125 | 450° | 2,240 | 6 5/8" | 7 5/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 250 | 450° | 720 | 5" | 6 3/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 3/4 | NPT | Female | Horizontal | 250 | 450° | 2,300 | 6 5/8" | 7 5/8" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 | NPT | Female | Horizontal | 15 | 450° | 3,900 | 8" | 9 1/4" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 | NPT | Female | Horizontal | 30 | 450° | 4,120 | 8" | 9 1/4" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 | NPT | Female | Horizontal | 75 | 450° | 3,960 | 8" | 9 1/4" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 | NPT | Female | Horizontal | 125 | 450° | 4,100 | 8" | 9 1/4" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 | NPT | Female | Horizontal | 250 | 450° | 3,630 | 8" | 9 1/4" | 0000000 | 000000 | 3 | 0000000 | 000000 |

| 1 1/4 | NPT | Female | Horizontal | 125 | 450° | 8,540 | 9 3/8" | 13" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

| 1 1/4 | NPT | Female | Horizontal | 250 | 450° | 6,040 | 9 3/8" | 13" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

| 2 | NPT | Female | Horizontal | 30 | 450° | 18,500 | 11 1/4" | 17" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

| 2 | NPT | Female | Horizontal | 75 | 450° | 19,200 | 11 1/4" | 17" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

| 2 | NPT | Female | Horizontal | 125 | 450° | 20,000 | 11 1/4" | 17" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

| 2 | NPT | Female | Horizontal | 250 | 450° | 19,400 | 11 1/4" | 17" | 0000000 | 00000000 | 3 | 0000000 | 000000 |

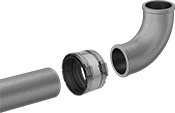

Drain, Waste, and Vent Iron Pipe Fittings

Use these fittings in gravity-flow applications both above and below ground. They are also known as no-hub pipe fittings and soil pipe fittings. To connect, place the end of the fitting against your pipe or another fitting and connect with a low-pressure clamp-on connector (sold separately). The clamp-on connector is also known as a no-hub coupling. Fittings are for use in noncorrosive environments.

The 270° bend connectors are also known as P-traps.

- For Use With: Water

- Temperature Range: 0° to 180° F

- Specifications Met: ASTM A666, ASTM C564

- For Pipe Material: Aluminum, Iron, Steel, Stainless Steel, PVC Plastic

- For Use With: Water

- Temperature Range: 0° to 180° F

- Specifications Met: ASTM A666, ASTM C564

- For Pipe Material: Aluminum, Iron, Steel, Stainless Steel, PVC Plastic

- For Tube Material: Copper

- For Use With: Water

- Temperature Range: 0° to 180° F

- Specifications Met: ASTM A666, ASTM C564

- For Pipe Material: Aluminum, Iron, Steel, Stainless Steel, PVC Plastic