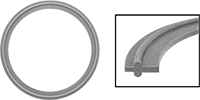

Ultra-Chemical-Resistant Metal-Detectable

PTFE Gaskets for Quick-Clamp Tube Fittings

If a piece wears off, fragments as small as 1 mm can be picked up by a metal-detection system to prevent contamination of your process line. These gaskets are made from a blend of PTFE and stainless steel, which is chemically inert (except to molten alkali metal and elemental fluorine). The construction also allows them to maintain their strength in steam and hot oil applications.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 1/2" | 0.38" | 0.86" | 0.178" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 3/4" | 0.62" | 0.86" | 0.178" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 0000 |

| 1" | 0.9" | 1.98" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 1 1/2" | 1.4" | 1.98" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 2" | 1.9" | 2.52" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 2 1/2" | 2.4" | 3.05" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 3" | 2.9" | 3.58" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 4" | 3.87" | 4.68" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 6" | 5.82" | 6.51" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 8" | 7.77" | 8.57" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 00000 |

| 10" | 9.7" | 10.56" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 000000 |

| 12" | 11.73" | 12.56" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 000000 |

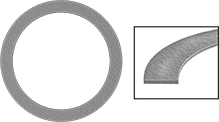

Ultra-Chemical-Resistant Metal-Detectable PTFE Gaskets

for Extra-Support Quick-Clamp Sanitary Tube Fittings

Made from a blend of PTFE and 316 stainless steel, these gaskets hold up to the harsh chemicals, high pressures, and high temperatures used in sanitary processes. They’ll set off metal detectors if they fall into your line, so you can prevent contaminated material from leaving your facility. This helps you comply with Hazard Analysis and Critical Control Point (HACCP) programs. Use them with extra-support quick-clamp sanitary tube fittings (also known as I-line fittings) to create a tight, leak-proof seal.

These gaskets are more durable and last longer than standard PTFE seals. To protect against leaks, they won’t warp or deform, even in steam or hot oil, and they won’t degrade from harsh cleaners. They’re also chemically inert, so they won’t contaminate your line by absorbing and leaching substances (except when used with molten alkali metal or elemental fluorine). They’re often used in applications where purity is essential, such as in food, pharmaceutical, or biotech facilities.

The interior of these gaskets is extremely smooth, so they’re easy to clean and bacteria has nowhere to grow. They’re Animal Derived Ingredient (ADI) free, meaning they are made without animal products, and they’re FDA compliant for direct contact with food. Made to the highest standards of sanitary design, these gaskets are 3-A and USP VI certified. They’re also tested to USP 87 standards, which are created by the United States Pharmacopoeia (USP) for safety in biological applications.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 1" | 0.91" | 1.27" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 000000 |

| 1 1/2" | 1.41" | 1.76" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2" | 1.88" | 2.26" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2 1/2" | 2.40" | 2.77" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 3" | 2.88" | 3.32" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 4" | 3.89" | 4.30" | 0.072" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

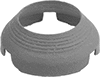

Gaskets for 37° Flared Tube Fittings

Prevent leaks from temperature fluctuations and vibration that can loosen 37° flared tube fittings. In general, you should match your gasket material to your fitting material. But, if you have a brass fitting, you can use a copper gasket.

Gaskets without a coating are best for fittings that are exposed to harsh chemicals, such as antifreeze, which can dissolve the threadlocker coating.

Threadlocker-coated gaskets offer a more secure hold than uncoated gaskets, so they’re best for areas with high vibration.

For technical drawings and 3-D models, click on a part number.

Thread | Temperature, °F | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Dash Size | Size | Type | Thickness | Maximum Pressure, psi | Min. | Max. | Each | |

316 Stainless Steel | |||||||||

| 3/16" | 03 | 3/8"-16 | UN/UNF (JIC) | 0.145" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

| 1/4" | 04 | 7/16"-20 | UN/UNF (JIC) | 0.183" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 5/16" | 05 | 1/2"-20 | UN/UNF (JIC) | 0.188" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 3/8" | 06 | 9/16"-18 | UN/UNF (JIC) | 0.205" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 1/2" | 08 | 3/4"-16 | UN/UNF (JIC) | 0.26" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 5/8" | 10 | 7/8"-14 | UN/UNF (JIC) | 0.268" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 3/4" | 12 | 1 1/16"-12 | UN/UNF (JIC) | 0.274" | 20,000 | Not Rated | 2500° | 00000000 | 0000 |

| 7/8" | 14 | 1 3/16"-12 | UN/UNF (JIC) | 0.28" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

| 1" | 16 | 1 5/16"-12 | UN/UNF (JIC) | 0.285" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

| 1 1/2" | 24 | 1 7/8"-16 | UN/UNF (JIC) | 0.351" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

| 2" | 32 | 2 1/2"-12 | UN/UNF (JIC) | 0.43" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

Threadlocker-Coated 316 Stainless Steel—Black | |||||||||

| 3/16" | 03 | 3/8"-16 | UN/UNF (JIC) | 0.145" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 1/4" | 04 | 7/16"-20 | UN/UNF (JIC) | 0.183" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 5/16" | 05 | 1/2"-20 | UN/UNF (JIC) | 0.188" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 3/8" | 06 | 9/16"-18 | UN/UNF (JIC) | 0.205" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 1/2" | 08 | 3/4"-16 | UN/UNF (JIC) | 0.26" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 5/8" | 10 | 7/8"-14 | UN/UNF (JIC) | 0.268" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 3/4" | 12 | 1 1/16"-12 | UN/UNF (JIC) | 0.274" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 7/8" | 14 | 1 3/16"-12 | UN/UNF (JIC) | 0.28" | 20,000 | -40° | 1200° | 00000000 | 00000 |

| 1" | 16 | 1 5/16"-12 | UN/UNF (JIC) | 0.285" | 20,000 | -40° | 1200° | 00000000 | 00000 |

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 1200° | 00000000 | 0000 |

| 1 1/2" | 24 | 1 7/8"-16 | UN/UNF (JIC) | 0.351" | 20,000 | -40° | 1200° | 00000000 | 00000 |

| 2" | 32 | 2 1/2"-12 | UN/UNF (JIC) | 0.43" | 20,000 | -40° | 1200° | 00000000 | 00000 |

Threadlocker-Coated 316 Stainless Steel—Green | |||||||||

| 3/16" | 03 | 3/8"-16 | UN/UNF (JIC) | 0.145" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 1/4" | 04 | 7/16"-20 | UN/UNF (JIC) | 0.183" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 5/16" | 05 | 1/2"-20 | UN/UNF (JIC) | 0.188" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 3/8" | 06 | 9/16"-18 | UN/UNF (JIC) | 0.205" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 1/2" | 08 | 3/4"-16 | UN/UNF (JIC) | 0.26" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 5/8" | 10 | 7/8"-14 | UN/UNF (JIC) | 0.268" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 3/4" | 12 | 1 1/16"-12 | UN/UNF (JIC) | 0.274" | 20,000 | -40° | 300° | 00000000 | 0000 |

| 7/8" | 14 | 1 3/16"-12 | UN/UNF (JIC) | 0.28" | 20,000 | -40° | 300° | 00000000 | 00000 |

| 1" | 16 | 1 5/16"-12 | UN/UNF (JIC) | 0.285" | 20,000 | -40° | 300° | 00000000 | 00000 |

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 300° | 00000000 | 00000 |

| 1 1/2" | 24 | 1 7/8"-16 | UN/UNF (JIC) | 0.351" | 20,000 | -40° | 300° | 00000000 | 00000 |

| 2" | 32 | 2 1/2"-12 | UN/UNF (JIC) | 0.43" | 20,000 | -40° | 300° | 00000000 | 00000 |

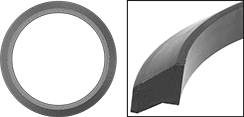

Ultra-Chemical-Resistant Metal-Detectable

PTFE Gaskets for Gasket Tube Fittings

Made from a blend of PTFE and 316 stainless steel, these gaskets stand up to the harsh chemicals and high pressures and temperatures used in sanitary processes. They’ll set off metal detectors if any part of them falls into your line, so you can stop contaminated material from leaving your facility. This helps you comply with Hazard Analysis and Critical Control Point (HACCP) programs. Use these gaskets with high-polish gasket fittings (also called bevel seat fittings) for a more secure seal than quick-clamp sanitary tube fittings.

These gaskets are more durable and last longer than standard PTFE seals. Hot oil, steam, and harsh cleaners won’t warp or deform them, preventing leaks. They’re also chemically inert, so they won’t contaminate your line by absorbing and leaching substances, unless you use molten alkali metal or elemental fluorine. Use them where purity is necessary, such as in food, pharmaceutical, or biotech facilities.

With an extremely smooth interior, these gaskets are easy to clean and leave minimal places for bacteria to grow. To minimize safety risks, they are Animal Derived Ingredient (ADI) free, meaning they’re made without animal products, and are FDA compliant for direct contact with food. Meeting the highest sanitary design standards, these gaskets are 3-A and USP VI certified. They’re also tested to USP 87 standards, which are created by the United States Pharmacopoeia (USP) for safety in biological applications.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 1" | 0.900" | 1.325" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 000000 |

| 1 1/2" | 1 3/8" | 1 7/8" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2" | 1.850" | 2 3/8" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 2 1/2" | 2.340" | 2.950" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 3" | 2 7/8" | 3.475" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 4" | 3.700" | 4 1/2" | 0.32" | -350° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |