Filter by

Media Treatment

Tumbler Motion

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Tumbling Media for Steel, Stainless Steel, and Hard Metals

5 lb. | 10 lb. | 25 lb. | 50 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Dia., mm | Density, lb/ft³ | Recommended Media to Parts Ratio | Abrasion Type | Tumbling Condition | Material | Pkg. | Pkg. | Pkg. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

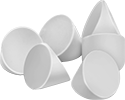

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 7/16" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/16" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 000000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/16" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | — | 90 | 3:1 | Heavy | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Extra-Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 7/16" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/16" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/16" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | — | 90 | 3:1 | Medium | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Ultra Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 7/16" | — | 90 | 3:1 | Light | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | — | 90 | 3:1 | Light | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | — | 90 | 3:1 | Light | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | — | 90 | 3:1 | Light | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 00000000 | 000000 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Polished Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7/16" | 7/16" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/16" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 5/16" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 3/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 3/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16" | 7/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 3/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8" | 5/8" | — | 90 | 3:1 | None | Wet | Ceramic | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Mirror Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 mm | 1 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 mm | 2 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 mm | 3 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 mm | 3 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 14 mm | 5 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 23 mm | 7 mm | — | 140 | 3:1 | None | Wet | Porcelain | 0000000 | 000000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

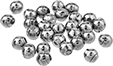

Ball | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 1 | 125 | 3:1 | None | Wet | Porcelain | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 2 | 125 | 3:1 | None | Wet | Porcelain | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 3 | 125 | 3:1 | None | Wet | Porcelain | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 4 | 125 | 3:1 | None | Wet | Porcelain | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 6 | 125 | 3:1 | None | Wet | Porcelain | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tumbling Media for Aluminum, Brass, and Soft Metals

5 lb. | 10 lb. | 15 lb. | 25 lb. | 50 lb. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Density, lb/ft³ | Recommended Media to Parts Ratio | Abrasion Type | Tumbling Condition | Material | Pkg. | Pkg. | Pkg. | Pkg. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Extra-Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

V-Cylinder | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 000000 | 00000000 | 0000000 | ——— | 0 | 00000000 | 0000000 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/4" | 3/4" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Triangle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/8" | 1/2" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

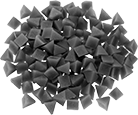

Pyramid | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/4" | 1/4" | 60 | 3:1 | Medium | Wet | Plastic | 00000000 | 00000 | 00000000 | 000000 | ——— | 0 | 00000000 | 000000 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Ultra Smooth Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

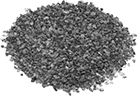

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 40 | 4:1 | None | Dry | Walnut Shell | ——— | 0 | 0000000 | 00000 | ——— | 0 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Polished Finish | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Granule | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| — | — | 32 | 4:1 | None | Dry | Corn Cob | ——— | 0 | ——— | 0 | 00000000 | 000000 | ——— | 0 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||