How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

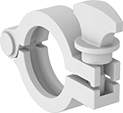

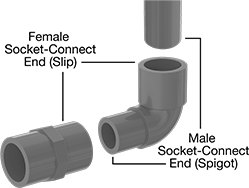

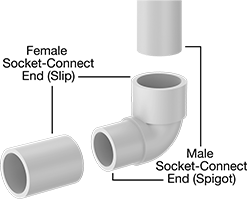

Socket-Connect Fittings for Plastic Tubing—Air and Water

- Temperature Range: 0° to 140° F

- Tubing: Use with PVC plastic

Made of soft PVC, these fittings flex to withstand high-vibration applications. Use them in place of rigid fittings to create a more flexible system. To connect, slide fittings onto tubing and secure with a clamp.

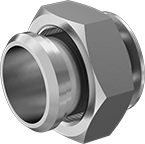

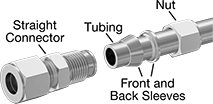

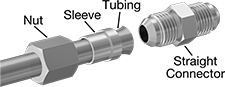

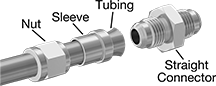

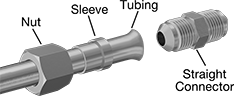

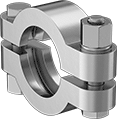

Yor-Lok Fittings for Stainless Steel Tubing

(SAE Straight) Male

Threads with Gasket

A nut with two sleeves (ferrules) gives these fittings extra gripping power. The sleeves bite into tubing as you tighten the nut, creating a strong seal. Also known as instrumentation fittings, they are made to tight tolerances for use in high-precision applications. They are compatible with Swagelok®, Let-Lok, and A-Lok fittings.

316 stainless steel fittings have excellent corrosion resistance.

BSPP and UN/UNF (SAE Straight) male threads have a gasket to protect against leaks. UN/UNF (SAE Straight) threads are also known as O-ring boss threads.

(SAE Straight) Male

Threads with Gasket

- For Use With:

Inch:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water - Tubing:

Inch:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT, BSPT, and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Thread Size | Material | Gasket Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||||

| 1 1/4" | 0.083" | 1 1/4 | __ | 316 Stainless Steel | __ | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

UN/UNF (SAE Straight) Threads | |||||||||

| 1 1/4" | 0.083" | __ | 1 5/8"-12 | 316 Stainless Steel | Fluoroelastomer Rubber | 1,900 psi @ 72° F | -15° to 400° | 00000000 | 000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing:

Inch:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

Metric:

NPT Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 1 1/4" | 0.083" | 1 1/4 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

- For Use With:

NPT and BSPT Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

BSPP Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Mineral Oil, Water

UN/UNF (SAE Straight) Threads: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil - Tubing:

NPT and UN/UNF (SAE Straight) Threads: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

BSPP and BSPT Threads: Use with seamless 304 or 316 stainless steel that meets ASTM A269

For Tube | |||||||

|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

| 1 1/4" | 0.083" | 1 1/4 | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Material | Max. Pressure | Temp. Range, °F | Each | |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 0000000 |

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Tubing: Use with welded or seamless 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

Caps for tubing have a nut and a sleeve so you can close off the end of your tubing in place of a fitting. Caps for fittings replace the nut and sleeve of an existing fitting.

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Temp. Range, °F | Each | |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | -420° to 1200° | 00000000 | 000000 |

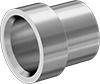

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 1 1/4" | 0.083" | 316 Stainless Steel | 35/64" | 1 | 13/64" | 1 | 2,000 psi @ 72° F | 00000000 | 000000 |

Front and Back Sleeves for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Couple these sleeves with Yor-Lok nuts and fittings to create an extra-strong seal on stainless steel tubing. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube | Front Sleeve | Back Sleeve | |||||||

|---|---|---|---|---|---|---|---|---|---|

| OD | Wall Thick. | Sleeve Material | Lg. | No. Included | Lg. | No. Included | Max. Pressure | Each | |

Sleeves | |||||||||

| 1 1/4" | 0.083" | 316 Stainless Steel | 35/64" | 1 | 13/64" | 1 | 2,000 psi @ 72° F | 00000000 | 000000 |

Nuts for Yor-Lok Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid, Mineral Oil, Natural Gas, Steam, Water

- Temperature Range: -420° to 1200° F

- Tubing: Use with seamless or welded 304/304L or 316/316L stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Compatible With: Let-Lok, Parker A-Lok, Swagelok®

Use these nuts with Yor-Lok sleeves and fittings to create an extra-strong seal on stainless steel tubing. They are 316 stainless steel for excellent corrosion resistance.

For Tube | |||||

|---|---|---|---|---|---|

| OD | Wall Thick. | Nut Material | Max. Pressure | Each | |

| 1 1/4" | 0.083" | 316 Stainless Steel | 2,000 psi @ 72° F | 00000000 | 000000 |

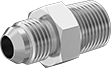

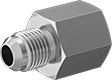

37° Flared Fittings for Stainless Steel Tubing

- Tubing: Use with welded or seamless 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514, except fittings with BSPP and BSPT threads meet SAE J514 only

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They withstand high pressure, so they’re often used in hydraulic applications. Made from 316 stainless steel, they resist corrosion from water and chemicals. A complete fitting requires a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

- For Use With: See table

- Temperature Range: See table

| For Tube OD | Pipe Size | For Use With | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | |||||||

|---|---|---|---|---|---|---|---|

| 1 1/4" | 1 1/4 | Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water | 316 Stainless Steel | 3,000 psi @ 72° F | -420° to 1200° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Pipe Size | Material | Max. Pressure | Temp. Range, °F | Each | |

NPT Threads | ||||||

|---|---|---|---|---|---|---|

| 1 1/4" | 1 1/4 | 316 Stainless Steel | 2,500 psi @ 72° F | -380° to 800° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 1 1/4" | 316 Stainless Steel | -420° to 1200° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: See table

| For Tube OD | Material | Temp. Range, °F | Each | |

| 1 1/4" | 316 Stainless Steel | -420° to 1200° | 000000000 | 0000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

| For Tube OD | Nut Material | Each | |

| 1 1/4" | 316 Stainless Steel | 000000000 | 000000 |

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 1 1/4" | 316 Stainless Steel | 000000000 | 000000 |

Nuts for 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Nuts are 316 stainless steel for excellent corrosion resistance.

| For Tube OD | Nut Material | Each | |

| 1 1/4" | 316 Stainless Steel | 000000000 | 000000 |

Sleeves for 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Hydraulic Fluid, Isopropyl Alcohol, Natural Gas, Phosphoric Acid, Water

- Temperature Range: -420° to 1,200° F

- Tubing: Use with seamless or welded 304 or 316 stainless steel that meets ASTM A213, ASTM A249, or ASTM A269

- Specifications Met: ISO 8434, SAE J514

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. Sleeves are 316 stainless steel for excellent corrosion resistance. They are also known as ferrules.

For Tube OD | |||

|---|---|---|---|

| Inch | Sleeve Material | Each | |

Inch | |||

| 1 1/4" | 316 Stainless Steel | 000000000 | 000000 |

Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See table

The threads on the tube end of these fittings are Class 3A or 3B and adhere to tighter tolerances than other 37° flared fittings. They are made to exact AS (formerly AN) specifications and provide a tight metal-to-metal seal on tubing that is flared to 37°. Fittings require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

| For Tube OD | Pipe Size | Max. Pressure | Specifications Met | Each | |

304 Stainless Steel | |||||

|---|---|---|---|---|---|

ANPT Threads | |||||

| 1 1/4" | 1 1/4 | 1,500 psi @ 72° F | AN816-20J, ASTM A380, SAE AS4841 | 00000000 | 0000000 |

| For Tube OD | Max. Pressure | Specifications Met | Each | |

316 Stainless Steel | ||||

|---|---|---|---|---|

| 1 1/4" | 1,500 psi @ 72° F | AN929-20K, ASTM A380, SAE AS4841 | 00000000 | 0000000 |

Nuts for Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

Use these nuts with precision AN sleeves and fittings to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. The threads are Class 3B and adhere to tighter tolerances than other nuts. They are made to exact AS (formerly AN) specifications.

304 stainless steel nuts have very good corrosion resistance. 316 stainless steel nuts have excellent corrosion resistance.

Sleeves for Precision AN 37° Flared Fittings for Stainless Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil, Water

- Temperature Range: -320° to 1200° F

- Tubing: Use with seamless 304 or 316 stainless steel

- Specifications Met: See Table

Use these sleeves with precision AN nuts and fittings to provide a tight metal-to-metal seal on stainless steel tubing that is flared to 37°. They are also known as ferrules.

304 stainless steel sleeves have very good corrosion resistance. 316 stainless steel sleeves have excellent corrosion resistance.

Butt-Weld Fittings for Stainless Steel Tubing

- For Use With: See table

- Temperature Range: See table

- Tubing:

304 Stainless Steel: Use with 304/304L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except DIN EN 10357 fittings with only ASTM A269 or ASTM A270

316 Stainless Steel: Use with 316/316L stainless steel that meets ASTM A213, ASTM A269, or ASTM A270, except ASME BPE and DIN EN 10357 fittings with only ASTM A269 or ASTM A270 - Specifications Met: See table

Weld these fittings to tubing for a permanent, flush connection that permits smooth flow through a line.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

Fittings with barbed hose end connect to hose with a hose clamp (sold separately).

316/316L Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| For Tube OD | For Hose ID | Max. Pressure | Max. Vacuum | Temp. Range | Wall Thick. | For Use With | Each | |

Dull | ||||||||

| 1 1/4" | 1 1/4" | Not Rated | Not Rated | Not Rated | 0.065" | Air, Food, Water | 000000000 | 000000 |

| For Tube OD | Max. Pressure | Max. Vacuum | Temp. Range Min., °F | Temp. Range Max., °F | Lg. | Wall Thick. | For Use With | Specifications Met | Each | |

304/304L Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Polished | ||||||||||

| 1 1/4" | 200 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 1 7/8" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 000000000 | 000000 |

Dull | ||||||||||

| 1 1/4" | 200 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 1 7/8" | 0.065" | Air, Water | __ | 000000000 | 00000 |

316/316L Stainless Steel | ||||||||||

Polished | ||||||||||

| 1 1/4" | 200 psi @ 72° F | 10 -6 torr @ 72° F | -65° | 250° | 1 7/8" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 000000000 | 00000 |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Max. Pressure | Max. Vacuum | Temp. Range, °F | Length | Wall Thick. | For Use With | Specifications Met | Each | |

Polished | |||||||||

| 1 1/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 2 3/4" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 000000000 | 000000 |

304/304L Stainless Steel | |||||||||

|---|---|---|---|---|---|---|---|---|---|

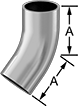

| For Tube OD | Max. Pressure | Max. Vacuum | Temp. Range, °F | Lg. (A) | Wall Thick. | For Use With | Specifications Met | Each | |

Polished | |||||||||

| 1 1/4" | 600 psi @ 72° F | 10 -6 torr @ 72° F | -65° to 250° | 1 21/32" | 0.065" | Dairy, Food | 3-A Certified 63-04 | 000000000 | 000000 |

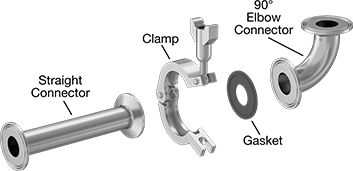

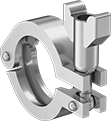

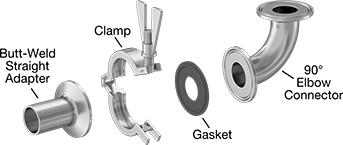

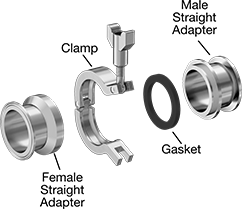

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

304 stainless steel fittings have very good corrosion resistance. 316 stainless steel fittings have excellent corrosion resistance.

3-A certified fittings comply with sanitary standards.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

- For Use With: Air, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- For Use With: Air, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

316 Stainless Steel | ||||

|---|---|---|---|---|

| For Tube OD | Flange OD | Pipe Size | Each | |

BSPP Threads | ||||

| 1 1/4" | 1.984" | 1 1/4 | 0000000 | 0000000 |

- For Use With:

3-A Certified Fittings: Air, Beverage, Food, Water

All Other Fittings: Air, Water - Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: See table

Fittings with barbed hose end connect flexible hose or tubing to your system. Secure with a hose clamp (sold separately).

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing:

Inch Fittings: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

Metric Fittings: Use with welded 304/304L or 316/316L stainless steel - Specifications Met: See table

Fittings with butt-weld end are also known as ferrules; they weld to tubing for a permanent, flush connection.

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing: Use with welded stainless steel that meets ASTM A269 or ASTM A270

- Specifications Met: See table

- For Use With: Air, Beverage, Dairy, Food, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM 270

- Specifications Met: 3-A Certified 63-04

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 316 Stainless Steel | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

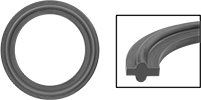

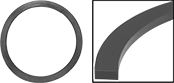

Buna-N gaskets are oil resistant. EPDM gaskets resist water and steam and work well in humid environments. Silicone gaskets withstand high temperatures. Fluoroelastomer gaskets stand up to fuel, oil, and acid condensates. PTFE gaskets withstand harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Buna-N Rubber | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

EPDM Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

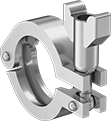

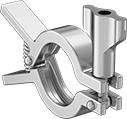

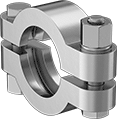

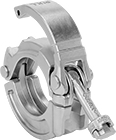

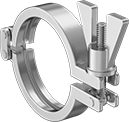

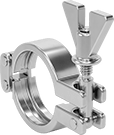

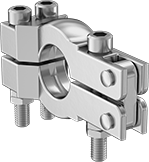

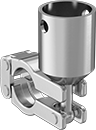

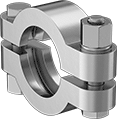

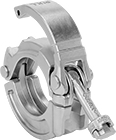

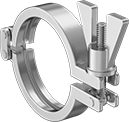

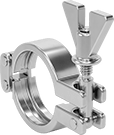

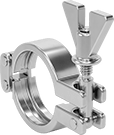

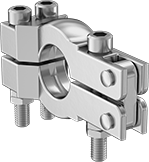

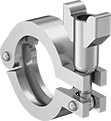

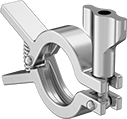

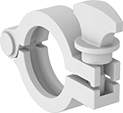

Clamps for High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets or O-Rings

- Tubing:

Inch 304 Stainless Steel and Nylon Plastic: Use with welded 304/304L and 316/316L stainless steel that meets ASTM A269 or ASTM A270, except ASME BPE: Use with welded or seamless 304/304L stainless steel that meets ASTM A269 or ASTM A270

Metric 304 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Inch 316 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Metric 316 Stainless Steel: Use with welded 316/316L stainless steel

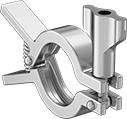

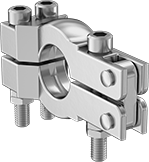

Connect quick-clamp sanitary tube fittings—also known as aseptic fittings—for a fast and easy way to access your line.

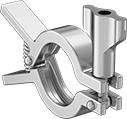

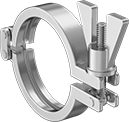

Wing nut—These clamps tighten by hand, no tools required. Clamps with a spring closure can be installed with one hand, as the spring holds the clamp in place. Clamps with a safety wing nut have a wider wing nut base and a narrower clamp gate than our other wing nut clamps, so they stay latched even when bumped and knocked. This is useful in steam lines where accidentally releasing the clamp could cause injuries. They also have a leak-before-burst design, so rather than bursting dangerously if the seal fails, they’ll safely relieve pressure by dripping instead.

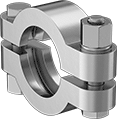

Bolt—These clamps handle higher pressures than wing-nut and lever clamps for a stronger, more secure hold. Tighten them with a wrench. Clamps with double-bolt meet ASME design standards for pressure vessels.

Lever—These clamps are best when you need to frequently open and close this connection. They reduce the risk of damage caused by over- or under-tightening the connection because the lever compresses the gasket evenly every time. This also creates a flush connection that minimizes spots where bacteria could grow. A threadless design prevents improper tightening caused by damaged threads. Easy to adjust, these clamps don't require tools to use and can be used with multiple gasket materials.

Recessed nut—These clamps are tamper resistant to reduce the risk of product contamination. A hex socket adapter is required to loosen the nut. They have a leak-before-burst design, so rather than burst dangerously if the seal fails, they’ll safely relieve pressure by dripping instead.

Clamps with a hole for a lockout help you comply with Hazard Analysis and Critical Control Point (HACCP) programs and Good Management Practices (GMP).

Clamps with a two-pin hinge require less clearance to open than other clamps. Use these for installation in tight spaces.

304 stainless steel clamps have very good corrosion resistance. 316 stainless steel clamps are more corrosion resistant than 304 stainless steel clamps. Nylon clamps are lightweight compared to stainless steel clamps.

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 1,500 psi @ 72° F | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | 00000000 | 000000 |

The temperature rating of the fitting will vary depending on the gasket or O-ring material you choose. Buna-N is oil resistant. EPDM resists water and steam and works well in humid environments. Silicone withstands high temperatures. Fluoroelastomer stands up to fuel, oil, and acid condensates. PTFE withstands harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Gaskets | ||||||||

|---|---|---|---|---|---|---|---|---|

Buna-N Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

EPDM Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Fluoroelastomer Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

Extra-High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- For Use With: Air, Beverage, Dairy, Deionized Water, Food, Pharmaceuticals, Water

- Temperature Range: See Gaskets

- Tubing:

Fittings with 700 psi @ 72° F max. pressure: Use with 316/316L stainless steel that meets ASTM A269 or ASTM A270

Fittings with all other max. pressures: Use with 316/316L stainless steel that meets ASTM A249, ASTM A269, or ASTM A270

Gaskets: Use with 304/304L and 316/316L stainless steel - Specifications Met: See table

- Certification: Material Certificate with Traceable Lot Number and Test Report

Polished to a 20 Ra finish, these fittings have an extra-smooth interior that prevents product buildup and inhibits bacteria growth. Use them in pharmaceutical and bioprocessing applications. Also known as tri-clamp fittings, they connect with a clamp, a gasket, and another quick-clamp fitting for a fast and easy way to access your line. Fittings are 316 stainless steel for excellent corrosion resistance.

Fittings with barbed hose end connect flexible hose or tubing to your system. Secure with a hose clamp (sold separately).

The pressure rating of the fitting will depend on the clamp you choose.

The temperature rating of the fitting will vary depending on the gasket material you choose.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

| For Tube OD | Flange OD | For Hose ID | Length | Material | Max. Pressure | Specifications Met | Each | |

| 1 1/4" | 1.984" | 1 1/4" | 1 11/16" | 316/316L Stainless Steel | 200 psi @ 100° F | ASME BPE | 00000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 316 Stainless Steel | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

37° Flared Fittings for Steel Tubing

- For Use With: Air, Cutting Oil, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Also known as JIC (Joint Industrial Council) fittings, these provide a tight metal-to-metal seal on tubing that is flared to 37°. They require a nut and a sleeve (ferrule) for each tube end. Nuts and sleeves are sold separately. Fittings are zinc-plated steel for fair corrosion resistance.

NPTF (Dryseal) threads are compatible with NPT threads.

- Temperature Range: -60° to 400° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1 1/4" | 1 1/4 | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 000000 |

- Temperature Range: -60° to 400° F

Fittings that swivel until tightened have a built-in nut that rotates 360° for easy installation.

Fittings with female tube end have an internal flare that mates with the male tube end of another fitting.

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1 1/4" | 1 1/4 | Zinc-Plated Steel | 2,500 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: NPT: -65° to 400° F

NPTF and BSPT: -60° to 400° F

Metric and BSPP with O-Rings: -30° to 200°F

BSPP with Washers: -20° to 212° F

| For Tube OD | Pipe Size | Material | Max. Pressure | Each | |

NPTF Threads | |||||

|---|---|---|---|---|---|

| 1 1/4" | 1 1/4 | Zinc-Plated Steel | 1,150 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1 1/4" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Material | Max. Pressure | Each | |

| 1 1/4" | Zinc-Plated Steel | 4,000 psi @ 72° F | 000000000 | 000000 |

- Temperature Range: -60° to 400° F

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

For Tube OD | ||||

|---|---|---|---|---|

| Inch | Sleeve Material | Max. Pressure | Each | |

Inch Sleeves | ||||

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 00000 |

- Temperature Range: -60° to 400° F

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 000000 |

Nuts for 37° Flared Fittings for Steel Tubing

- For Use With: Air, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Temp. Range: -60° to 400° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. They are zinc-plated steel for fair corrosion resistance.

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 000000 |

Sleeves for 37° Flared Fittings for Steel Tubing

- For Use With: Air, Fuel Oil, Hydraulic Fluid, Mineral Oil

- Temp. Range: -60° to 400° F

- Tubing: Use with seamless steel

- Specifications Met: SAE J514

Use these sleeves with a nut and fitting to provide a tight metal-to-metal seal on steel tubing that is flared to 37°. Sleeves are zinc-plated steel for fair corrosion resistance. They are also known as ferrules.

For Tube OD | ||||

|---|---|---|---|---|

| Inch | Sleeve Material | Max. Pressure | Each | |

Inch Sleeves | ||||

| 1 1/4" | Zinc-Plated Steel | 2,000 psi @ 72° F | 00000000 | 00000 |

Nuts for 37° Flared Fittings for Aluminum Tubing

- For Use With: Air, Coolant, Gasoline, Hydraulic Fluid, Water

- Temperature Range: -60° to 350° F

- Tubing: Use with seamless aluminum

Use these nuts with a sleeve and fitting to provide a tight metal-to-metal seal on aluminum tubing that is flared to 37°. Nuts are aluminum, which is lightweight with good corrosion resistance.

| For Tube OD | Nut Material | Max. Pressure | Each | |

| 1 1/4" | Anodized 2024 Aluminum | 1,500 psi @ 72° F | 0000000 | 000000 |

Drain, Waste, and Vent ABS Pipe Fittings for Chemicals

These Schedule 40 fittings are an economical option for gravity-flow chemical waste systems. They are ABS plastic, which has excellent strength and impact resistance and good chemical resistance. Fittings meet ASTM D2661, ASTM D3311, ASTM D3965, and ASTM F1498 specifications and testing requirements for material quality and product dimensions.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with ABS cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Sealants cannot be sold to Colorado, Connecticut, District of Columbia, Delaware, Illinois, Indiana, Massachusetts, Maryland, Maine, Michigan, New Hampshire, New Jersey, Northern Virginia, New York, Ohio, Pennsylvania, Rhode Island, or Utah due to local VOC (Volatile Organic Compounds) regulations.

- For Use With: Sodium Hydroxide

- Maximum Temperature: 180° F

- Specifications Met: ASTM D2661, ASTM D3311, ASTM D3965, ASTM F1498

- Flanges: Use Schedule 40 ABS Plastic

Fittings with a compression end are also known as slip-joint fittings. Insert the tube into the compression end and turn the nut until hand tight. Since you don't have to wait for cement to dry, they are quicker to install than socket-connect fittings.

Aboveground Standard-Wall PVC Pipe Fittings for Drain, Waste, and Vent

- For Use With: Water

- Max. Temperature: 140° F

- Specifications Met: ASTM D1784, ASTM D2665

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Schedule 40 PVC Plastic

These Schedule 40 fittings are the industry standard for gravity-flow drain, waste, and vent (DWV) applications. Fittings are PVC, which has good corrosion resistance. They meet ASTM D1784 and ASTM D2665 specifications and testing requirements for material quality.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

Fittings with a compression end are also known as slip-joint fittings. Insert the tube into the compression end and turn the nut until hand tight. Since you don't have to wait for cement to dry, they are quicker to install than socket-connect fittings.

Gaskets for 37° Flared Tube Fittings

Prevent leaks from temperature fluctuations and vibration that can loosen 37° flared tube fittings. In general, you should match your gasket material to your fitting material. But, if you have a brass fitting, you can use a copper gasket.

Gaskets without a coating are best for fittings that are exposed to harsh chemicals, such as antifreeze, which can dissolve the threadlocker coating.

Threadlocker-coated gaskets offer a more secure hold than uncoated gaskets, so they’re best for areas with high vibration.

Thread | Temperature, °F | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Dash Size | Size | Type | Thickness | Maximum Pressure, psi | Min. | Max. | Each | |

304 Stainless Steel | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | Not Rated | 2500° | 00000000 | 000000 |

Threadlocker-Coated 304 Stainless Steel—Orange | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 300° | 00000000 | 00000 |

316 Stainless Steel | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | Not Rated | 2500° | 00000000 | 00000 |

Threadlocker-Coated 316 Stainless Steel—Black | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 1200° | 00000000 | 0000 |

Threadlocker-Coated 316 Stainless Steel—Green | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 300° | 00000000 | 00000 |

Copper | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -420° | 800° | 00000000 | 00000 |

Threadlocker-Coated Copper—Purple | |||||||||

| 1 1/4" | 20 | 1 5/8"-12 | UN/UNF (JIC) | 0.335" | 20,000 | -40° | 300° | 00000000 | 00000 |

Extra-Support High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- For Use With: Dairy, Water

- Temperature Range: -30° to 200° F

- Tubing:

304 Stainless Steel: Use with welded 304/304L or 316/316L stainless steel that meets ASTM A269 or ASTM A270

316 Stainless Steel: Use with welded 304/304 L or 316/316L stainless steel - Specifications Met: See table

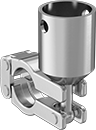

Also known as I-line fittings, these fittings have a male adapter that interlocks with a female adapter for more support than standard quick-clamp fittings. They permit easy access to your line. With a smooth finish on the interior, they prevent bacterial growth and help you remove product residue. The pressure rating of the fitting will depend on the clamp you choose.

316 stainless steel fittings have excellent corrosion resistance.

Note: To complete a connection, you’ll need a male and female straight adapter, a clamp, and a gasket (all sold separately).

| For Tube OD | Flange OD | Material | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 316/316L Stainless Steel | 3-A Certified 63-04 | 000000000 | 00000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

304 Stainless Steel with Wing Nut | ||||

|---|---|---|---|---|

| 1", 1 1/2" | 1.995" | 700 psi @ 72° F | 0000000 | 000000 |

Clamps with wing nut tighten by hand. Clamps with bolt tighten with a wrench.

| For Tube OD | For Flange OD | Max. Pressure | Each | |

304 Stainless Steel with Wing Nut | ||||

|---|---|---|---|---|

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72 ° F | 00000000 | 000000 |

304 Stainless Steel with Wing Nut, Spring Closure | ||||

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72 ° F | 0000000 | 00000 |

304 Stainless Steel with Bolt | ||||

| 1", 1 1/4", 1 1/2" | 1.984" | 1,500 psi @ 72 ° F | 00000000 | 00000 |

White Nylon Plastic with Wing Nut | ||||

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72 ° F | 00000000 | 00000 |

Buna-N gaskets are oil resistant.

| For Tube OD | ID | OD | Thick. | Color | Specifications Met | Each | |

Oil-Resistant Buna-N Rubber | |||||||

|---|---|---|---|---|---|---|---|

| 1" | 0.896" | 1.196" | 3/32" | Black | 3-A Certified 63-04 | 0000000 | 00000 |

| 1" | 0.900" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

| 1 1/2" | 1.438" | 1 3/4" | 3/32" | Black | 3-A Certified 63-04 | 0000000 | 0000 |

Water- and Steam-Resistant EPDM Rubber | |||||||

| 1" | 0.900" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

High-Temperature Silicone Rubber | |||||||

| 1" | 0.900" | 1.980" | 0.203" | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Chemical-Resistant Fluoroelastomer Rubber | |||||||

| 1" | 0.900" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

Ultra-Chemical-Resistant PTFE Plastic | |||||||

| 1" | 0.900" | 1.980" | 0.18" | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

Ultra-Chemical-Resistant Metal-Detectable 316 Stainless Steel/PTFE Plastic Blend | |||||||

| 1" | 0.910" | 1.270" | 0.072" | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |

| 1 1/2" | 1.410" | 1.760" | 0.072" | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, USP VI Certified | 0000000 | 00000 |