How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Plastic and Rubber Tubing

More

High-Purity Soft Plastic and Rubber Tubing

Designed for high-purity processes, this tubing is made without plasticizers like DEHP that can contaminate the fluid passing through it. It meets USP Class VI specifications for material testing; it is not for use in medical applications. Tubing is clear or semi-clear, so you can monitor flow. It’s also flexible and easily bends around objects.

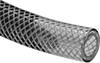

Tubing with braid reinforcement has extra strength to handle higher pressures than nonreinforced tubing.

- Manufacturer Equivalent Number:

Clear Tygon Plastic Blend Tubing without Polyester Braid Reinforcement: 2475

Clear Tygon Plastic Blend Tubing with Polyester Braid Reinforcement: 2475 I.B. - Flexible

- Compatible with Barbed Tube Fittings

- Soft (Durometer 70A)

- Environment: Sanitary

- Temperature Range: -90° to 120° F

| ID | OD | Wall Thick. | Bend Radius | Max. Pressure | Max. Vacuum | Color | Specifications Met | Lengths, ft. | Per Ft. | |

Without Polyester Braid Reinforcement | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/16" | 3/16" | 1/16" | 1/8" | 85 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1/8" | 1/4" | 1/16" | 1/4" | 50 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/16" | 5/16" | 1/16" | 1/2" | 40 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/4" | 3/8" | 1/16" | 3/4" | 30 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/16" | 7/16" | 1/16" | 1 1/4" | 15 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/8" | 1/2" | 1/16" | 1 3/4" | 20 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/2" | 3/4" | 1/8" | 1 1/2" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 2 1/4" | 25 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 3/4" | 1" | 1/8" | 3 1/4" | 20 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1" | 1 3/8" | 3/16" | 3" | 20 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

With Polyester Braid Reinforcement | ||||||||||

| 1/4" | 1/2" | 1/8" | 1/4" | 220 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 3/8" | 5/8" | 1/8" | 1" | 210 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 1/2" | 3/4" | 1/8" | 1 1/4" | 230 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 0000 | |

| 5/8" | 7/8" | 1/8" | 1 3/4" | 130 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 3/4" | 1 1/16" | 5/32" | 2 1/4" | 130 psi @ 72° F | 29 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

| 1" | 1 3/8" | 3/16" | 3 1/2" | 120 psi @ 72° F | 25 in. of Hg @ 72° F | Clear | USP Class VI | 0000000 | 00000 | |

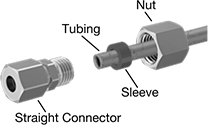

Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Compressed Air, Cutting Oil, Diesel Fuel, Fuel Oil, Gasoline, Helium, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Instead of a metal sleeve (ferrule), these fittings have a rubber sleeve that cushions tubing and absorbs vibration to maintain a tight seal, even when connected to large pumps. However, rubber sleeves can’t withstand temperatures as high as metal ones. To create the strong seal, tighten the included nut. These fittings are made of 316 stainless steel, so they have excellent corrosion resistance. They’re also known as flareless fittings. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

BSPP and metric male threads have a gasket to prevent leaks.

Male Threads with

Gasket and Washer

For Tube | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Pipe Size | Thread Size | Thread Pitch, mm | Material | Gasket Material | Maximum Pressure | Each | |

NPT Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 0000000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 00000 |

| 8 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | 3/8 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/4 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 12 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 15 | 1.5 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

| 18 | 2 | 1/2 | __ | __ | 316 Stainless Steel | __ | 4,500 psi @ 72° F | 00000000 | 000000 |

BSPP Threads | |||||||||

| 6 | 1 | 1/8 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 6 | 1 | 1/4 | __ | __ | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

Metric Threads | |||||||||

| 8 | 1 | __ | M12 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

| 10 | 1 | __ | M14 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

For Tube | |||||

|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Maximum Pressure | Each | |

| 6 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 000000 |

| 8 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 12 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 15 | 1.5 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

| 18 | 2 | 316 Stainless Steel | 4,500 psi @ 72° F | 00000000 | 00000 |

Nuts for Vibration-Resistant Compression Fittings for Stainless Steel Tubing

- For Use With: Acetylene, Air, Butane, Diesel Fuel, Compressed Air, Cutting Oil, Fuel Oil, Gasoline, Hydraulic Fluid (Petroleum Base), Kerosene, Mineral Oil, Natural Gas, Helium, Nitrogen, Propane, Soap Solutions

- Temperature Range: -10° to 400° F

- Tubing: Use with seamless 316Ti or 321 stainless steel

- Specifications Met: DIN 3861

Pair these nuts with vibration-resistant compression sleeves and fittings for a strong seal on stainless steel tubing. Made of 316 stainless steel, they have excellent corrosion resistance. All meet DIN 3861, which is an international standard for compression tube fitting specifications.

For Tube | ||||||

|---|---|---|---|---|---|---|

| OD, mm | Wall Thickness, mm | Nut Material | Sleeve Material | Maximum Pressure | Each | |

| 6 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 000000 |

| 8 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 10 | 1 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 12 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 15 | 1.5 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |

| 18 | 2 | 316 Stainless Steel | Fluoroelastomer Rubber | 4,500 psi @ 72° F | 00000000 | 00000 |