About Precision Flow-Adjustment Valves

More

About Backflow-Prevention Valves

More

Check Valves with Barbed Fittings for Harsh Chemicals

Prevent backflow in chemical tubing lines. These valves have barbed fittings that grip onto tubing, providing a secure hold. The plastic body and fluoroelastomer seal provide excellent chemical resistance. Valves open to allow flow in one direction and close when flow stops or reverses.

Polypropylene valves are more corrosion resistant than nylon valves.

Nylon valves are more impact resistant than polypropylene valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Acetone, Air, Argon, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Krypton, Mineral Spirits, Neon, Nitrogen, Oil, Propane, Salt Water, Soap Solutions, Toluene, Water, Xenon, Xylene

- Ball Material: 316 Stainless Steel

- Spring Material: 302 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

- For Use With: Acetone, Air, Argon, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Kerosene, Krypton, Mineral Spirits, Neon, Nitrogen, Oil, Propane, Salt Water, Soap Solutions, Toluene, Water, Xenon, Xylene

- Ball Material: 316 Stainless Steel

- Spring Material: 302 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

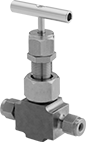

Precision Flow-Adjustment Valves with Yor-Lok Fittings for Chemicals

- Valve Type: Needle

- For Use With: Oil, Acetone, Air, Ammonia, Argon, Butane, Carbon Dioxide, Deionized Water, Diesel Fuel, Ethanol, Gasoline, Helium, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Natural Gas, Neon, Nitrogen, Oxygen, Propane, Soap Solutions, Sodium Hydroxide, Toluene, Xenon, Xylene

- Seal Material: PTFE Plastic

- Seat Material: 316 Stainless Steel

- Packing Material: PTFE Plastic

- Needle Material: 316 Stainless Steel

For extra gripping power and a strong seal, these valves have Yor-Lok fittings with two sleeves that bite into tubing as you tighten the nut. All are compatible with Swagelok®, Let-Lok, and Parker A-Lok fittings. The 316 stainless steel body, seal and needle, and the PTFE seat and packing can withstand aggressive and corrosive solutions in chemical-processing applications. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to mount these valves in instrument panels. All have a nut that can be tightened to compress the packing if it leaks. Valves have bubble-tight soft seats that provide a tight seal when the valve is completely closed.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Panel Cutout Dia. | End-to-End Lg. | Each | |

316 Stainless Steel Body | |||||||

|---|---|---|---|---|---|---|---|

Yor Lok × Yor Lok | |||||||

| 1/4" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 0000000 |

| 3/8" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 2 7/8" | 0000000 | 000000 |

| 1/2" | 0.56 | 7000 psi @ 400° F | -20° to 400° | 0.87" | 3 1/8" | 0000000 | 000000 |

Precision Flow-Adjustment Valves with Barbed Fittings for Chemicals

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Xenon, Xylene

- Seal Material: PTFE Plastic

- Packing Material: PTFE Plastic

- Needle Material: PVDF Plastic

Barbs grip onto tubing, providing a secure hold. To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a PTFE seal and a PVDF body. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to install these valves in instrument panels. They have a nut that can be tightened to compress the packing if it leaks.

For technical drawings and 3-D models, click on a part number.

| For Tube ID | For Tube OD | Flow Coefficient (Cv) | Max. Pressure | Max. Temperature, °F | Panel Cutout Dia. | End-to-End Lg. | Each | |

Black PVDF Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Barbed × Barbed | ||||||||

| 1/4" | 3/8" | 0.3 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 000000 |

| 3/8" | 1/2" | 0.3 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 00000 |

| 1/2" | 5/8" | 0.4 | 125 psi @ 140° F | 140° | 7/8" | 3 5/16" | 0000000 | 00000 |

Precision Flow-Adjustment Valves with Push-to-Connect Fittings for Chemicals

- Valve Type: Needle

- For Use With: Water, Oil, Air, Argon, Butane, Carbon Dioxide, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Methanol, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Xenon, Xylene

- Seal Material: Fluoroelastomer Rubber

- Packing Material: PTFE Plastic

- Needle Material: PVDF Plastic

Insert tubing into the fittings on these valves—no heat, solder, or flux required. With a fluoroelastomer seal and a PVDF body, they can withstand aggressive and corrosive solutions in chemical-processing applications. Turn the handle to adjust flow in small increments for metering, sampling, and other applications requiring fine flow control. Threads and a hex nut below the handle allow you to install these valves in instrument panels. They have a nut that can be tightened to compress the packing if it leaks.