How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Air Preparation

More

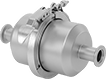

Stainless Steel Quick-Clamp T-Strainers

- Max. Pressure for Beverage, Dairy, Food, Pharmaceuticals, and Water: 150 psi @ 72° F

- Temp. Range: -50° to 275° F

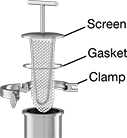

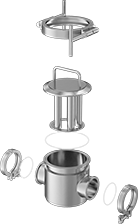

Add these inline T-strainers to your sanitary process line to trap solid particles during clean-in-place (CIP) cycles. They have quick-clamp sanitary tube connections, also known as tri-clamp connections, for use in dairy, food, and other process lines that require frequent cleaning and disassembly. As the high-pressure cleaning fluid flows through your line, the strainer's screen catches particles larger than 1/8" to prevent damage to pumps, valves, and other downstream components. And because the total open area of the screen is larger than the area of the tube itself, the screen will not restrict flow.

Strainers come with a gasket and clamp to secure the screen inside the strainer. Gaskets and clamps for connecting the strainer to your line are sold separately. A handle lets you remove the screen to clean it between runs.

Strainers | Replacement Clamps | Replacement Screens | Replacement EPDM Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Lg. | Ht. | Screen Material | Screen Opening Size | Screen Lg. | Each | Each | Each | Each | ||||

316 Stainless Steel | ||||||||||||||

| 1 1/2" | 1.984" | 5 1/2" | 5 7/8" | 316 Stainless Steel | 1/8" | 3 1/2" | 0000000 | 0000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 00000 |

| 2" | 2.516" | 7" | 6 7/8" | 316 Stainless Steel | 1/8" | 4 1/2" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 2 1/2" | 3.047" | 7" | 7 3/16" | 316 Stainless Steel | 1/8" | 4 3/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 3" | 3.579" | 7 1/2" | 7 11/16" | 316 Stainless Steel | 1/8" | 5 1/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

Sanitary Magnetic Strainers

- For Use With: Beverage, Dairy, Food, Salt Solutions, Sodium Nitrate, Water

- Max. Pressure: 150 psi @ 225° F

- Temp. Range: -20° to 225° F

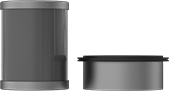

Draw metal shavings and other contaminants out of your sanitary liquid line with these strainers. As liquid swirls through the strainer cavity, magnets sealed inside capture any metal bits. Remaining impurities are separated out with gravity and trapped in a collection sump. Empty the strainers by removing the lid and scooping up the collected particles at the bottom of the enclosure. These strainers have quick-clamp connections, so they’re good for frequent deep cleans and line changes. Also known as tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for quick removal and assembly.

These strainers are 316 stainless steel, which won’t corrode from frequent washdowns with harsh cleaners. The continuous weld seams and polished surfaces are free of pits and crevices where bacteria could grow, making them easy to sanitize. Rated for high temperatures, you can keep these strainers on your line during a heated clean-in-place (CIP) process. All strainers and their included gasket are FDA compliant, meaning they are safe for food contact.

Filters that are USDA certified meet the highest standards of sanitary design.

| Pipe Size | Max. Magnetic Pull, lbs. | Lg. | Ht. | Magnet Material | Gasket Material | Specifications Met | Each | |

316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 | 14.25 | 9 3/4" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 |

| 2 | 14.25 | 9 3/4" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

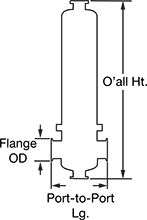

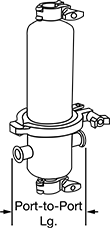

Sanitary Metal Filter Housings with Cartridge

for Food and Beverage Steam Lines

Remove contaminants, moisture, and other particles from steam that will touch food and for final filtering in pharmaceutical, biotech, and electronics applications. The cartridge in these housings filters out 98% of particles as small as 1 micron and 100% of particles as small as 2 microns. That’s why they meet 3-A’s accepted practice for creating culinary-grade steam, which is often used in steam-in-place (SIP) cycles to sanitize equipment, and for applications such as blanching. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

All are made of 316 stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them, and they withstand steam. These housings are designed to sanitary standards; they’re 3-A certified 10-04 and meet ASME BPE. They have rounded edges and highly polished interior and exterior surfaces, minimizing the spots where bacteria could grow. For the same reason, they don’t have horizontal ledges—liquid completely drains off.

They connect to your line with two quick-clamp fittings that are easy to take apart for cleaning and line reconfiguration. Each fitting is tightly sealed with an EPDM gasket, which has excellent resistance to steam.

Cartridges can be cleaned and reused, but after six cleanings you should replace them to maintain high performance.

Filter Housings with Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Removes Particle Size Down To, microns | Replacement Cartridges | |||||||||||||

| For Tube OD | Flange OD | Steam Capacity | 98% Efficiency | 100% Efficiency | Max. Pressure, psi | Max. Temp., °F | Cartridge Useful Life | Port-to-Port Length | Overall Height | Specifications Met | Each | Each | ||

Quick Clamp Tube Vent and Drain | ||||||||||||||

316 Stainless Steel Housing and Cartridge | ||||||||||||||

| 1/2" | 0.984" | 100 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 4 23/32" | 9" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 | 0000000 | 0000000 |

| 1" | 1.984" | 400 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 14 1/2" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 000000 |

| 2" | 1.984" | 800 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 19 3/4" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 00000000 |

Sanitary Metal Filter Housings

Along with a cartridge, these housings are used in liquid processing lines to filter contaminants and minimize bacteria growth in food and pharmaceutical plants, as well as other sanitary environments. Made of 316 stainless steel, they won’t corrode from frequent washdowns with harsh cleaners. With a self-draining design, rounded edges, and highly polished surfaces, they leave no space for liquids to linger or bacteria to grow. These housings connect to process lines with sanitary quick-clamp fittings that allow for fast disassembly and cleaning. An EPDM rubber gasket maintains a tight seal and resists water, detergents, chemicals, and steam. The gasket is FDA compliant for direct contact with food. Housings are 3-A certified for sanitary design standards and comply with FDA pharmaceutical equipment design standards.

Cartridges (sold separately) are pleated, creating a large surface area for trapping debris. They have one open end with an EPDM rubber O-ring and locking tabs—the O-ring creates a tight seal to ensure that liquids pass through the cartridge for filtration, while the locking tabs help align with cartridges for a secure fit. Cartridges are FDA compliant for direct contact with food.

Cartridges with a polypropylene filter are often used as pre-filters in liquid processing lines, capturing larger particles to prevent clogging.

Cartridges with a PES filter remove extremely small particles, so they’re commonly used as final filters in high-purity applications. They’re also known as absolute-rated cartridges.

For Cartridge | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Ht. | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Port-to-Port Length | Overall Height | Specifications Met | Each | |

| 1" | 1.984" | 21.9" | 2.2" | O-Ring End Caps | 1 | 15 | 150 | 300 | 9 13/16" | 32 1/4" | 3-A Certified 10-04, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 0000000 | 000000000 |

Removes Particle Size Down To, microns | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | 80% Efficiency | 90% Efficiency | 98% Efficiency | 99.9% Efficiency | Max. Pressure, psi | Max. Temp., °F | Specifications Met | Each | |

Polypropylene Plastic | |||||||||

| 21.9" | 3 | 5 | 10 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 |

| 21.9" | 10 | 20 | 30 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

PES Plastic | |||||||||

| 21.9" | __ | __ | __ | 0.2 | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2240, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

High-Vacuum Inline Filters

Capture oil, oil vapor, and other contaminants from your pump to prevent them from spreading into your high-vacuum system with these filters. When it's time to replace the filter element, you don't need tools to access it; undo the quick-release clamp to open the filter body. Filters have a drain port to remove collected oil.

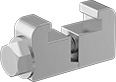

Filters with quick-clamp connections (also known as KF, NW, and QF fittings) require a quick clamp and a ring (both sold separately) for each connection.

Filters with claw-clamp connections (also known as ISO-K fittings) will connect to larger components than filters with quick-clamp connections. Use four claw clamps and a ring (all sold separately) to secure each connection. Double-claw clamps attach to the grooves on the fittings. Single-claw clamps have a clamp on one end and an exposed bolt on the other. Thread the bolt-end directly into the body of pumps, valves, or other high-vacuum components.

Inline Filters | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Replacement Elements | ||||||||||||

| High-Vacuum Flange Size | Flange OD | For Tube OD | Max. Flow Rate | High Vacuum Connection Type | Max. Vacuum | Max. Temp., °F | Lg. | Dia. | Removes Particle Size Down To, microns | Each | Each | ||

Quick-Clamp Connection—304 Stainless Steel Housing | |||||||||||||

| 16 | 1.18" | 3/4" | 50 scfm @ 14.7 psi | ISO-KF | 10 -8 torr @ 72° F | 300° | 8 3/4" | 5 1/4" | 0.1 | 0000000 | 0000000 | 0000000 | 000000 |

| 25 | 1.57" | 1" | 50 scfm @ 14.7 psi | ISO-KF | 10 -8 torr @ 72° F | 300° | 8 3/4" | 5 1/4" | 0.1 | 0000000 | 000000 | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | 100 scfm @ 14.7 psi | ISO-KF | 10 -8 torr @ 72° F | 300° | 11 1/4" | 7 3/8" | 0.1 | 0000000 | 000000 | 0000000 | 000000 |

| 50 | 2.95" | 2" | 200 scfm @ 14.7 psi | ISO-KF | 10 -8 torr @ 72° F | 300° | 11 1/4" | 7 3/8" | 0.1 | 0000000 | 00000000 | 0000000 | 000000 |

Claw-Clamp Connection—304 Stainless Steel Housing | |||||||||||||

| 63 | 3.74" | 2 1/2" | 300 scfm @ 14.7 psi | ISO-K | 10 -8 torr @ 72° F | 300° | 18 1/8" | 9" | 0.1 | 0000000 | 00000000 | 0000000 | 000000 |

| For High-Vacuum Flange Size | For Flange OD | For Tube OD | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

Quick-Clamp Connection—Clamp with Wing Nut | |||||||

|---|---|---|---|---|---|---|---|

| 10; 16 | 1.18" | 1/2"; 3/4" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 25 | 1.57" | 1" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 50 | 2.95" | 2" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

Claw-Clamp Connection—Double-Claw Clamp with Bolt | |||||||

| 63; 80; 100 | 3.74", 4.33", 5.12" | 2 1/2"; 3"; 4" | ISO-K | Aluminum | 10 -8 torr @ 72° F | 0000000 | 0000 |

Claw-Clamp Connection—Single-Claw Clamp with Bolt | |||||||

| 63; 80; 100 | 3.74", 4.33", 5.12" | 2 1/2"; 3"; 4" | ISO-K | Aluminum | 10 -8 torr @ 72° F | 0000000 | 0000 |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For High-Vacuum Flange Size | For Flange OD | For Tube OD | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Max. Temp., °F | Each | |

Quick-Clamp Connection | |||||||||

| 16 | 1.18" | 3/4" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 00000000 | 00000 |

| 25 | 1.57" | 1" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

| 50 | 2.95" | 2" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

Claw-Clamp Connection | |||||||||

| 63 | 3.74" | 2 1/2" | __ | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 400° | 0000000 | 00000 |

High-Vacuum Air-Intake Filters

Install these filters between your high-vacuum chamber and the inlet of your pump to remove dust, water vapor, and other contaminants from the system and protect the pump. Commonly used in vacuum-furnace and coating applications, they have a polyester filter element that traps particles as small as 5 microns. All filters have been helium-leak tested to ensure quality. When the filter element becomes clogged, you can replace it.

Quick-clamp connections are also known as KF, QF, and NW connections; they require a ring and quick clamp (sold separately) to complete the connection.

Air-Intake Filters | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

O'all | Element | Replacement Elements | |||||||||||||

| High-Vacuum Flange Size | Flange OD | For Tube OD | Max. Flow Rate | Max. Vacuum | Temp. Range, °F | Ht. | Dia. | Removes Particle Size Down To, microns | Filter Efficiency | Ht. | OD | Each | Each | ||

Quick-Clamp (ISO-KF) Connection—Polyester Plastic Element | |||||||||||||||

| 16 | 1.18" | 3/4" | 23 scfm @ 14.7 psi | 10 -8 torr @ 72° F | -15° to 220° | 3 7/8" | 3 3/4" | 5 | 99% | 2 11/16" | 2 1/2" | 0000000 | 0000000 | 0000000 | 000000 |

| 25 | 1.57" | 1" | 35 scfm @ 14.7 psi | 10 -8 torr @ 72° F | -15° to 220° | 4 3/8" | 5 3/4" | 5 | 99% | 2 3/4" | 3 7/8" | 0000000 | 000000 | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | 80 scfm @ 14.7 psi | 10 -8 torr @ 72° F | -15° to 220° | 7 3/16" | 7 3/8" | 5 | 99% | 4 3/4" | 5" | 0000000 | 000000 | 0000000 | 00000 |

| 50 | 2.95" | 2" | 175 scfm @ 14.7 psi | 10 -8 torr @ 72° F | -15° to 220° | 11 11/16" | 8 3/4" | 5 | 99% | 8 3/4" | 5 7/8" | 0000000 | 000000 | 0000000 | 00000 |

Material | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For High-Vacuum Flange Size | For Flange OD | For Tube OD | High Vacuum Connection Type | O-Ring | Inner Ring | Max. Vacuum | Max. Temp., °F | Each | |

Quick-Clamp Connection | |||||||||

| 16 | 1.18" | 3/4" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 00000000 | 00000 |

| 25 | 1.57" | 1" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

| 50 | 2.95" | 2" | ISO-KF | Viton® Fluoroelastomer Rubber | 304 Stainless Steel | 10 -8 torr @ 72° F | 300° | 0000000 | 00000 |

| For High-Vacuum Flange Size | For Flange OD | For Tube OD | High Vacuum Connection Type | Material | Max. Vacuum | Each | |

Quick-Clamp Connection—Clamp with Wing Nut | |||||||

|---|---|---|---|---|---|---|---|

| 10, 16 | 1.18" | 1/2", 3/4" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 00000000 | 00000 |

| 25 | 1.57" | 1" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 40 | 2.16" | 1 1/2" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| 50 | 2.95" | 2" | ISO-KF | Aluminum | 10 -8 torr @ 72° F | 0000000 | 00000 |

| Each | ||

| 0000000 | 00000 |

High-Vacuum Oil-Mist-Eliminating Exhaust Filters

Clamp these exhaust filters onto oil-sealed, high-vacuum pumps to remove oil, smoke, and other contaminants and keep workplace air clean. Once captured, the oil returns to the pump to be reused. Instead of a threaded connection, these filters have a quick-clamp high-vacuum fitting, which is commonly found on high-vacuum pumps. Quick-clamp high-vacuum fittings are also known as KF, QF, and NW fittings; they require a ring and clamp (sold separately) to complete the connection.

O'all | Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High-Vacuum Flange Size | Flange OD | For Tube OD | Max. Flow Rate | High Vacuum Connection Type | Max. Vacuum | Max. Temp., °F | Ht. | Dia. | Removes Particle Size Down To, microns | Filter Efficiency | Ht. | ID | OD | Material | Each | |

Nickel-Plated Steel Housing | ||||||||||||||||

| 16 | 1.18" | 3/4" | 4.5 scfm @ 14.7 psi | ISO-KF | Not Rated | 180° | 4" | 2 1/2" | 0.3 | 99.9% | 3" | 1 1/4" | 2 1/4" | Fiberglass | 0000000 | 0000000 |

| 25 | 1.57" | 1" | 4.5 scfm @ 14.7 psi | ISO-KF | Not Rated | 180° | 4" | 2 1/2" | 0.3 | 99.9% | 3" | 1 1/4" | 2 1/4" | Fiberglass | 0000000 | 000000 |

| 25 | 1.57" | 1" | 24 scfm @ 14.7 psi | ISO-KF | Not Rated | 180° | 8 5/16" | 5" | 0.3 | 99.9% | 6" | 3" | 4" | Fiberglass | 0000000 | 000000 |

| 40 | 2.16" | 1 1/2" | 55 scfm @ 14.7 psi | ISO-KF | Not Rated | 180° | 8 3/16" | 10 1/4" | 0.3 | 99.9% | 6" | 8" | 9" | Fiberglass | 0000000 | 000000 |

Odor-Absorbing High-Vacuum Oil-Mist-Eliminating Exhaust Filters

To keep airborne oil and odor out of your work environment, connect these filters to your high-vacuum oil pump. They purify pump exhaust in two stages: a fiberglass layer captures oil and collects it into a drain, and an active carbon layer removes any odor-causing oil or chemical vapors. Attach the quick-clamp fitting on the filter inlet to your high-vacuum pump. Use a ring and clamp (sold separately) to complete the connection.

O'all | Element | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High-Vacuum Flange Size | Flange OD | For Tube OD | Max. Flow Rate | High Vacuum Connection Type | Max. Vacuum | Max. Temp., °F | Ht. | Dia. | Removes Particle Size Down To, microns | Filter Efficiency | Ht. | OD | Material | Each | |

Epoxy-Coated Steel Housing | |||||||||||||||

| 16 | 1.18" | 3/4" | 11 scfm @ 14.7 psi | ISO-KF | Not Rated | 110° | 8 3/8" | 4 1/8" | 0.3 | 99.9% | 3 3/4" | 3" | Fiberglass and Carbon | 0000000 | 0000000 |

| 25 | 1.57" | 1" | 11 scfm @ 14.7 psi | ISO-KF | Not Rated | 110° | 8 3/8" | 4 1/8" | 0.3 | 99.9% | 3 3/4" | 3" | Fiberglass and Carbon | 0000000 | 000000 |

| Ht. | OD | Removes Particle Size Down To, microns | Filter Efficiency | Reinforcement Type | Each | |

Fiberglass and Carbon | ||||||

|---|---|---|---|---|---|---|

| 3 3/4" | 3" | 0.3 | 99.9% | Epoxy-Coated Steel Wire | 0000000 | 0000000 |

Exhaust Filters/Mufflers for Dry High-Vacuum Pumps

Purify exhaust fumes while silencing the noise from your oil-free high-vacuum pumps. With quick-clamp (KF) connections, these filters/mufflers connect to exhaust ports with a clamp and ring (sold separately). Mount them vertically or horizontally. All are carbon steel with a powder-coated finish for corrosion resistance.

O'all | Element | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| High-Vacuum Flange Size | Flange OD | For Tube OD | Max. Flow Rate | High Vacuum Connection Type | Max. Vacuum | Temp. Range, °F | Ht. | Dia. | Removes Particle Size Down To, microns | Noise Reduction Rating, dBA | Filter Efficiency | Ht. | OD | Material | Each | |

Powder-Coated Steel Housing with Zinc-Plated Steel Fittings | ||||||||||||||||

| 16 | 1.18" | 3/4" | 9 scfm @ 14.7 psi | ISO-KF | Not Rated | -15° to 220° | 3 3/4" | 3 1/4" | 25 | 10-15 | 99% | 1 3/8" | 3" | Polyester Plastic | 0000000 | 0000000 |

| 25 | 1.57" | 1" | 11 scfm @ 14.7 psi | ISO-KF | Not Rated | -15° to 220° | 3 3/4" | 3 1/4" | 25 | 10-15 | 99% | 1 3/8" | 3" | Polyester Plastic | 0000000 | 000000 |

| 25 | 1.57" | 1" | 24 scfm @ 14.7 psi | ISO-KF | Not Rated | -15° to 220° | 4 1/2" | 4 1/8" | 25 | 10-15 | 99% | 1 3/8" | 4" | Polyester Plastic | 0000000 | 000000 |

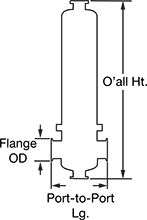

Sanitary Compressed Air Filters for Oil, Particle, and Bacteria Removal

Remove bacteria, viruses, moisture, and other particles from compressed air and gases used in food, pharmaceutical, biotech, and electronics applications. These air filters catch 99.99% of particles as small as 0.003 microns. That’s why they meet 3-A’s accepted practice for creating sterile air, which is used in applications such as tank ventilation, pharmaceutical packaging, and beer fermentation. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

Designed for sanitary areas, these air filters are 3-A certified 10-04 and meet ASME BPE. Their housing and filter element are stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them. They can also be sterilized in an autoclave or using steam in sterilize-in-place (SIP) procedures. To make sure water and cleaning liquids drain off, these air filters don’t have any horizontal ledges. The smooth, polished sides and rounded edges minimize spots where bacteria could grow.

These air filters have two quick-clamp fittings, which are easy to remove for cleaning and access to your line. Each fitting has an EPDM gasket for a tight seal and excellent resistance to steam.

To maintain high performance, replace the filter element every 150 cycles.

| For Tube OD | Flange OD | Max. Flow Rate | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Filter Service Indicator Included | Overall Ht. | Port-to-Port Lg. | Gasket Material | Features | Specifications Met | Each | |

Quick Clamp Tube Vent and Drain | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

316 Stainless Steel Housing—Opaque with Automatic Drain | |||||||||||||

| 1/2" | 0.984" | 36 scfm @ 100 psi | 230 | 390° | 0.003 | No | 9" | 4 23/32" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 |

| 3/4" | 0.984" | 108 scfm @ 100 psi | 230 | 390° | 0.003 | No | 11 1/8" | 4 23/32" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

| 1" | 1.984" | 216 scfm @ 100 psi | 230 | 390° | 0.003 | No | 14 1/2" | 6 3/8" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

| 2" | 2.516" | 432 scfm @ 100 psi | 230 | 390° | 0.003 | No | 19 3/4" | 6 3/8" | EPDM Rubber | Drain with Cap, Gasket, and Clamp Vent with Cap, Gasket, and Clamp | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 |

| For Tube OD | Material | Max. Temp., °F | Removes Particle Size Down To, microns | End Cap Material | O-Ring Material | Each | |

| 1/2" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 0000000 |

| 3/4" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 000000 |

| 1" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 000000 |

| 2" | 304 Stainless Steel | 390° | 0.003 | 304 Stainless Steel | Silicone Rubber | 0000000 | 00000000 |