Filter by

Material

Ball Material

Diameter

Shape

Tolerance Rating

Hardness Rating

Density

Hardness

Mechanical Finish

Appearance

Yield Strength

Minimum Temperature

Performance

Maximum Temperature

Temper Rating

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Container Type

Ultra-Hard C2 Tungsten Carbide

Balls

Dia. | Dia. Tolerance | Mechanical Finish | Yield Strength | Hardness | Temper Rating | Pkg. Qty. | Pkg. | |||

|---|---|---|---|---|---|---|---|---|---|---|

| 3/64" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 00000 | ||

| 1/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 0000 | ||

| 5/64" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 00000 | ||

| 3/32" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 0000 | ||

| 7/64" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 00000 | ||

| 1/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 00000 | ||

| 5/32" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 0000 | ||

| 3/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 000000 | 0000 | ||

| 7/32" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 0000 | ||

| 1/4" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 0000 | ||

| 9/32" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 5/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 11/32" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 3/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 7/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 1/2" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 000000 | 00000 | ||

| 9/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 5/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 3/4" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 13/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 7/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 000000 | ||

| 15/16" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 000000 | ||

| 1" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 000000 | ||

| 1 1/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 00000000 | 000000 | ||

| 1 1/4" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 00000000 | 000000 | ||

| 1 3/8" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 00000000 | 000000 | ||

| 1 1/2" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 00000000 | 000000 | ||

| 2" | -0.0001" to 0.0001" | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 00000000 | 000000 | ||

| 1 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 0000 | ||

| 2 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 00000 | ||

| 3 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 5 | 0000000 | 0000 | ||

| 4 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 5 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 0000 | ||

| 6 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 0000 | ||

| 7 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 8 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 2 | 0000000 | 00000 | ||

| 10 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 12 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 13 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 14 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

| 15 mm | -0.0025 mm to 0.0025 mm | Polished | Not Rated | Rockwell C75 (Extra Hard) | Not Rated | 1 | 0000000 | 00000 | ||

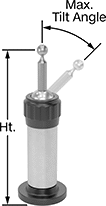

Calibration Spheres for CMMs

Ball | Base | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia., mm | Sphericity Tolerance, mm | Dia. Tolerance, mm | Material | Ht., mm | Dia., mm | Material | Rotation | Max. Tilt Angle | Certificate Type | Container Type | Each | ||

| 12 | -0.0001 to 0.0001 | -0.001 to 0.001 | Tungsten Carbide | 156 to 173 | 57 | Aluminum | 360° | 45° | Calibration Certificate with Test Data Traceable to UKAS | Plastic Case | 0000000 | 0000000 | |

| 25 | -0.0001 to 0.0001 | -0.001 to 0.001 | Tungsten Carbide | 156 to 173 | 57 | Aluminum | 360° | 45° | Calibration Certificate with Test Data Traceable to UKAS | Plastic Case | 0000000 | 000000 | |