About Plastic and Rubber Tubing

More

About Hose

More

High-Purity Soft Plastic and Rubber Tubing

Designed for high-purity processes, this tubing is made without plasticizers like DEHP that can contaminate the fluid passing through it. It meets USP Class VI specifications for material testing; it is not for use in medical applications. Tubing is clear or semi-clear, so you can monitor flow. It’s also flexible and easily bends around objects.

Tubing with braid reinforcement has extra strength to handle higher pressures than nonreinforced tubing.

For technical drawings and 3-D models, click on a part number.

- Manufacturer Equivalent Number:

Clear Tygon Plastic Blend Tubing without Polyester Braid Reinforcement: 2475

Clear Tygon Plastic Blend Tubing with Polyester Braid Reinforcement: 2475 I.B. - Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- Environment: Sanitary

- Temperature Range: -90° to 120° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Per Ft. | |

Without Polyester Braid Reinforcement | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 3/16" | 1/16" | 1/8" | 85 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1/8" | 1/4" | 1/16" | 1/4" | 50 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/16" | 5/16" | 1/16" | 1/2" | 40 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/4" | 3/8" | 1/16" | 3/4" | 30 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/16" | 7/16" | 1/16" | 1 1/4" | 15 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 1 3/4" | 20 psi @ 72° F | 25 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/2" | 3/4" | 1/8" | 1 1/2" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 2 1/4" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 3/4" | 1" | 1/8" | 3 1/4" | 20 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1" | 1 3/8" | 3/16" | 3" | 20 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

With Polyester Braid Reinforcement | ||||||||||

| 1/4" | 1/2" | 1/8" | 1/4" | 220 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/8" | 5/8" | 1/8" | 1" | 210 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/2" | 3/4" | 1/8" | 1 1/4" | 230 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 1 3/4" | 130 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 3/4" | 1 1/16" | 5/32" | 2 1/4" | 130 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1" | 1 3/8" | 3/16" | 3 1/2" | 120 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

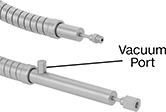

Touch-Safe Insulated Cryogenic Hose with Threaded Fittings

- Temperature Range: -325° to 200° F

- Material: 321 Stainless Steel with 304 Stainless Steel Cover

- Both Fittings Swivel Until Tightened

To maintain the temperature of liquids as cold as -325° F, this hose has vacuum insulation and a reflective barrier. This prevents heat transfer in the same way a thermos does, so the exterior of the hose won’t freeze or form condensation. Even when used with liquid argon, liquid carbon dioxide, liquid methane, and liquid nitrogen, this hose is safe to handle. It meets strict ASME design and testing standards for process piping systems.

This hose comes ready to use—you don’t need to create the vacuum yourself. To install, thread the fittings on this hose onto a freezer or other equipment in your plant or laboratory. Both ends swivel until tightened, so you don’t need to rotate the entire hose during installation. With ribbed insulation inside and spiral reinforcement outside, this hose won’t crack or leak when you bend and flex it around obstacles. The cover is 304 stainless steel, which stands up to wear and tear and won’t corrode from mild chemicals and water.

For technical drawings and 3-D models, click on a part number.

Tube Connection | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| CGA Number | For Tube OD | Thread Size | Pipe Size | ID | OD | Bend Radius | Max. Pressure | Specifications Met | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

316 Stainless Steel 37°, 45° Flared UN/UNF (JIC) Female × 316 Stainless Steel Threaded NPT Male | |||||||||||||||

| 295 | 1/4" | 7/16"-20 | 1/4 | 1/4" | 1 1/8" | 6 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 295 | 3/8" | 9/16"-18 | 3/8 | 3/8" | 1 3/8" | 7 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 295 | 1/2" | 3/4"-16 | 1/2 | 1/2" | 1 11/16" | 8 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

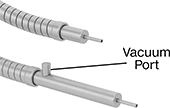

Touch-Safe Insulated Cryogenic Hose with Tube Stem Fittings

- Temperature Range: -325° to 200° F

- Material: 321 Stainless Steel with 304 Stainless Steel Cover

Sealed vacuum insulation and a reflective barrier inside this hose maintains the temperature of liquids as cold as -325° F. Similar to a thermos, this prevents heat transfer, so the exterior of the hose won’t freeze or form condensation. This hose is safe to handle, even when used with liquid nitrogen, liquid argon, liquid carbon dioxide, and liquid methane. It meets strict ASME design and testing standards for process piping systems.

The tube stems on each end slide into tube fittings on a freezer or other equipment in your plant or laboratory. With ribbed insulation inside and spiral reinforcement outside, this hose won’t crack or leak when you bend and flex it around obstacles. The cover is 304 stainless steel, which stands up to wear and tear and won’t corrode from mild chemicals and water.

For technical drawings and 3-D models, click on a part number.

| Stem OD | ID | OD | Bend Radius | Max. Pressure | Specifications Met | 3 ft. | 4 ft. | 6 ft. | 8 ft. | 10 ft. | 12 ft. | |

316 Stainless Steel Tube Stem × 316 Stainless Steel Tube Stem | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/4" × 1/4" | 1/4" | 1 1/8" | 6 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 3/8" × 3/8" | 3/8" | 1 3/8" | 7 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||

| 1/2" × 1/2" | 1/2" | 1 11/16" | 8 1/2" | 150 psi @ 72° F | ASME B31.3 | 0000000 | ||||||