Filter by

Tube OD

Fitting Connection

Power Source

Material

Length

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Drive Style

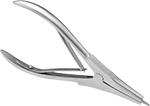

Soft Tubing Expanding Pliers

Hammer-Driven Tube End Expanders

|

For Tube OD | For Max. Wall Thk. | Lg. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" to 3 5/8" | 0.078" | 8" | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tube Expanders for Impact Wrenches

For Tube OD | For Max. Wall Thk. | For Square Drive Size | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2", 2 3/8", 2 3/4", 3 1/8", 3 1/2", 3 7/8", 4 1/4" | 3/16" | 1/2", 3/4" | Five Aluminum Expander Heads (For 2 3/4", 3 1/8", 3 1/2", 3 7/8" and 4 1/4" Tube ODs); One Black-Oxide Steel Expander Head (For 2 3/8" Tube OD); One Black-Oxide Steel Tool with 1 1/8" External Hex Drive and Expander Head (For 2" Tube OD) | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tube Flarers and Expanders for 45° Flares

|  |

For Tube OD | For Tube OD for Expanding | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/8", 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4" | 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4" | 6 3/4" | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hammer-Driven Tube Expanders

|  |  |  |

For 3/16", 1/4", 5/16", 3/8", 1/2", 5/8" Tube OD | For 3/4" OD Tubes | For 7/8" OD Tubes | Tube Holder |

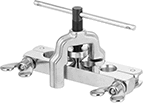

Tube Expanders for Condensers, Heat Exchangers, and Boilers

For Tube Size | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

OD | Gauge | For Min. Tube ID | Max. Tube Expansion Dia. | For Max. Tube Sheet Thk. | Lg. | Body Material | Head Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 18 | 0.392" | 0.447" | 1 1/2" | 7 3/8" | Steel | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 16 | 0.485" | 0.55" | 1 1/2" | 8 1/2" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 18 | 0.517" | 0.582" | 1 1/2" | 8 1/2" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 15 | 0.596" | 0.661" | 1 1/2" | 8 1/2" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 17-18 | 0.619" | 0.699" | 1 1/2" | 9" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 14 | 0.685" | 0.774" | 2 1/4" | 9 3/8" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 14 | 0.81" | 0.909" | 2 1/4" | 9 3/4" | Steel | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hammer-Driven Tube Flarers for 45° Flares

|

|

|

Tube Holder |

Tube Flarers | Vise Tube Holders | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Tube OD | For Copper Tube Size | Lg. | Material | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" | 3/8 | 2 3/4" | Steel | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2 | 2 3/4" | Steel | 0000000 | 00000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 5/8 | 3 1/4" | Steel | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/8" | 3/4 | 3 1/2" | Steel | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1 | 4" | Steel | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/8" | 1 1/4 | 4 1/4" | Steel | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 5/8" | 1 1/2 | 4 1/2" | Steel | 0000000 | 00000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 1/8" | 2 | 4 3/4" | Steel | 0000000 | 000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hand-Held Tube Flarers for Single and Double 45° Flares

|  |

For Tube OD | For Tube OD for Double Flare | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16", 1/4", 5/16", 3/8", 1/2" | 3/16", 1/4", 5/16", 3/8", 1/2" | 7 1/2" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tube Expanders

|

For Tube OD | For Max. Wall Thk. | Lg. | Body Material | Head Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2", 5/8", 7/8", 1 1/8" | 0.063" | 24" | Aluminum | Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vise-Mount Tube Flarers and Reamers for 37° Flares

|  |

For Tube OD | For Tube OD for Reaming | Lg. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16", 1/4", 5/16", 3/8", 1/2", 5/8" | 1/4", 5/16", 3/8", 1/2", 5/8" | 6 1/8" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vise-Mount Tube Flarers for 37° and 45° Flares

For Tube OD | For Tube OD for Double Flare | Lg. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper, Stainless Steel, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/16", 1/4", 5/16", 3/8", 4.75 mm | 4.75 mm, 3/16", 1/4", 5/16", 3/8" | 11" | Steel | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hand-Held Tube Flarers for 37° Flares

Tube Beaders

Vise-Mount Tube Flarers for 37° Flares

Hand-Held Tube Flarers for 45° Flares

|

|  |  |

Style A | Style B | Style C |

|  | |

Style D | Style E |

Style | For Tube OD | For Copper Tube Size | Lg. | For Square Drive Size | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Aluminum, Brass, Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1/8", 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4" | 1/4, 3/8, 1/2, 5/8 | 6 3/4" | — | — | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8" | 1/4, 3/8, 1/2 | 7" | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1/8", 3/16", 1/4", 5/16", 3/8", 1/2", 5/8", 3/4" | 1/4, 3/8, 1/2, 5/8 | 8" | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 3/16", 1/4", 5/16", 3/8", 1/2", 5/8" | 1/4, 3/8, 1/2 | 10" | — | — | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Aluminum, Brass, Copper, Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5/8", 3/4", 7/8", 1 1/8" | 1/2, 5/8, 3/4, 1 | 7 1/2" | — | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 3/16", 1/4", 5/16", 3/8", 1/2", 5/8", 4 mm, 6 mm, 8 mm, 10 mm, 12 mm, 15 mm, 16 mm | 1/4, 3/8, 1/2 | 4 5/8" | — | — | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 1/4", 5/16", 3/8", 1/2", 5/8", 3/4" | 1/4, 3/8, 1/2, 5/8 | 9 1/4" | 3/8" | 1/8"-1 1/8" Tube Cutter, 3/8" Male Square Drive × 5/16" Hex Shank Adapter for Power Tools | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||