About Backflow-Prevention Valves

More

About Actuated On/Off Valves

More

About On/Off Valves

More

Miniature Threaded On/Off Valves for Chemicals

- Valve Type: Ball

- For Use With: Air, Argon, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethylene Glycol, Fuel Oil, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hydroxide, Sodium Hypochlorite, Sulfuric Acid, Toluene, Water, Xenon, Xylene

- Ball Material: 316 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

- Seat Material: Fluoroelastomer Rubber

To withstand aggressive and corrosive solutions in miniature chemical-processing pipelines, these tiny valves have a chemical-resistant fluoroelastomer seal and a corrosion-resistant 303 stainless steel body. They are standard port, so they slightly restrict flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Thread Size | Flow Coefficient (Cv) | Max. Pressure | Temperature Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

303 Stainless Steel Body | |||||||

|---|---|---|---|---|---|---|---|

UNF Female × UNF Female | |||||||

| 10-32 | 0.1 | 250 psi @ 150° F | 0° to 400° | 25 | 11/16" | 0000000 | 0000000 |

On/Off Valves with Barbed Fittings for Chemicals

Barbs grip onto tubing, providing a secure hold. To withstand aggressive and corrosive solutions in chemical-processing applications, these valves have a plastic body and a chemical-resistant seal.

PVDF valves have excellent chemical resistance. They withstand a variety of acids, solvents, and other harsh substances.

Four-arm handles have a mounting tab to securely align the valve with connecting lines. They’re ideal for systems prone to vibration that can cause movement and leaks.

Full-port valves do not restrict flow.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions

- Ball Material: PVDF Plastic

- Seal Material: PVDF Plastic

- Seat Material: PVDF Plastic

| For Tube ID | Max. Pressure | Temperature Range, °F | Port Type | End-to-End Lg. | Features | Each | |

Standard Barbed × Standard Barbed | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | 15 psi @ 65° F | 35° to 100° | Full | 2 1/8" | With Mounting Tab | 00000000 | 000000 |

| 5/16" | 15 psi @ 65° F | 35° to 100° | Full | 2 1/8" | With Mounting Tab | 00000000 | 00000 |

| 3/8" | 15 psi @ 65° F | 35° to 100° | Full | 2 3/4" | With Mounting Tab | 00000000 | 00000 |

| 7/16" | 15 psi @ 65° F | 35° to 100° | Full | 2 3/4" | With Mounting Tab | 00000000 | 00000 |

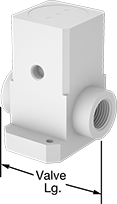

Severe-Duty Air-Driven On/Off Valves for Chemicals

- Valve Type: Diaphragm

- For Use With:

Pipe Size 1/4: Oil, Air, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Sodium Hypochlorite, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide

Pipe Size 1/2: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide

Pipe Size 3/4: Water, Oil, Air, Natural Gas, Propane, Butane, Acetone, Ammonia, Carbon Dioxide, Chlorine, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Nitric Acid, Nitrogen, Oxygen, Salt Water, Soap Solutions, Sodium Hypochlorite, Steam, Sulfuric Acid, Toluene, Citric Acid, Phosphoric Acid, Sodium Hydroxide - Seal Material : PTFE Plastic

- Seat Material: PTFE Plastic

- Actuator Housing Material: Plastic

Also known as diaphragm valves, these have a PTFE body and seals that stand up to harsh acidic solutions. The diaphragm can handle dirty liquid, slurries, and abrasive media without damage. All valves operate on compressed air to automatically start and stop flow. You must control the air to the actuator using either an electric pilot valve (not included) or a manual on/off valve (not included). These valves don’t require a minimum pressure drop between the inlet and outlet for operation.

All have a single-acting actuator that only requires air pressure to open the valve; they automatically spring closed when the air turns off. The actuator is directly mounted to the valve body to minimize movement and reduce wear. Valves are normally closed unless actuated.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Air | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Gender | Thread Type | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Temp. Range, °F | Valve Lg. | O'all Ht. | Connection | Pressure Range, psi | Mounting Stud Screw Size | No. of Mounting Studs | Fasteners Included | Each | |

PTFE Plastic Body | |||||||||||||||

Single Acting: Air-to-Open, Spring Return (Normally Closed) | |||||||||||||||

| 1/4 | Female | NPT | 0.7 | 60 psi @ 140° F | Zero Pressure Drop | 35° to 175° | 2 1/8" | 2 7/8" | 1/8 NPT Female | 40 to 60 | __ | 2 | No | 00000000 | 0000000 |

| 1/2 | Female | NPT | 2.8 | 60 psi @ 140° F | Zero Pressure Drop | 35° to 210° | 2 3/4" | 3 3/8" | 1/8 NPT Female | 60 to 80 | 1/4" | 2 | No | 00000000 | 000000 |

| 120V AC Pilot Valve | 00000000 | Each | 0000000 |

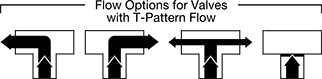

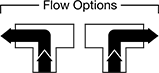

Diverting Valves with Barbed Fittings for Chemicals

Barbed fittings on these valves grip onto tubing, providing a secure hold. To divert flow between ports in chemical-processing applications, they have a chemical-resistant seal and a PVDF body to withstand aggressive and corrosive solutions.

Valves with T-pattern flow can use any port as an inlet or an outlet. Turn the handle to direct flow from the inlet port to either outlet port at full capacity, direct flow to both outlet ports simultaneously at reduced capacity, or shut off flow completely.

- Valve Type: Plug

- For Use With: Air, Butane, Carbon Dioxide, Chlorine, Citric Acid, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Nitric Acid, Nitrogen, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sulfuric Acid, Water

- Seal Material: PVDF Plastic

- Seat Material: PVDF Plastic

Mounting Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| For Tube ID | Port Type | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Mounting Fasteners Included | No. of | Dia. | Each | |

PVDF Plastic Body | |||||||||

Barbed × Barbed × Barbed | |||||||||

| 3/16" to 5/16" | Full | 15 psi @ 65° F | 35° to 100° | 2 1/8" | No | 2 | 5/32" | 0000000 | 000000 |

| 1/4" to 3/8" | Full | 15 psi @ 65° F | 35° to 100° | 2 1/8" | No | 2 | 5/32" | 0000000 | 00000 |

| 3/8" to 1/2" | Full | 15 psi @ 65° F | 35° to 100° | 2 3/4" | No | 2 | 5/32" | 0000000 | 00000 |

| 7/16" to 1/2" | Full | 15 psi @ 65° F | 35° to 100° | 2 3/4" | No | 2 | 5/32" | 0000000 | 00000 |

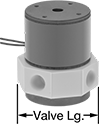

Solenoid Diverting Valves for Chemicals

- For Use With: Acetone, Air, Ammonia, Argon, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Fuel Oil, Helium, Hydrochloric Acid, Krypton, Methanol, Neon, Nitric Acid, Oil, Oxygen, Phosphoric Acid, Salt Water, Sulfuric Acid, Water, Xenon, Xylene

- Seal Material: PTFE Plastic

Often used for chemical analysis and other laboratory testing, these valves have a PTFE seal and body to withstand aggressive and corrosive solutions. All operate on electricity to automatically divert flow between ports. They do not require a pressure drop for operation. Any port can be used as an inlet or an outlet. Valves can direct flow from the inlet port to either outlet port. They cannot shut off flow. The actuator is mounted directly to the valve body to minimize movement and reduce wear.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

Mounting Holes | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Size | Flow Pattern | Flow Coefficient (Cv) | Max. Pressure | Pressure Drop | Min. Pressure Drop Required | Temp. Range, °F | Actuation Time | Valve Lg. | O'all Ht. | Mounting Fasteners Included | No. of | Thread Size | Each | |

PTFE Plastic Body with Wire Leads—12V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 0000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |

PTFE Plastic Body with Wire Leads—24V DC | |||||||||||||||

NPSM Female × NPSM Female × NPSM Female | |||||||||||||||

| 1/8 | __ | L-Pattern | 15.85 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.04 sec. | 1 3/4" | 2" | No | 7 | 4-40 | 0000000 | 000000 |

UNF Female × UNF Female × UNF Female | |||||||||||||||

| __ | 1/4"-28 | L-Pattern | 10.57 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 1 1/2" | 1 13/16" | No | 7 | 4-40 | 0000000 | 000000 |

| __ | 10-32 | L-Pattern | 2.64 | 30 psi @ 70° F | Zero Pressure Drop | None | 35° to 155° | 0.02 sec. | 3/4" | 1 3/16" | No | 5 | 2-56 | 0000000 | 000000 |

Threaded Check Valves for Harsh Chemicals

These valves open to allow flow in one direction and close when flow stops or reverses.

Polypropylene valves are more corrosion resistant than PVC or CPVC valves.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- For Use With: Air, Ammonia, Butane, Carbon Dioxide, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Natural Gas, Nitric Acid, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Sodium Hydroxide, Toluene, Water, Xylene

- Ball Material: 316 Stainless Steel

- Spring Material: 316 Stainless Steel

- Seal Material: Fluoroelastomer Rubber

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

NPT Male × NPT Male | ||||||||

|---|---|---|---|---|---|---|---|---|

| 1/8 | Not Rated | 220 psi @ 70° F | 2.5 | 40° to 180° | White | 1" | 00000000 | 000000 |

| 1/4 | Not Rated | 220 psi @ 70° F | 2.5 | 40° to 180° | White | 1 7/16" | 00000000 | 00000 |

| 3/8 | Not Rated | 220 psi @ 70° F | 2.5 | 40° to 180° | White | 1 1/2" | 00000000 | 00000 |

| 1/2 | Not Rated | 220 psi @ 70° F | 2.5 | 40° to 180° | White | 1 13/16" | 00000000 | 00000 |

Check Valves with Push-to-Connect Fittings for Harsh Chemicals

- For Use With: Air, Argon, Butane, Carbon Dioxide, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Helium, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Krypton, Mineral Spirits, Natural Gas, Neon, Nitric Acid, Nitrogen, Oil, Oxygen, Phosphoric Acid, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Toluene, Water, Xenon, Xylene

- Piston Material: PVDF Plastic

- Spring Material: Stainless Steel

- Seal Material: Fluoroelastomer Rubber

Connect your inlet tubing into the push-to-connect fittings—no heat, solder, or flux required. These valves have a PVDF body and a fluoroelastomer seal for excellent chemical resistance. They open to allow flow in one direction and close when flow stops or reverses.

For technical drawings and 3-D models, click on a part number.

| For Tube OD | Pipe Size | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

PVDF Plastic Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Push-to-Connect Inlet × NPTF Male Outlet | ||||||||

| 3/8" | 1/4 | 300 psi @ 70° F | 0.5 | 0° to 250° | Black | 1 3/8" | 0000000 | 000000 |

Check Valves with Barbed Fittings for Harsh Chemicals

Prevent backflow in chemical tubing lines. These valves have barbed fittings that grip onto tubing, providing a secure hold. The plastic body and fluoroelastomer seal provide excellent chemical resistance. Valves open to allow flow in one direction and close when flow stops or reverses.

PVDF valve resists abrasion and UV light.

- For Use With: Air, Butane, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Gasoline, Hydrochloric Acid, Nitric Acid, Oil, Propane, Salt Water, Soap Solutions, Sodium Hypochlorite, Sulfuric Acid, Water

- Diaphragm Material: Fluoroelastomer Rubber

- Seal Material: Fluoroelastomer Rubber

| For Tube ID | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | Each | |

Barbed × Barbed | |||||||

|---|---|---|---|---|---|---|---|

| 1/4" | 15 psi @ 70° F | 0.5 | -20° to 250° | White | 1 21/32" | 00000000 | 00000 |

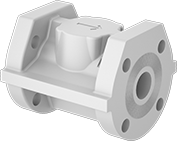

Flanged Check Valves for Harsh Chemicals

- For Use With: Ammonia, Chlorine, Citric Acid, Deionized Water, Diesel Fuel, Ethanol, Ethylene Glycol, Fuel Oil, Gasoline, Hydrochloric Acid, Isopropyl Alcohol, Kerosene, Methanol, Methyl Ethyl Ketone, Mineral Spirits, Oil, Phosphoric Acid, Salt Water, Soap Solutions, Toluene, Water, Xylene

- Ball Material: PTFE Plastic

- Seal Material: PTFE Plastic

Bolt these valves to ANSI flanges. The glass-filled vinyl ester body and PTFE seal stand up to a wide range of harsh chemicals. Valves open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | Color | End-to-End Lg. | For Flange Class | Flange OD | Number of Bolt Holes | Bolt Hole Size | Bolt Circle Dia. | Bolts Included | Each | |

Glass-Filled Vinyl Ester Body | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||||||||

| 1 | 35 | 200 psi @ 250 ° F | 1 | -40° to 250° | Beige | 5" | 150 | 4 1/4" | 4 | 5/8" | 3 1/8" | No | 000000 | 0000000 |

| 2 | 54 | 140 psi @ 250 ° F | 1 | -40° to 250° | Beige | 7" | 150 | 6" | 4 | 3/4" | 4 3/4" | No | 000000 | 000000 |

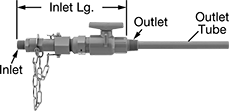

Easy-Maintenance Injectors

A ball valve allows you to isolate the flow to minimize spillage. Outlet tubes can be removed for maintenance and cleaning without shutting down the line. To remove the tube from the pipe, loosen the compression fitting and retract it until the limit chains are taught. Then, close the ball valve and unhook the limit chains. There may be spillage if the process pipe is under pressure.

Outlet | Inlet | Valve | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Tube Lg. | Tube Material | Pipe Size | Thread Type | Gender | Lg. | Lg. | Retractable | Seal Material | Max. Pressure, psi | Material | Type | Each | |

For Chlorine and Water | ||||||||||||||||

| 3/4 | NPT | Male | 6" | CPVC Plastic | 1/2 | NPT | Male | 12 1/4" | 18 1/4" | Retractable | Fluoroelastomer Rubber | 150 | CPVC Plastic | Ball | 0000000 | 0000000 |

| 1 | NPT | Male | 6" | CPVC Plastic | 1/2 | NPT | Male | 15" | 21 1/4" | Retractable | Fluoroelastomer Rubber | 150 | CPVC Plastic | Ball | 0000000 | 000000 |

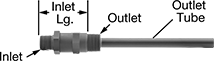

Injectors

Also known as injection quills, use these in applications where the line can be shut down to perform maintenance and cleaning.

Outlet | Inlet | Valve | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Tube Lg. | Tube Material | Pipe Size | Thread Type | Gender | Lg. | Lg. | Retractable | Seal Material | Max. Pressure, psi | Material | Type | Each | |

For Chlorine and Water | ||||||||||||||||

| 1/2 | NPT | Male | 6" | PVC Plastic | 1/2 | NPT | Male | 3 1/4" | 9 1/4" | Nonretractable | Fluoroelastomer Rubber | 150 | PVC Plastic | Check | 0000000 | 0000000 |

| 3/4 | NPT | Male | 6" | PVC Plastic | 1/2 | NPT | Male | 3 1/4" | 9 1/4" | Nonretractable | Fluoroelastomer Rubber | 150 | PVC Plastic | Check | 0000000 | 000000 |