How to Identify and Measure Fittings

Pipe size is an industry designation, not the actual size. View information about how to measure threaded and unthreaded pipe and pipe fittings.

More

About Conduit

More

Standard-Wall Brass Threaded Pipe Nipples and Pipe

Also known as Schedule 40, this pipe is for use in low-pressure flow applications. It is brass, which offers good corrosion resistance. Pipe is seamless and has a smooth interior for unrestricted flow.

Fully threaded pipe is also known as a close nipple; it is threaded on each end to the center.

To adhere to safety standards for drinking water systems, use pipe that meets NSF/ANSI 61.

For technical drawings and 3-D models, click on a part number.

- For Use With:

Lengths 6" and Shorter: Air, Natural Gas, Oil, Steam, Water

Lengths 12" and Longer: Air, Drinking Water, Natural Gas, Oil, Steam, Water - Specifications Met:

Lengths 6" and Shorter: ASME BS21, ASTM B687

Lengths 12" and Longer: ASME BS21, ASTM B687, NSF/ANSI 61 - Fittings: Use Class 125 brass or bronze

- Flanges: Use Class 150 brass or bronze

- For Use With:

Lengths 1 1/2" and Shorter: Air, Natural Gas, Oil, Steam, Water

Lengths 1 5/8" and Longer: Air, Drinking Water, Natural Gas, Oil, Steam, Water - Specifications Met:

Lengths 1 1/2" and Shorter: ASME B1.20.1, ASME BS21, ASTM B687

Lengths 1 5/8" and Longer: ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 - Fittings: Use Class 125 brass or bronze

- Flanges: Use Class 150 brass or bronze

| Pipe Size | Lg. | Construction | Each | |

| 1 1/2 | 1 3/4" | Seamless | 00000000 | 000000 |

- For Use With: See Table

- Specifications Met: See Table

- Fittings: Use Class 125 brass or bronze

- Flanges: Use Class 150 brass or bronze

| Lg. | Construction | For Use With | Specifications Met | Each | |

1 1/2 Pipe Size | |||||

|---|---|---|---|---|---|

| 2" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 000000 |

| 3" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 00000 |

| 4" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 00000 |

| 6" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 00000 |

| 12" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 000000 |

| 36" | Seamless | Air, Drinking Water, Natural Gas, Oil, Steam, Water | ASME B1.20.1, ASME BS21, ASTM B687, NSF/ANSI 61 | 00000000 | 000000 |

Standard-Wall Brass Threaded Pipe Nipple and Pipe Assortments

- For Use With: Air, Drinking Water, Natural Gas, Oil, Steam, Water

- Specifications Met: ASME B1.20.1, ASTM B687, Fed. Spec. WW-N-351C, NSF/ANSI 61

- For Fitting Class: 125

Keep various lengths of brass pipe on hand for applications requiring good corrosion resistance. The pipe in these assortments is threaded, so you can take apart its connections for maintenance and repair. They’re Schedule 40, so they should be used in low-pressure applications. This pipe is seamless, so it has a smooth interior for unrestricted flow, and it’s stronger than welded pipe.

Fully threaded pipe nipples are also known as a close nipple; they are threaded on each end to the center.

| Pipe Size | No. of Pieces | Includes | Material | Each | |

NPT Male | |||||

|---|---|---|---|---|---|

| 1 1/2 | 25 | 5 fully threaded 1 3/4" Lg. nipples 20 threaded-on-both-ends nipples in the following lengths: 2” (5 ea.), 2 1/2” (3 ea.), 3” (2 ea.), 3 1/2” (2 ea.), 4” (2 ea.), 4 1/2” (1 ea.), 5” (2 ea.), 5 1/2” (1 ea.), 6" (2 ea.) | 230 Brass | 0000000 | 0000000 |

Standard-Wall Brass Unthreaded Pipe

- For Use With: Air, Natural Gas, Oil, Steam, Water

- Specifications Met: ASTM B43

With two unthreaded ends, this pipe is designed for brazed connections, which are stronger than threaded connections and less likely to leak. It is also known as Schedule 40. Pipe is seamless, so it has a smooth interior for unrestricted flow. It is brass, which has good corrosion resistance.

Fiberglass Pipe for Corrosive Chemicals

- For Use With: Acetic Acid (75%), Alcohol, Calcium Chloride, Chlorine, Fuel Oil, Gasoline, Hydrochloric Acid (37%), Nitric Acid (10%), Oil, Phosphoric Acid, Salt Water (30%), Sodium Hydroxide (50%), Sulfuric Acid (70%), Water

- Temperature Range: 32° to 200° F

- Specifications Met: ASTM D2310, ASTM D3567

With excellent corrosion resistance, this pipe can handle a wide range of acids and other highly-corrosive chemicals. Use in metal surface treating applications, plating solution lines, and other chemical process applications. Layers of fiberglass give this pipe better strength and durability than any of our other pipe for chemicals. Pipe meets ASTM D2310 and ASTM D3567 specifications and testing requirements for product dimensions, performance, and material quality.

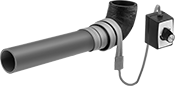

To connect fittings to pipe, first sand the inside of the fitting and the end of the pipe to remove the surface finish. Next, mix the adhesive (sold separately) until the color is uniform with no streaks. Apply a thin layer of mixed adhesive to the sanded area of the pipe, approximately 1/8” thick. Repeat this process with the inside of the fitting, applying a layer approximately 1/16” thick. After sealant has been applied, push the fitting onto the pipe until it is fully engaged. Finally, use the adhesive-curing heat cable (sold separately) to cure the adhesive. Wrap the tape around the pipe and fitting at the joint, taking care to not overlap the tape. Once you have waited the full cure time, the pipe and fitting will be ready to use.

Warning: Never use plastic pipe fittings and pipe with compressed air or gas.

| Voltage | Current | Max. Heat Output, °F | Lg. | Wd. | Thick. | Plug Type | Cord Lg. | Each | |

| 120V AC | 15 A | 270° | 6 ft. | 1" | 1/8" | Two Prong | 6 ft. | 0000000 | 0000000 |

Continuous-Flex Liquid-Tight Plastic Conduit

Also known as Type A, this conduit meets the demands of continuous motion while sealing out liquid when used with liquid-tight fittings. A layer of nylon provides strength during flexing. This conduit is crush and abrasion resistant as well as flame retardant. It also resists oil, chemicals, and UV light.

One end twists into a piece of conduit for a quick connection; the other end attaches to a knockout in an outlet box or enclosure. These fittings seal out liquid when used with continuous-flex liquid-tight plastic conduit.

Steel fittings are stronger than acetal.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Conduit Connection Type | Gender | Pipe Size | Thread Type | Gender | Each | |

Steel | |||||||

| 1 1/2 | Twist-In | Female | 1 1/2 | NPT | Male | 0000000 | 0000000 |

One end twists into a piece of conduit for a quick connection; the other end attaches to a knockout in an outlet box or enclosure. These fittings seal out liquid when used with continuous-flex liquid-tight plastic conduit.

Steel fittings are stronger than acetal.

Conduit Connection | Electrical Box Connection | ||||||

|---|---|---|---|---|---|---|---|

| Conduit Trade Size | Conduit Connection Type | Gender | Pipe Size | Thread Type | Gender | Each | |

Steel | |||||||

| 1 1/2 | Twist-In | Female | 1 1/2 | NPT | Male | 0000000 | 0000000 |