How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

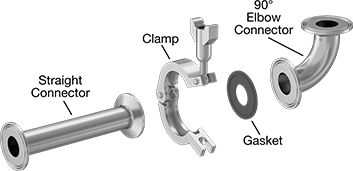

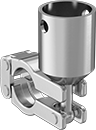

High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets

The smooth finish inside these fittings makes it easy to remove product residue. Also known as aseptic and tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for a fast and easy way to access your line. The pressure rating of the fitting will vary depending on the clamp you choose, and the temperature rating will vary based on the gasket material you choose.

316 stainless steel fittings have excellent corrosion resistance.

Fittings that meet DIN standards adhere to international requirements for sanitary quick-clamp fittings.

Note: To complete a connection, you’ll need two quick-clamp fittings, a clamp, and a gasket (all sold separately).

- For Use With: Air, Water

- Tubing: Use with welded 304/304L or 316/316L stainless steel

- Specifications Met: DIN 32676

For Tube OD | Flange OD | 316 Stainless Steel | ||||

|---|---|---|---|---|---|---|

| Quick Clamp | Metric Quick Clamp, mm | Quick Clamp | Metric Quick Clamp, mm | Wall Thick. | Each | |

| 1 1/2" | 40 | 1.984" | 52.5 | 0.122" | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 304 Stainless Steel | 1,500 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASTM A269, ASTM A270 | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Bolt Material | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 316 Stainless Steel | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | For Tube Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | ASTM A269, ASTM A270 | 00000000 | 000000 |

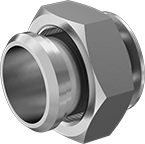

For Tube OD | |||||||

|---|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Includes | Each | |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 304 Stainless Steel Nut | 0000000 | 0000000 |

For Tube OD | ||||||

|---|---|---|---|---|---|---|

| Gasket Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1 1/2" | 1 1/2" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 0000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

Flange OD | |||||||

|---|---|---|---|---|---|---|---|

| For Tube OD | Extra-Support Connection | Standard Connection | Wall Thick. | Material | For Tube Specifications Met | Each | |

| 1 1/2" | 1.995" | 1.984" | 0.065" | 316 Stainless Steel | ASTM A269, ASTM A270 | 0000000 | 000000 |

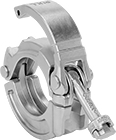

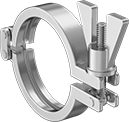

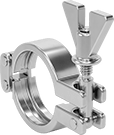

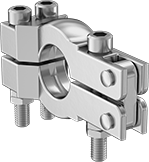

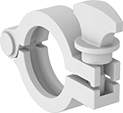

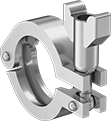

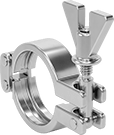

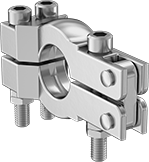

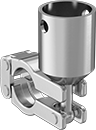

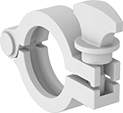

Clamps for High-Polish Metal Quick-Clamp Sanitary Tube Fittings

- Temperature Range: See Gaskets or O-Rings

- Tubing:

Inch 304 Stainless Steel and Nylon Plastic: Use with welded 304/304L and 316/316L stainless steel that meets ASTM A269 or ASTM A270, except ASME BPE: Use with welded or seamless 304/304L stainless steel that meets ASTM A269 or ASTM A270

Metric 304 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Inch 316 Stainless Steel: Use with welded 304/304L and 316/316L stainless steel

Metric 316 Stainless Steel: Use with welded 316/316L stainless steel

Connect quick-clamp sanitary tube fittings—also known as aseptic fittings—for a fast and easy way to access your line.

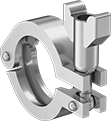

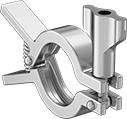

Wing nut—These clamps tighten by hand, no tools required. Clamps with a spring closure can be installed with one hand, as the spring holds the clamp in place. Clamps with a safety wing nut have a wider wing nut base and a narrower clamp gate than our other wing nut clamps, so they stay latched even when bumped and knocked. This is useful in steam lines where accidentally releasing the clamp could cause injuries. They also have a leak-before-burst design, so rather than bursting dangerously if the seal fails, they’ll safely relieve pressure by dripping instead.

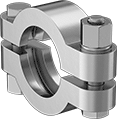

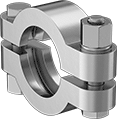

Bolt—These clamps handle higher pressures than wing-nut and lever clamps for a stronger, more secure hold. Tighten them with a wrench. Clamps with double-bolt meet ASME design standards for pressure vessels.

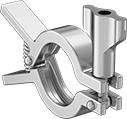

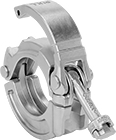

Lever—These clamps are best when you need to frequently open and close this connection. They reduce the risk of damage caused by over- or under-tightening the connection because the lever compresses the gasket evenly every time. This also creates a flush connection that minimizes spots where bacteria could grow. A threadless design prevents improper tightening caused by damaged threads. Easy to adjust, these clamps don't require tools to use and can be used with multiple gasket materials.

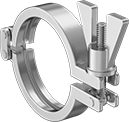

Recessed nut—These clamps are tamper resistant to reduce the risk of product contamination. A hex socket adapter is required to loosen the nut. They have a leak-before-burst design, so rather than burst dangerously if the seal fails, they’ll safely relieve pressure by dripping instead.

Clamps with a hole for a lockout help you comply with Hazard Analysis and Critical Control Point (HACCP) programs and Good Management Practices (GMP).

Clamps with a two-pin hinge require less clearance to open than other clamps. Use these for installation in tight spaces.

304 stainless steel clamps have very good corrosion resistance. 316 stainless steel clamps are more corrosion resistant than 304 stainless steel clamps. Nylon clamps are lightweight compared to stainless steel clamps.

Clamps that meet DIN 11864 or DIN 32676 adhere to international standards for sanitary quick-clamp fittings.

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 1,500 psi @ 72° F | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 500 psi @ 72° F | ASME BPE | 00000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 32mm, 40mm | 64mm | 725 psi @ 300° F | DIN 11864 | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 700 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Specifications Met | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 2,400 psi @ 72° F | ASME BPVC.VIII | 0000000 | 0000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 720 psi @ 72° F | 0000000 | 000000 |

| For Tube OD | For Flange OD | Max. Pressure | Each | |

| 1", 1 1/4", 1 1/2" | 1.984" | 150 psi @ 72° F | 00000000 | 000000 |

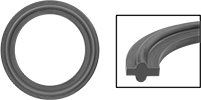

The temperature rating of the fitting will vary depending on the gasket or O-ring material you choose. EPDM resists water and steam and works well in humid environments. Fluoroelastomer stands up to fuel, oil, and acid condensates. PTFE withstands harsh chemicals, with the exception of molten alkali metal and elemental fluorine.

| For Tube OD | ID | OD | Thick. | Temp. Range, °F | Color | Specifications Met | Each | |

Gaskets | ||||||||

|---|---|---|---|---|---|---|---|---|

Buna-N Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -30° to 200° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 000 |

EPDM Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -20° to 300° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 32mm | 32.200mm | 50.500mm | 0.205" | -50° to 275° | Black | DIN 32676 | 0000000 | 0000 |

Silicone Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -40° to 450° | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 32mm | 32.500mm | 52.580mm | 5.2mm | -40° to 450° | Clear | DIN 32676, FDA Compliant 21 CFR 177.2600 | 00000000 | 00000 |

Fluoroelastomer Rubber | ||||||||

| 1" | 0.900" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000 |

PTFE Plastic | ||||||||

| 1" | 0.900" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 1 1/2" | 1.400" | 1.980" | 0.18" | -100° to 500° | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 0000 |

| 32mm | 32.200mm | 50.500mm | 5.2mm | -100° to 500° | White | DIN 32676, FDA Compliant 21 CFR 177.1550 | 000000000 | 00000 |

O-Rings | ||||||||

EPDM Rubber | ||||||||

| 32mm | 34.000mm | 44.000mm | __ | 32° to 280° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

| 40mm | 40.000mm | 50.000mm | __ | 32° to 280° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

Viton® Fluoroelastomer Rubber | ||||||||

| 32mm | 34.000mm | 44.000mm | __ | 32° to 300° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

| 40mm | 40.000mm | 50.000mm | __ | 32° to 300° | Black | 3-A Certified 18-00 | 0000000 | 00000 |

PTFE Plastic | ||||||||

| 32mm | 34.000mm | 44.000mm | __ | 32° to 280° | White | 3-A Certified 18-00 | 0000000 | 00000 |

| 40mm | 40.000mm | 50.000mm | __ | 32° to 280° | White | 3-A Certified 18-00 | 0000000 | 00000 |