About Metal Tubing

More

Welded Stainless Steel Tubing

When your application does not require a smooth interior, this tubing is an economical choice. It has a weld bead on the inside.

304 stainless steel has very good corrosion resistance.

316 stainless steel offers excellent corrosion resistance.

- Temperature Range: 304 Stainless Steel: -420° to 1500° F

316 Stainless Steel: -320° to 1500° F - Bending Method: Tube Bender

- Compatible Tube Fittings: See table

| OD | Wall Thickness | ID | Maximum Pressure | Temper Rating | Compatible Tube Fittings | 1 ft. | 3 ft. | 6 ft. | |

304 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| 4" | 0.065" | 3.87" | 540 psi @ 72° F | Soft | Butt Weld, Compression | 00000000 | |||

316 Stainless Steel—For Use With Air, Deionized Water, Hydraulic Fluid, Natural Gas, Oil, Water | |||||||||

| 4" | 0.065" | 3.87" | 540 psi @ 72° F | Soft | Butt Weld, Compression | 000000000 | |||

Vacuum-Rated Large-Diameter Aluminum Tubing

- Temperature Range: Not Rated

- Bending Method: Tube Bender

- Compatible Fittings: Vacuum

Move bulk material, exhaust gas, or suck up dust in powerful vacuum systems—this tubing is large enough to transfer pellets and debris and strong enough to withstand nearly perfect vacuum. Made of aluminum, it’s lighter weight than steel tubing, so it’s best when you need to reduce the weight of your system. It also resists corrosion from frequent rinsing, humidity, and rain. Nonmagnetic, it won’t disrupt sensitive equipment. This tubing isn’t welded, which means it’s free of weak spots and ridges that could obstruct flow.

Vacuum-Rated Large-Diameter Steel Tubing

- Max. Temperature: Not Rated

- Bending Method: Tube Bender

- Compatible Fittings: Vacuum

This tubing has the strength to withstand vacuum applications up to 29" Hg. It is welded and has a weld bead on the inside.

Tubing with a galvanized finish offers better corrosion resistance than unfinished steel.

Low-Carbon Steel Round Tubes

Also known as mild steel, low-carbon steel is easy to machine, form, and weld. It's widely fabricated into parts that don’t require high strength, such as frames, supports, and conduit. This steel is manufactured to ASTM, SAE, or EN standards for quality and performance.

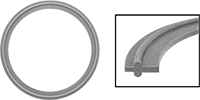

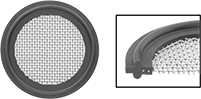

Ultra-Chemical-Resistant Metal-Detectable

PTFE Gaskets for Quick-Clamp Tube Fittings

If a piece wears off, fragments as small as 1 mm can be picked up by a metal-detection system to prevent contamination of your process line. These gaskets are made from a blend of PTFE and stainless steel, which is chemically inert (except to molten alkali metal and elemental fluorine). The construction also allows them to maintain their strength in steam and hot oil applications.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.203" | -325° to 550° | Durometer 68D | Extra Hard | Gray | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 0000000 | 000000 |

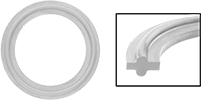

Ultra-Chemical-Resistant PTFE Gaskets for Quick-Clamp Tube Fittings

Made of PTFE, these gaskets are chemically inert (except to molten alkali metal and elemental fluorine). They ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.18" | -100° to 500° | Durometer 63D | Extra Hard | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550 | 00000000 | 00000 |

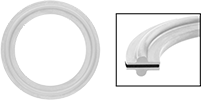

EPDM-Filled Ultra-Chemical-Resistant PTFE

Gaskets for Quick-Clamp Tube Fittings

Made from PTFE with an EPDM core, these gaskets have added resiliency resulting in a longer product life. They are chemically inert (except to molten alkali metal and elemental fluorine) and ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.185" | -30° to 300° | Durometer 68D | Extra Hard | White | 3-A Certified 20-27, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

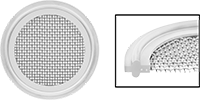

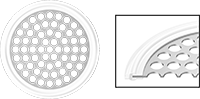

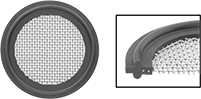

Ultra-Chemical-Resistant PTFE Gaskets

with Screen for Quick-Clamp Tube Fittings

Offering excellent resistance to detergents, hydraulic fluid, and salts, these PTFE gaskets have a corrosion-resistant 316 stainless steel screen to provide inline straining. They also have good resistance to most acids and alkalies. Use them to ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. The mesh size indicates the number of openings on the screen per square inch.

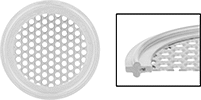

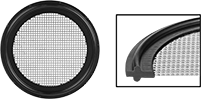

Ultra-Chemical-Resistant PTFE Gaskets with

Perforations for Quick-Clamp Tube Fittings

These chemical-resistant gaskets have a perforated plate that filters, separates, and strains liquids or dry materials in your line. Made of 316 stainless steel, the plate won’t corrode from frequent washdowns with harsh cleaners. Gaskets are made of PTFE for excellent resistance to detergents, hydraulic fluid, and salts, and good resistance to most acids and alkalis. They create tight seals in quick-clamp sanitary tube fittings. These gaskets are 3-A certified for sanitary design and are FDA compliant for direct contact with food. They meet ASME BPE purity and safety standards, and are rated USP Class VI as plastic that won’t leach into biological samples.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Color | Specifications Met | Each | |

Straight Holes | ||||||||

|---|---|---|---|---|---|---|---|---|

0.033" Hole Diameter | ||||||||

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 0000000 |

Staggered Holes | ||||||||

1/16" Hole Diameter | ||||||||

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/8" Hole Diameter | ||||||||

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/4" Hole Diameter | ||||||||

| 4" | 3.870" | 4.680" | 0.185" | -100° to 500° | Clear | 3-A Certified 20-27, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

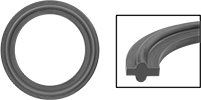

Chemical-Resistant Fluoroelastomer Gaskets for Quick-Clamp Tube Fittings

Resistant to fuel, oil, and acid condensates, these gaskets are made of fluoroelastomer. They ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.203" | -15° to 400° | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Chemical-Resistant Fluoroelastomer Gaskets

with Screen for Quick-Clamp Tube Fittings

In addition to providing a tight seal in quick-clamp stainless steel sanitary tube fittings, these gaskets have a corrosion-resistant 316 stainless steel screen to provide inline straining. They resist fuel, oil, and acid condensates. The mesh size indicates the number of openings on the screen per square inch.

High-Temperature Silicone Gaskets for Quick-Clamp Tube Fittings

Even as temperatures rise, these silicone gaskets ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. They withstand temperatures up to 450° F. These gaskets also resist water and salts.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.203" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

High-Temperature Metal-Detectable Silicone

Gaskets for Quick-Clamp Tube Fittings

If a piece wears off, fragments as small as 1 mm can be picked up by a metal-detection system to prevent contamination of your process line. These gaskets are silicone and withstand temperatures up to 390° F; they also resist water and salts. They ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.2" | -70° to 390° | Durometer 70A | Hard | Blue | 3-A Certified 18-03, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

High-Temperature Silicone Gaskets with

Perforations for Quick-Clamp Tube Fittings

Use these perforated gaskets to filter liquids and dry materials, as well as create a tight seal in quick-clamp stainless steel sanitary tube fittings. Made of silicone, they handle temperatures up to 450° F, so they’re good for heated ingredients and clean-in-place (CIP) processes. However, oils will degrade them. Their perforated plate is 316 stainless steel to withstand washdowns with harsh cleaners and sanitizers. All of these gaskets are 3-A certified to meet sanitary design standards and FDA compliant for direct contact with food. USP Class VI, they’ve been tested to the highest standards to reduce the risk of leaching into biological samples. They also meet ASME BPE, which is a design standard for bioprocessing equipment that helps ensure purity and safety.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

Staggered Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

1/4" Hole Diameter | ||||||||||

| 4" | 3.870" | 4.680" | 0.185" | -40° to 450° | Durometer 80A | Hard | Clear | 3-A Certified 18-03, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 0000000 |

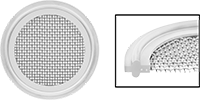

High-Temperature Silicone Gaskets with Screen for Quick-Clamp Tube Fittings

A corrosion-resistant 316 stainless steel screen provides inline straining. These silicone gaskets withstand temperatures up to 450° F. Use them to ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. The mesh size indicates the number of openings on the screen per square inch.

Water- and Steam-Resistant EPDM Gaskets for Quick-Clamp Tube Fittings

When working in moist environments, these EPDM gaskets ensure a tight seal in quick-clamp stainless steel sanitary tube fittings.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.203" | -20° to 300° | Durometer 70A | Hard | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |

Water- and Steam-Resistant EPDM Gaskets

with Screen for Quick-Clamp Tube Fittings

The built-in screen is made of corrosion-resistant 316 stainless steel and provides inline straining. Use these EPDM gaskets in moist environments. They ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. The mesh size indicates the number of openings on the screen per square inch.

Water- and Steam-Resistant EPDM Gaskets

with Perforations for Quick-Clamp Tube Fittings

These gaskets have a perforated plate to filter, separate, and strain liquids or dry materials in your line. Made of 316 stainless steel, the plate won’t corrode from frequent washdowns with harsh cleaners. Neither will the rest of these gaskets, which are made of EPDM rubber that resists water, steam, and UV light. In addition to filtering, they ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. Gaskets are FDA compliant for direct contact with food and 3-A certified as meeting sanitary design standards. They meet ASME BPE purity and safety standards for bioprocessing equipment, and are rated USP Class VI as made from plastic that won’t contaminate biological samples.

| For Tube OD | ID | OD | Thickness | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

Straight Holes | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

0.033" Hole Diameter | ||||||||||

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 0000000 |

Staggered Holes | ||||||||||

1/16" Hole Diameter | ||||||||||

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/8" Hole Diameter | ||||||||||

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

1/4" Hole Diameter | ||||||||||

| 4" | 3.870" | 4.680" | 0.185" | -30° to 400° | Durometer 70A | Hard | Black | 3-A Certified 62-02, ASME BPE, FDA Compliant 21 CFR 177.2600, USP Class VI | 0000000 | 000000 |

Oil-Resistant Buna-N Gaskets for Quick-Clamp Tube Fittings

These Buna-N gaskets ensure a tight seal in quick-clamp stainless steel sanitary tube fittings. They resist oil and water.

| For Tube OD | ID | OD | Thick. | Temperature Range, °F | Hardness | Hardness Rating | Color | Specifications Met | Each | |

| 4" | 3.87" | 4.68" | 0.203" | -30° to 200° | Durometer 70A | Hard | Black | 3-A Certified 18-03, FDA Compliant 21 CFR 177.1550, FDA Compliant 21 CFR 177.2600 | 0000000 | 00000 |