About Conduit

More

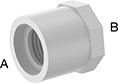

How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

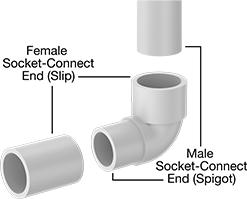

Standard-Wall Plastic Pipe Fittings for Water

Connect these fittings to Schedule 40 plastic pipe–they are the industry standard for residential and commercial low-pressure plumbing and water supply applications. They are plastic for good corrosion resistance.

Fittings for drinking water meet NSF/ANSI Standard 61.

Attach socket-connect ends to unthreaded pipe or another socket-connect fitting with a PVC primer and cement (also known as solvent weld).

To prevent leaks in threaded connections, apply a sealant to the male threads. Threaded connections can be taken apart as needed for maintenance and repair. For plastic threads, apply a non-hardening, plastic-compatible sealant. Tape or sealants with PTFE are not recommended for plastic-to-plastic connections. Fittings that meet ASTM D1784, ASTM D1785, and ASTM D4066 adhere to specifications and testing requirements for material quality.

Note: For fittings that are not rated for pressure, you can use the pressure rating of the plastic pipe as a reference. Threaded fittings are limited to 50% of the rated pressure of the pipe.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

- For Use With: Drinking Water, Water

- Maximum Temperature: 140° F

- Specifications Met: ASTM D1784, NSF/ANSI 61

- Pipe Nipples and Pipe: Use Schedule 40 PVC Plastic

- Flanges: Use Class 150 PVC Plastic

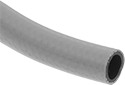

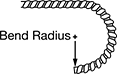

Continuous-Flex Liquid-Tight Plastic Conduit

Also known as Type A, this conduit meets the demands of continuous motion while sealing out liquid when used with liquid-tight fittings. A layer of nylon provides strength during flexing. This conduit is crush and abrasion resistant as well as flame retardant. It also resists oil, chemicals, and UV light.

One end twists into a piece of conduit for a quick connection; the other end attaches to a knockout in an outlet box or enclosure. These fittings seal out liquid when used with continuous-flex liquid-tight plastic conduit.

Acetal fittings resist corrosion and chemicals. Steel fittings are stronger than acetal.

One end twists into a piece of conduit for a quick connection; the other end attaches to a knockout in an outlet box or enclosure. These fittings seal out liquid when used with continuous-flex liquid-tight plastic conduit.

Acetal fittings resist corrosion and chemicals. Steel fittings are stronger than acetal.