About On/Off Valves

More

About Actuated On/Off Valves

More

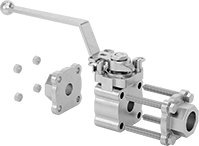

Socket-Connect On/Off Valves for Fuel

- Valve Type: Ball

- For Use With: Diesel Fuel, Fuel Oil, Gasoline, Kerosene

- Seal Material: Glass-Filled PTFE Plastic

- Specifications Met: American Petroleum Institute Standard 598, American Petroleum Institute Standard 607 - Edition 6, American Petroleum Institute Standard 608 - Edition 6, American Petroleum Institute Standard 641, ASME B16.11, ASME B16.34, MSS-SP 72, NACE (National Association of Corrosion Engineers) MR0175

Install these valves to start and stop the flow of diesel fuel, fuel oil, kerosene, and gasoline. Fire-tested to meet American Petroleum Institute (API) 607, these valves are designed to securely isolate fluid and prevent the spread of fire. They have also passed fugitive emissions testing and meet API 641 standards to reduce the risk of hazardous gas leaks.

Insert unthreaded pipe into the socket ends and weld to create a permanent, leak-tight connection to your pipeline. To service these valves, unbolt the three-piece body. You can then access the internal components without cutting the welded connection. These valves have a lockable handle that can be secured using a padlock (not included). All are full port, so they do not restrict flow.

316 stainless steel valves are more corrosion resistant than steel valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | End-to-End Lg. | For Max. Shackle Dia. | Each | |

Steel Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | ||||||||

| 1/4 | Any | 8 | 1970 psi @ 100° F | -20° to 400° | 2 15/16" | 5/16" | 0000000 | 000000 |

| 1/2 | Any | 12 | 1970 psi @ 100° F | -20° to 400° | 3 1/16" | 5/16" | 0000000 | 000000 |

| 3/4 | Any | 32 | 1970 psi @ 100° F | -20° to 400° | 3 3/4" | 5/16" | 0000000 | 000000 |

| 1 | Any | 46 | 1970 psi @ 100° F | -20° to 400° | 4 1/4" | 5/16" | 0000000 | 000000 |

| 2 | Any | 240 | 1970 psi @ 100° F | -20° to 400° | 6 5/16" | 3/8" | 0000000 | 000000 |

316 Stainless Steel Body | ||||||||

Socket Connect × Socket Connect | ||||||||

| 1/4 | Any | 8 | 1920 psi @ 100° F | -20° to 400° | 2 15/16" | 5/16" | 0000000 | 000000 |

| 1/2 | Any | 12 | 1920 psi @ 100° F | -20° to 400° | 3 1/16" | 5/16" | 0000000 | 000000 |

| 3/4 | Any | 32 | 1920 psi @ 100° F | -20° to 400° | 3 3/4" | 5/16" | 0000000 | 000000 |

| 1 | Any | 46 | 1920 psi @ 100° F | -20° to 400° | 4 1/4" | 5/16" | 0000000 | 000000 |

| 2 | Any | 240 | 1920 psi @ 100° F | -20° to 400° | 6 5/16" | 3/8" | 0000000 | 00000000 |

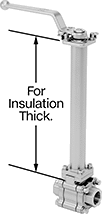

Socket-Connect On/Off Valves for Cryogenic Liquids

- Valve Type: Ball

- For Use With: Liquid Argon, Liquid Carbon Dioxide, Liquid Nitrogen

- Seal Material: Graphite

- Specifications Met: American Petroleum Institute Standard 607 - Edition 7

Designed to withstand extremely cold liquid gases, these valves are ideal for liquid nitrogen cooling systems and liquified gas storage. They have PCTFE seats that maintain a tight seal at temperatures as low as -400° F. A vented ball relieves internal gas and pressure build-up from frequent temperature fluctuations during use. These valves have an insulated, extra-long stem to prevent heat transfer and leaks. The extended stem keeps the handle at a comfortable temperature and your hands away from hazards, so you can start and stop flow even in hard-to-reach areas. To maintain performance and safety, these valves are shipped cleaned and bagged to avoid contamination.

Insert unthreaded pipe into the socket ends and weld to create a permanent, leak-tight connection. All are full port, so they do not restrict flow. To prevent changes, add a padlock to fix the handle in place.

Fire-tested to meet American Petroleum Institute (API) 607, these valves securely isolate flammable substances to prevent the spread of fire.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | For Pipe Schedule | Flow Coefficient (Cv) | Max. Pressure | Min. Temperature, °F | End-to-End Lg. | For Insulation Thick. | For Max. Shackle Dia. | Features | Each | |

316 Stainless Steel Body | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

Socket Connect × Socket Connect | ||||||||||

| 3/4 | Any | 32 | 1440 psi @ 100° F | -400° | 3 3/4" | 10 7/8" | 5/16" | Vented Ball | 0000000 | 000000000 |

| 1 | Any | 46 | 1440 psi @ 100° F | -400° | 4 1/4" | 10 13/16" | 5/16" | Vented Ball | 0000000 | 00000000 |

| 2 | Any | 240 | 1440 psi @ 100° F | -400° | 6 5/16" | 11 7/8" | 3/8" | Vented Ball | 0000000 | 00000000 |

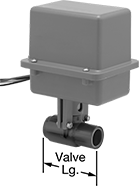

Motor-Driven On/Off Valves with Socket-Connect Fittings for Drinking Water

- Valve Type: Ball

- For Use With: Drinking Water

- Seal Material: EPDM Rubber

- Specifications Met: NSF/ANSI 61

Insert unthreaded pipe into the socket ends and bond with PVC primer and cement to create a permanent, leak-tight connection. These valves meet NSF/ANSI Standard 61 for drinking water applications. All operate on electricity to automatically start and stop flow. Valves don’t require a minimum pressure drop between the inlet and outlet for operation. They are normally closed unless actuated. All valves are full port, so they do not restrict flow.

The actuator is directly mounted to the valve body to minimize movement and reduce wear. Valves meet NEMA 4X for resistance to washdowns, splashing water, corrosive liquid, and dust.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

Overall | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Actuation Time, sec. | Temp. Range, °F | Valve Lg. | Lg. | Ht. | Environmental Rating | Each | |

Dark Gray PVC Plastic Body with Wire Leads | ||||||||||||

Normally Closed—120V AC | ||||||||||||

| 1/2 | Female | 42 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 3 1/16" | 5 3/8" | 7 3/8" | NEMA 4X | 0000000 | 0000000 |

| 3/4 | Female | 87 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 3 9/16" | 5 3/8" | 7 13/16" | NEMA 4X | 0000000 | 000000 |

| 1 | Female | 157 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 4" | 5 3/8" | 8 1/8" | NEMA 4X | 0000000 | 000000 |

| 1 1/4 | Female | 311 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 4 5/8" | 6 1/16" | 8 15/16" | NEMA 4X | 0000000 | 000000 |

| 1 1/2 | Female | 429 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 5 1/4" | 6 1/16" | 9 3/8" | NEMA 4X | 0000000 | 000000 |

| 2 | Female | 768 | 235 psi @ 100° F | Zero Pressure Drop | 5 | 40° to 140° | 6" | 6 1/16" | 10 3/16" | NEMA 4X | 0000000 | 000000 |