Compare over 50 grades of steel and cast iron to find the right material for you—all with material certificates for traceability.

About Shafts

More

Multipurpose 4140 Alloy Steel Round Tubes

- Yield Strength: 60,000 psi

- Hardness: Rockwell B85 (Medium)

- Heat Treatable: Yes

- Max. Hardness After Heat Treatment: Rockwell C60

- Fabrication: Seamless

- Specifications Met: ASTM A519

Made from alloy steel, also known as chrome-moly steel, these tubes resist fracturing from repeated stress. They’re used for a wide range of parts, including cylinders, rollers, and frames. For added wear resistance, they can be surface hardened with heat treating. These tubes have been manufactured to meet ASTM standards for quality and performance.

Note: Tubes may be made from either 4140 or 4142 alloy steel. They are interchangeable in most applications.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| OD | ID | Heat Treatment | Straightness Tolerance | 1/2 ft. Lg. | 1 ft. Lg. | 3 ft. Lg. | 4 ft. Lg. | 6 ft. Lg. | 8 ft. Lg. | |

1/2" Wall Thick. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 2 1/2" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 2 3/4" | 1 3/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 3" | 2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 3 1/4" | 2 1/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 3 3/4" | 2 3/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 4" | 3" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 5" | 4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

5/8" Wall Thick. | ||||||||||

| 3 1/4" | 2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 4" | 2 3/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

3/4" Wall Thick. | ||||||||||

| 3" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 3 1/4" | 1 3/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 3 1/2" | 2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 3 3/4" | 2 1/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 4" | 2 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 4 1/4" | 2 3/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 4 1/2" | 3" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 4 3/4" | 3 1/4" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 5" | 3 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 6" | 4 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

1" Wall Thick. | ||||||||||

| 3 1/2" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 4" | 2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 4 1/2" | 2 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 5" | 3" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 5 1/2" | 3 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 6" | 4" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 6 1/2" | 4 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 7" | 5" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 8" | 6" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

1 1/4" Wall Thick. | ||||||||||

| 4 1/2" | 2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 5" | 2 1/2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 5 1/2" | 3" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

2" Wall Thick. | ||||||||||

| 6" | 2" | Annealed (Softened) | 0.030" per ft. | 0000000 | ||||||

| 8" | 4" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 10" | 6" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

| 12" | 8" | Annealed (Softened) | 0.030" per ft. | 00000000 | ||||||

3" Lg. | |||||

|---|---|---|---|---|---|

| OD | ID | Heat Treatment | Straightness Tolerance | Each | |

1/2" Wall Thick. | |||||

| 2 1/2" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | 000000 |

| 2 3/4" | 1 3/4" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

| 3" | 2" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

| 3 3/4" | 2 3/4" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

3/4" Wall Thick. | |||||

| 3" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

| 4 3/4" | 3 1/4" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

1" Wall Thick. | |||||

| 3 1/2" | 1 1/2" | Annealed (Softened) | 0.030" per ft. | 00000000 | 00000 |

Rotary Shafts

Combine these general purpose drive shafts with gears, sprockets, and bearings to transmit rotary motion. All are turned, precision ground, and polished to meet tight diameter and straightness tolerances. This means these shafts evenly distribute loads, reduce vibration, and improve accuracy and stability.

Steel shafts are generally stronger than stainless steel shafts but not as corrosion resistant. Alloy steel shafts are good for high-stress applications. They are stronger than carbon steel and hardened for increased wear resistance; however, they are more difficult to machine.

Shafts with chamfered edges reduce damage to bearings, housings, and other components during installation.

| Lg. | Lg. Tolerance | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—4140 Alloy Steel | |||||||

|---|---|---|---|---|---|---|---|

1/4" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

3/8" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

1/2" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

5/8" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

3/4" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

1" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

1 1/4" Dia. (Tolerance: -0.001" to 0") | |||||||

| 6" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 12" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 36" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

| 72" | 0" to 0.005" | 0.0125" per ft. | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

Metric—4140 Alloy Steel | |||||||

10mm Dia. (Tolerance: -0.025mm to 0mm) | |||||||

| 152mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 305mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 914mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

| 1,829mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

12mm Dia. (Tolerance: -0.025mm to 0mm) | |||||||

| 152mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 305mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 914mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 1,829mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

20mm Dia. (Tolerance: -0.025mm to 0mm) | |||||||

| 152mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 305mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 914mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 1,829mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

25mm Dia. (Tolerance: -0.025mm to 0mm) | |||||||

| 152mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 305mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 000000 | 00000 |

| 914mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 00000 |

| 1,829mm | 0" to 0.005" | 0.3 mm per 300 mm | Chamfered | Hard | Rockwell C28 | 0000000 | 000000 |

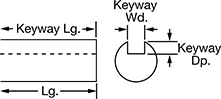

Keyed Rotary Shafts

Combine these shafts with a machine key (not included) to transmit torque to gears, sprockets, and other power transmission components. All have an ANSI standard keyway (keys not included; see our selection of key stock). Their edges are chamfered to remove sharp corners, reducing damage to bearings, housings, and other components during installation. All are turned, ground, or polished to tight diameter and straightness tolerances.

Steel shafts are generally stronger than aluminum and stainless steel shafts but not as corrosion resistant. 4140 alloy steel shafts are good for high-stress applications. They are stronger than carbon steel and hardened for increased wear resistance; however, they are more difficult to machine.

Keyway | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Lg. | Lg. | Wd. | Dp. | ANSI Keys Included | Straightness Tolerance | Edge Type | Hardness Rating | Hardness | Each | |

Inch—4140 Alloy Steel | ||||||||||

3/4" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 12" | 12" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 000000 |

| 36" | 36" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 00000 |

| 72" | 72" | 0.188" | 3/32" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 000000 |

1" Dia. (Tolerance: -0.0025" to 0") | ||||||||||

| 12" | 12" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 00000 |

| 36" | 36" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 00000 |

| 72" | 72" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 000000 |

1 1/4" Dia. (Tolerance: -0.003" to 0") | ||||||||||

| 12" | 12" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 00000 |

| 36" | 36" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 000000 |

| 72" | 72" | 0.25" | 1/8" | No | 0.013" per ft. | Chamfered | Medium | Rockwell B98 | 000000 | 000000 |