Filter by

Wire Diameter

Export Control Classification Number (ECCN)

DFARS Specialty Metals

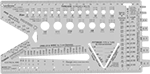

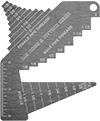

Pipe, Tubing, and Hose Size Identifiers

|  |

For Pipe, Tubing, And Hose | For Pipe, Pipe Fittings, And Hose |

For Use With | For Pipe Size | For Pipe Fitting Size | For Tube OD | For Hose ID | Includes | Wd. | Ht. | Thk. | Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Inch | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pipe, Hose, Tubing | 1/8, 1/4, 3/8, 1/2, 3/4 | — | 1/8", 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4", 1" | 1/4", 3/8", 1/2", 3/4", 1" | Compression Fitting Chart | 9" | 3 3/4" | 7/64" | Blue | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pipe, Pipe Fittings, Hose | 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | — | 1/8", 1/4", 5/16", 3/8", 5/8", 3/4", 7/8", 1", 1 1/8", 1 1/4" | — | 3 3/4" | 4 1/2" | 1/32" | Silver | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

All-in-One Identifiers

For Use With | For Screw Size | For Drill Bit Size | For Pipe Size | For Pipe Fitting Size | Wd. | Ht. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Screws, Bolts, Threaded Rods, Drill Bits, Nails, Nuts, Tube Fittings, Pipe, Pipe Fittings, Tubing, Wire | No. 2, No. 3, No. 4, No. 5, No. 6, No. 8, No. 10, No. 12, 1/4", 5/16", 3/8", 7/16", 1/2", M3, M4, M5, M6, M8, M10, M12 | 1/32", 3/64", 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 11/64", 3/16", 13/64", 7/32", 15/64", 1/4", 17/64", 9/32", 19/64", 5/16", 21/64", 11/32", 23/64", 3/8", 25/64", 13/32", 27/64", 7/16", 29/64", 15/32", 31/64", 1/2", 65 Ga., 60 Ga., 55 Ga., 50 Ga., 45 Ga., 40 Ga., 35 Ga., 30 Ga., 25 Ga., 20 Ga., 15 Ga., 10 Ga., 5 Ga., A, F, K, P, U, Z | 1/16, 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2, 2 1/2, 3, 3 1/2, 4, 5, 6 | 1/16, 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 10 1/2" | 3 1/2" | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Screws, Bolts, Threaded Rods, Drill Bits, Nails, Nuts, Tube Fittings, Pipe, Pipe Fittings, Tubing, Wire | No. 2, No. 3, No. 4, No. 5, No. 6, No. 8, No. 10, No. 12, 1/4", 5/16", 3/8", 7/16", 1/2", M3, M4, M5, M6, M8, M10, M12 | 1/16", 5/64", 3/32", 7/64", 1/8", 9/64", 5/32", 11/64", 3/16", 13/64", 7/32", 15/64", 1/4", 17/64", 9/32", 19/64", 5/16", 21/64", 11/32", 23/64", 3/8" | 1/8, 1/4, 3/8, 1/2, 3/4, 1, 1 1/4, 1 1/2, 2 | 1/8, 1/4, 3/8, 1/2, 3/4, 1 | 8 11/16" | 4 1/4" | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

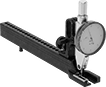

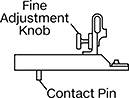

Shallow Inside/Outside Diameter Gauges

Inside Measuring Lg. Range | Outside Measuring Lg. Range | Max. Dp. Measured | Material | Overall Lg. | Overall Ht. | Heat Treatment | Container Type | Features | Includes | Each | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.55" to 7.2" | 0.24" to 6.92" | 0.4" | Black-Oxide Tool Steel | 7 3/4" | 2 3/4" | Hardened | Cardboard Box | Fine-Adjustment Knob, Indicator Contact Point Stopper | Contact Pin, Two L-Keys | 0000000 | 0000000 | |

| 2" to 12.1" | 1.95" to 12.05" | 0.4" | Black-Oxide Tool Steel | 12 7/8" | 2 3/4" | Hardened | Plastic Box | Fine-Adjustment Knob, Indicator Contact Point Stopper | Contact Pin, Two L-Keys | 0000000 | 000000 |

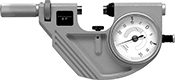

Outside Micrometers for Tolerance Checking

Accuracy | Measuring Increments | Outside Micrometers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Measuring Range | Inch | Metric | Inch | Metric, mm | Thimble Type | Throat Dp. | Frame Material | Measurement Scale Type | Mfr. Model No. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Mitutoyo | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Dual Spindle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0 mm to 25 mm | — | ±0.003 mm | — | 0.01 | Plain | 0.905" | Steel | Vernier | 113-102 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 25 mm to 50 mm | — | ±0.003 mm | — | 0.01 | Plain | 1.456" | Steel | Vernier | 113-103 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

With Dial Display | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0" to 1" | ±0.00005" | — | 0.00005" | — | Plain | 0.984" | Steel | — | 523-131 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" to 2" | ±0.00005" | — | 0.00005" | — | Plain | 1.378" | Steel | — | 523-132 | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Go/No-Go Outside Diameter Gauges

Gauges | Indicators | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Anvil Face | |||||||||||||

Distance Measured Range | Measuring Range Tolerance | Throat Dp. | Lg. | Wd. | Material | Frame Material | Mfr. | Mfr. Model No. | Each | Each | |||

| 0" to 1" | 0.078" | 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-151 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 1" to 2" | 0.078" | 1" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-152 | 0000000 | 000000 | 0000000 | 000000 | |

| 2" to 3" | 0.078" | 1 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-153 | 0000000 | 000000 | 0000000 | 000000 | |

| 3" to 4" | 0.078" | 2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-154 | 0000000 | 000000 | 0000000 | 000000 | |

| 4" to 5" | 0.078" | 2 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-155 | 0000000 | 000000 | 0000000 | 000000 | |

| 5" to 6" | 0.078" | 3" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-156 | 0000000 | 000000 | 0000000 | 000000 | |

| 0 mm to 25 mm | 2 mm | 12.5 mm | 13.5 mm | 12 mm | Carbide | Steel | Mitutoyo | 201-101 | 0000000 | 000000 | 0000000 | 000000 | |

| 25 mm to 50 mm | 2 mm | 25 mm | 13.5 mm | 12 mm | Carbide | Steel | Mitutoyo | 201-102 | 0000000 | 000000 | 0000000 | 000000 | |

Go/No-Go Outside Diameter Gauges with Calibration Certificate

Gauges | Indicators | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Anvil Face | |||||||||||||

Distance Measured Range | Measuring Range Tolerance | Throat Dp. | Lg. | Wd. | Material | Frame Material | Mfr. | Mfr. Model No. | Each | Each | |||

| 0" to 1" | 0.078" | 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-151 | 0000000 | 0000000 | 0000000 | 0000000 | |

| 1" to 2" | 0.078" | 1" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-152 | 0000000 | 000000 | 0000000 | 000000 | |

| 2" to 3" | 0.078" | 1 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-153 | 0000000 | 000000 | 0000000 | 000000 | |

| 3" to 4" | 0.078" | 2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-154 | 0000000 | 000000 | 0000000 | 000000 | |

| 4" to 5" | 0.078" | 2 1/2" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-155 | 0000000 | 000000 | 0000000 | 000000 | |

| 5" to 6" | 0.078" | 3" | 0.53" | 0.47" | Carbide | Steel | Mitutoyo | 201-156 | 0000000 | 000000 | 0000000 | 000000 | |

| 0 mm to 25 mm | 2 mm | 12.5 mm | 13.5 mm | 12 mm | Carbide | Steel | Mitutoyo | 201-101 | 0000000 | 000000 | 0000000 | 000000 | |

| 25 mm to 50 mm | 2 mm | 25 mm | 13.5 mm | 12 mm | Carbide | Steel | Mitutoyo | 201-102 | 0000000 | 000000 | 0000000 | 000000 | |