How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Backflow-Prevention Valves

More

About On/Off Valves

More

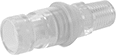

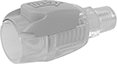

High-Flow Quick-Disconnect Tube Couplings for Chemicals

- For Use With: Acetic Acid (20%), Ammonia, Carbon Dioxide, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydraulic Fluid (Petroleum Based), Hydrochloric Acid, Hydrogen Peroxide (30%), Kerosene, Methanol, Nitric Acid (20%), Potassium Hydroxide, Sodium Carbonate, Sodium Hydroxide (20%), Sulfuric Acid (75%), Synthetic Oil

- Temperature Range: 32° to 250° F

- Tubing: Use with soft or firm (Durometer 55A-95A) nylon plastic, polyethylene plastic, polypropylene plastic, polyurethane rubber, PVC plastic or TPE plastic

A spring-free flow path allows more chemicals to pass through these tube couplings at lower line pressures than other quick-disconnect couplings. This reduces turbulence, foaming, bubbles, and blockage. They have a shut-off valve that stops the flow when the coupling is disconnected, so chemicals won’t leak from your line. Unlike couplings with a button release, these have a safety slide to reduce accidental separation from bumps or drops. They are often used in laboratories, pharmaceutical facilities, and other sterile environments.

Made of PVDF, also known as Kynar, these couplings have excellent chemical and UV resistance at ambient and elevated temperatures. They also resist abrasion, impact, flames, and corrosion. Compared to other quick-disconnect couplings for chemicals, these couplings can withstand higher temperatures—all the way up to 250° F.

When you insert the plug into the socket, it’ll connect with a click. To disconnect, slide the latch on the socket and remove the plug.

Note: For a complete coupling, order a plug and a socket with the same coupling size.

For technical drawings and 3-D models, click on a part number.

They have a single barb that grips onto tubing or hose and provides a smooth clamping surface for extra-tight connections that minimize leaks.

They have a single barb that grips onto tubing or hose and provides a smooth clamping surface for extra-tight connections that minimize leaks.

With Shut-Off | |||||||

|---|---|---|---|---|---|---|---|

| Pipe Size | Coupling Size | For Plug OD | Material | Color | Max. Pressure | Each | |

NPT Threads | |||||||

| 1/8 | 7/8 | 9/16" | PVDF Plastic | White | 90 psi @ 72° F | 0000000 | 000000 |

| 1/4 | 1 | 11/16" | PVDF Plastic | White | 90 psi @ 72° F | 0000000 | 00000 |

| 3/8 | 1 | 11/16" | PVDF Plastic | White | 90 psi @ 72° F | 0000000 | 00000 |

| 1/2 | 1 3/8 | 1" | PVDF Plastic | White | 90 psi @ 72° F | 0000000 | 00000 |

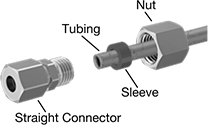

Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Compressed Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Helium, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Instead of a metal sleeve (ferrule), these fittings have a rubber sleeve that cushions tubing and absorbs vibration to maintain a tight seal, even when connected to large pumps. However, rubber sleeves can’t withstand temperatures as high as metal ones. To create the strong seal, tighten the included nut. These fittings are made of 316 stainless steel, so they have excellent corrosion resistance. They’re also known as flareless fittings. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

BSPP and metric male threads have a gasket to prevent leaks.

Male Threads with

Gasket and Washer

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Maximum Pressure | Each | |

NPT Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 0000000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 00000 |

| 8 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | 3/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 15 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 18 | 2 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

BSPP Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

Metric Threads | |||||||||

| 8 | 1 | __ | M12 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | __ | M14 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 6 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 000000 |

| 8 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 12 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 15 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 18 | 2 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

Nuts for Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Diesel Fuel, Compressed Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Helium, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Pair these nuts with vibration-resistant compression sleeves and fittings for a strong seal on stainless steel tubing. Made of 316 stainless steel, they have excellent corrosion resistance. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Sleeve Material | Maximum Pressure | Each | |

| 6 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

| 8 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 12 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 15 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 18 | 2 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

Check Valves with Barbed Fittings for Harsh Chemicals

Prevent backflow in chemical tubing lines. These valves have barbed fittings that grip onto tubing, providing a secure hold. The plastic body and fluoroelastomer seal provide excellent chemical resistance. Valves open to allow flow in one direction and close when flow stops or reverses.

Polypropylene valves are more corrosion resistant than nylon valves.

Nylon valves are more impact resistant than polypropylene valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Acetone, Air, Argon, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Krypton, Mineral Spirits, Neon, Nitrogen, Oil, Propane, Salt Water, Soap Solutions, Toluene, Water, Xenon, Xylene

- Ball Material: 316 Stainless Steel

- Spring Material: 302 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

- For Use With: Acetone, Air, Argon, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Krypton, Mineral Spirits, Neon, Nitrogen, Oil, Propane, Salt Water, Soap Solutions, Toluene, Water, Xenon, Xylene

- Ball Material: 316 Stainless Steel

- Spring Material: 302 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

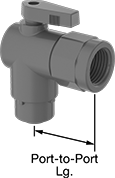

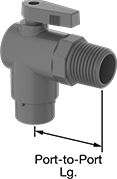

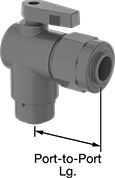

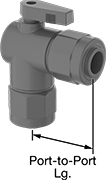

On/Off Valves with Push-to-Connect Fittings for Chemicals

Push to Connect ×

Push to Connect

Insert tubing into the fittings on these valves—no heat, solder, or flux required. To withstand aggressive and corrosive solutions, they have a chemical-resistant fluoroelastomer seal and a plastic body.

Full-port valves do not restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With:

Connector: Air, Argon, Carbon Dioxide, Citric Acid, Deionized Water, Ethylene Glycol, Helium, Isopropyl Alcohol, Krypton, Natural Gas, Neon, Nitrogen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water, Xenon

Adapter: Air, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Fuel Oil, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Nitric Acid, Nitrogen, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water, Xylene - Ball Material: PVDF Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: Fluoroelastomer Rubber

| Pipe Size | For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Port-to-Port Lg. | Each | |

Straight Adapter, Push to Connect × Female NPT Threaded | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 000000 |

| 1/4 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 1/4 | 1/2" | 7 | 125 psi @ 140° F | 35° to 140° | Full | 2 15/16" | __ | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 3/8 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 3/8 | 1/2" | 9.1 | 125 psi @ 140° F | 35° to 140° | Full | 2 15/16" | __ | 000000000 | 00000 |

| 1/2 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/16" | __ | 000000000 | 00000 |

| 1/2 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/16" | __ | 000000000 | 00000 |

| 1/2 | 1/2" | 6.8 | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/8" | __ | 000000000 | 00000 |

Straight Adapter, Push to Connect × Male NPT Threaded | |||||||||

| 1/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/2" | __ | 000000000 | 00000 |

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/4 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/2" | __ | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 3/16" | __ | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 3/16" | __ | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/2" | __ | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/16" | __ | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/16" | __ | 000000000 | 00000 |

| 1/2 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/2" | __ | 000000000 | 00000 |

Straight Adapter, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 2 3/16" | __ | 000000000 | 00000 |

| __ | 1/4" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| __ | 3/8" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Female NPT Threaded | |||||||||

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

| 1/2 | 1/2" | 2.8 | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Male NPT Threaded | |||||||||

| 1/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 1/4" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| __ | 3/8" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

90° Elbow Connector, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 3/8" × 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 1/2" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

- Valve Type: Ball

- For Use With: Air, Citric Acid, Deionized Water, Ethanol, Ethylene Glycol, Helium, Kerosene, Mineral Spirits, Nitrogen, Salt Water, Soap Solutions, Water, Xylene

- Ball Material: Nylon Plastic

- Seal Material: Fluoroelastomer Rubber

- Seat Material: Fluoroelastomer Rubber

| Pipe Size | For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Port-to-Port Lg. | Each | |

Straight Adapter, Push to Connect × Female NPT Threaded | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 000000 |

| 1/4 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 1/4 | 1/2" | 7 | 125 psi @ 140° F | 35° to 140° | Full | 2 15/16" | __ | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 3/8 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Full | 2 5/8" | __ | 000000000 | 00000 |

| 3/8 | 1/2" | 9.1 | 125 psi @ 140° F | 35° to 140° | Full | 2 15/16" | __ | 000000000 | 00000 |

| 1/2 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/16" | __ | 000000000 | 00000 |

| 1/2 | 3/8" | 1.9 | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/16" | __ | 000000000 | 00000 |

| 1/2 | 1/2" | 6.8 | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/8" | __ | 000000000 | 00000 |

Straight Adapter, Push to Connect × Male NPT Threaded | |||||||||

| 1/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 7/16" | __ | 000000000 | 00000 |

| 1/4 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 7/16" | __ | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 3/16" | __ | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 3/16" | __ | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/2" | __ | 000000000 | 00000 |

| 1/2 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/16" | __ | 000000000 | 00000 |

| 1/2 | 3/8" | 2.9 | 125 psi @ 140° F | 35° to 140° | Standard | 3 3/16" | __ | 000000000 | 00000 |

| 1/2 | 1/2" | 6.8 | 125 psi @ 140° F | 35° to 140° | Standard | 3 1/2" | __ | 000000000 | 00000 |

Straight Adapter, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 2 13/16" | __ | 000000000 | 00000 |

| __ | 1/4" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

| __ | 3/8" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | 3 1/8" | __ | 000000000 | 00000 |

Straight Connector, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | 2 13/16" | __ | 000000000 | 00000 |

| __ | 3/8" × 3/8" | 2.9 | 125 psi @ 140° F | 35° to 140° | Full | 2 13/16" | __ | 000000000 | 00000 |

| __ | 1/2" × 1/2" | 6.8 | 125 psi @ 140° F | 35° to 140° | Full | 3 7/16" | __ | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Female NPT Threaded | |||||||||

| 1/4 | 1/4" | 0.7 | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 1/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

| 1/2 | 1/2" | 2.8 | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 5/8" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Male NPT Threaded | |||||||||

| 1/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 1/4 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| 3/8 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 3/8 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 3/8 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

| 1/2 | 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Standard | __ | 1 3/4" | 000000000 | 00000 |

90° Elbow Adapter, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 1/4" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

| __ | 3/8" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

90° Elbow Connector, Push to Connect × Push to Connect | |||||||||

| __ | 1/4" × 1/4" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 3/8" × 3/8" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 3/8" | 000000000 | 00000 |

| __ | 1/2" × 1/2" | Not Rated | 125 psi @ 140° F | 35° to 140° | Full | __ | 1 11/16" | 000000000 | 00000 |

On/Off Valves with Barbed Fittings for Chemicals

Barbs grip onto tubing, providing a secure hold. To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a plastic body and a chemical-resistant seal.

PVDF valves have excellent chemical resistance. They withstand a variety of acids, solvents, and other harsh substances.

Four-arm handles have a mounting tab to securely align the valve with connecting lines. They’re ideal for systems prone to vibration that can cause movement and leaks.

Full-port valves do not restrict flow.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions

- Ball Material: PVDF Plastic

- Seal Material: PVDF Plastic

- Seat Material: PVDF Plastic

| For Tube ID | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Features | Each | |

Standard Barbed × Standard Barbed | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | 15 psi @ 65° F | 35° to 100° | Full | 2 1/8" | With Mounting Tab | 00000000 | 000000 |

| 5/16" | 15 psi @ 65° F | 35° to 100° | Full | 2 1/8" | With Mounting Tab | 00000000 | 00000 |

| 3/8" | 15 psi @ 65° F | 35° to 100° | Full | 2 3/4" | With Mounting Tab | 00000000 | 00000 |

| 7/16" | 15 psi @ 65° F | 35° to 100° | Full | 2 3/4" | With Mounting Tab | 00000000 | 00000 |

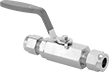

On/Off Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Ball

- For Use With: Acetone, Air, Ammonia, Carbon Dioxide, Diesel Fuel, Gasoline, Kerosene

- Ball Material: Monel

- Seal Material: PTFE Plastic

- Seat Material: PTFE Plastic

- Specifications Met: ASME B16.34, ASME B31.3

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. These valves have a PTFE seal and a corrosion-resistant Monel ball and body that can stand up to aggressive and corrosive chemicals such as acetone. All are standard port, so they slightly restrict flow. A red handle makes them easy to identify.

For technical drawings and 3-D models, click on a part number.

On/Off Valves with Yor-Lok Fittings for Fuel

- Valve Type: Ball

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Kerosene

- Seal Material: PTFE Plastic

- Specifications Met: ASME B16.34

For extra gripping power and a strong seal, the Yor-Lok fittings on these valves have two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. Designed for transferring diesel fuel, fuel oil, gasoline, and kerosene, these valves have a 316 stainless steel body for excellent corrosion resistance. All are standard port, so they slightly restrict flow.