About Backflow-Prevention Valves

More

About Gradual On/Off Valves

More

About Flanged Flow-Adjustment Valves

More

About On/Off Valves

More

Flanged On/Off Valves

Bolt these valves to ANSI flanges. Their lockable lever handle can be fixed in place using a padlock (not included). All have four mounting holes to install an actuator, so you can convert them from manual to automatic valves.

Steel valves stand up to corrosion better than cast iron valves. 316 stainless steel valves are more corrosion resistant than cast iron and steel valves.

Full-port valves do not restrict flow. Standard-port valves slightly restrict flow.

Pressure class 150 valves are standard and work for most low-pressure applications.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

For technical drawings and 3-D models, click on a part number.

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.5, MSS-SP-72

Bolts | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | |||||||||||||

| 8 | 125 | 13 1/2" | 11 3/4" | 8 | 0.88" | No | 4,150 | 200 psi @ 150° F | 125 psi @ 215° F | -20° to 350° | 11 1/2" | 00000000 | 000000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.5

Bolts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | ||||||||||||||

| 8 | 150 | 13 5/8" | 11 3/4" | 8 | 0.88" | No | 9,330 | 275 psi @ 100° F | 100 psi @ 365° F | 0° to 500° | 28 | 18" | 000000000 | 000000000 |

- Valve Type: Ball

- For Use With: Air, Oil, Steam, Water

- Seal Material: PTFE Plastic

- Specifications Met: ANSI/ASME B16.10, ANSI/ASME B16.34, ANSI/ASME B16.5

Bolts | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Circle Dia. | No. of Holes | Hole Size | Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Vacuum Rating, in. of Hg | End-to-End Lg. | Each | |

Flanged × Flanged with Full Port | ||||||||||||||

| 8 | 150 | 13 5/8" | 11 3/4" | 8 | 0.88" | No | 9,330 | 275 psi @ 100° F | 100 psi @ 365° F | 0° to 500° | 28 | 18" | 000000000 | 000000000 |

Flanged × Flanged with Standard Port | ||||||||||||||

| 8 | 150 | 13 1/2" | 11 3/4" | 8 | 0.88" | No | 1,800 | 275 psi @ 100° F | 200 psi @ 365° F | 0° to 450° | 28 | 11 1/2" | 00000000 | 00000000 |

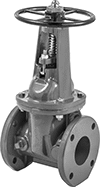

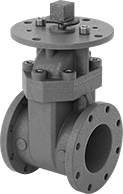

Flanged Gradual On/Off Valves

Nonrising Stem, and

Eight Bolt Holes

Rising Stem, and

Eight Bolt Holes

Easier to install and remove than threaded or weld-on valves, these valves bolt to flanges. They’re often used in lines requiring frequent cleaning and maintenance, such as those for slurries. They open and close gradually, preventing system damage from sudden starts and stops in flow. Also known as gate valves.

Valves with a wheel handle open and close with multiple turns, providing more controlled, shock-resistant flow than valves with a pull handle.

Valves with a nonrising stem keep the handle in the same position whether they’re open or closed. They're often used in low-clearance locations. Valves with a rising stem lift the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. This makes them good for critical lines and lines that need to be opened and closed frequently.

Cast iron valves are stronger than steel valves but more brittle than steel, ductile iron, and stainless steel valves. Steel valves resist impact better than cast iron valves. 316 stainless steel valves have the best corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Water, Oil, Air, Steam

- Specifications Met: ASME B16.10, MSS-SP-70

O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | |||||||||||||||

| 8 | 125 | 13 1/2" | 11 3/4" | 8 | 3/4" | No | Not Rated | 200 psi @ 100° F | 125 psi @ 350° F | -20° to 100° | 11 1/2" | 28 1/2" | 13 3/4" | 000000000 | 000000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Steam

- Specifications Met: ASME B16.10, MSS-SP-70

O'all | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | |||||||||||||||

| 8 | 125 | 13 1/2" | 11 3/4" | 8 | 3/4" | No | Not Rated | 200 psi @ 100° F | 125 psi @ 350° F | -20° to 100° | 11 1/2" | 35 7/8" | 13 3/4" | 00000000 | 000000000 |

- Valve Type: Gate

- For Use With: See table

- Specifications Met: See table

O'all | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | For Use With | Specifications Met | Each | |

Flanged Stem Housing | |||||||||||||||||

| 8 | 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | No | 6,759 | 285 psi @ 100° F | 200 psi @ 350° F | -20° to 800° | 11 1/2" | 35 5/8" | 13 13/16" | Water, Air, Steam | American Petroleum Institute Standard 600, ASME B16.34 | 000000000 | 000000000 |

- Valve Type: Gate

- For Use With: Water, Oil, Air, Steam

- Specifications Met: American Petroleum Institute Standard 603, ASME B16.34

O'all | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Max. Steam Pressure | Temp. Range, °F | Packing Material | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | ||||||||||||||||

| 8 | 150 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 5,250 | 275 psi @ 100° F | 195 psi @ 350° F | -20° to 800° | Graphite | 11 1/2" | 42 5/8" | 13 13/16" | 000000000 | 000000000 |

FM-Approved Flanged Gradual On/Off Valves

FM-approved, these valves are often used to isolate sections of your facility’s water supply for fire suppression and protection. They bolt to flanges for easier installation and removal than threaded or weld-on valves. This makes them a great choice if you have to clean and maintain your line frequently. Also known as gate valves, they open and close gradually to prevent sudden starts and stops of flow that could damage your system. Epoxy coated, these valves resist corrosion. They’re bright red, so they’re easy to identify as fire valves.

Their rubber-coated gate, also known as a resilient wedge, compresses against the valve for a long-lasting, leakproof seal. It seals tightly even if you install these valves vertically, or if there’s low back pressure. For easy disassembly during maintenance, they have a flanged stem housing that bolts in place. However, the housing makes these valves heavier and larger than valves with a threaded or welded stem housing.

Valves with a wheel handle open and close with multiple turns for controlled, shock-resistant flow. Wrench-operated valves are the best choice for hard-to-reach locations, such as underground or inside a manhole. Operate them from a distance with a valve wrench. You can also open and close them with a fire indicator post.

Valves with a nonrising stem keep the handle in the same position whether they’re open or closed. They're often used underground and in low-clearance locations. Valves with a rising stem lift the handle as they open and lower it as they close. At a glance, you can see if flow is on or off. The stem is isolated from what’s flowing through your line, giving these valves a longer lifespan than valves with a nonrising stem. This makes them good for critical lines and lines that need to be opened and closed frequently.

Ductile iron valves are stronger and more durable than cast iron valves. They’ll handle greater pressure changes without cracking.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Gate

- For Use With: Air, Water

- Specifications Met: ASME B16.10, ASTM A126 Class B, AWWA C509, FM Approved, MSS-SP-70, UL Listed

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | |||||||||||||

| 8 | 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 200 psi @ 140° F | 35° to 140° | 11 1/2" | 36" | 11 1/2" | 00000000 | 000000000 |

- Valve Type: Gate

- For Use With: Air, Water

- Specifications Met: AWWA C515, FM Approved, UL Listed

O'all | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Each | |

Flanged Stem Housing | |||||||||||||

| 8 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 757 | 300 psi @ 100° F | 35° to 170° | 11 1/2" | 45 3/16" | 15 3/4" | 0000000 | 000000000 |

- Valve Type: Gate

- For Use With: Drinking Water, Water

- Specifications Met: FM Approved, NSF/ANSI 61, UL Listed

O'all | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Dia. | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Ht. | Lg. | Drive Style | Drive Size | Features | Each | |

Flanged Stem Housing | |||||||||||||||||

| 8 | 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 4,150 | 300 psi @ 100° F | 35° to 140° | 11 1/2" | 27 1/2" | 11 1/2" | External Square | 2" | Indicator Post Mounting Flange | 0000000 | 000000000 |

Flanged Flow-Adjustment Valves

Also known as butterfly valves, these bolt to flanges for adjusting and regulating flow in flanged pipelines.

Wafer valves must be sandwiched between two flanges; they have tabs or unthreaded holes to help align the valve between the flanges.

Lug valves can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Wheel handles open and close with multiple turns, providing fully adjustable flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc: Air

Ductile Iron Disc: Water - Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

Ductile Iron Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 4 | 3/4" | No | 3,136 | 200 psi @ 180° F | 10° to 180° | 2 1/2" | 00000000 | 000000000 |

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 4 | 3/4" | No | 3,136 | 200 psi @ 275° F | -30° to 275° | 2 1/2" | 00000000 | 00000000 |

Ductile Iron Body—Ductile Iron Disc | ||||||||||||

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | No | Not Rated | 250 psi @ 180° F | -20° to 180° | 2 1/2" | 0000000 | 000000 |

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | No | Not Rated | 250 psi @ 225° F | -20° to 225° | 2 1/2" | 00000000 | 000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc: Air

Ductile Iron Disc: Water - Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

Ductile Iron Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | For Bolt Diameter | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | 3/4" | No | 3,136 | 200 psi @ 180° F | 10° to 180° | 2 1/2" | 00000000 | 000000000 |

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | 3/4" | No | 3,136 | 200 psi @ 275° F | -30° to 275° | 2 1/2" | 00000000 | 00000000 |

Ductile Iron Body—Ductile Iron Disc | |||||||||||||

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | 3/4" | No | Not Rated | 250 psi @ 180° F | -20° to 180° | 2 1/2" | 0000000 | 000000 |

| 8 | 125, 150 | 13 1/2" | 11 3/4" | 8 | 3/4" | 3/4" | No | Not Rated | 250 psi @ 225° F | -20° to 225° | 2 1/2" | 00000000 | 000000 |

Flanged Flow-Adjustment Valves for Chemicals

With seats that can stand up to aggressive and corrosive solutions, these valves are often used in chemical-processing applications. They bolt to flanges for adjusting and regulating flow in flanged pipelines.

Wafer valves must be sandwiched between two flanges; they have tabs or unthreaded holes to help align the valve between the flanges.

Lug valves can be sandwiched between two flanges or bolted directly to a single flange for servicing one end of the pipeline without depressurizing the other side. They have threaded flange holes with a hole pattern that matches ANSI flanges of the same pipe size.

Wheel handles open and close with multiple turns, providing fully adjustable flow.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 4 | 7/8" | No | 3,136 | 200 psi @ 275° F | 10° to 275° | 2 1/2" | 000000000 | 000000000 |

Ductile Iron Body—316 Stainless Steel Disc | ||||||||||||

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 1/2" | 0000000 | 00000000 |

- Valve Type: Butterfly

- For Use With:

Painted Ductile Iron Disc:

Air, Carbon Dioxide, Diesel Fuel, Isopropyl Alcohol, Methyl Ethyl Ketone, Nitrogen, Oxygen, Toluene

316 Stainless Steel Disc:

Carbon Dioxide, Gasoline, Liquid Carbon Dioxide, Phosphoric Acid - Seat Material: Fluoroelastomer Rubber

- Specifications Met:

Painted Ductile Iron Disc: MSS-SP-67

316 Stainless Steel Disc: API 609, MSS-SP-67

| Pipe Size | Pressure Class | Flange OD | Bolt Circle Dia. | No. of Bolt Holes | Bolt Hole Size | Bolts Included | Flow Coefficient (Cv) | Max. Pressure | Temp. Range, °F | End-to-End Lg. | Each | |

Ductile Iron Body—Painted Ductile Iron Disc | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | 3,136 | 200 psi @ 275° F | 10° to 275° | 2 1/2" | 000000000 | 000000000 |

Ductile Iron Body—316 Stainless Steel Disc | ||||||||||||

| 8 | 150, 125 | 13 1/2" | 11 3/4" | 8 | 7/8" | No | Not Rated | 250 psi @ 210° F | -20° to 210° | 2 1/2" | 000000 | 00000000 |

Flange-Mount Check Valves

- For Use With: Air, Argon, Helium, Krypton, Neon, Water, Xenon

- Disc Material: Bronze

- Seal Material: Buna-N Rubber

Sandwich these valves between two ANSI flanges for backflow prevention at a fraction of the weight of flanged check valves and a reduced pipeline footprint. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

Cast Iron Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 8 | 1,600 | 200 psi @ 70° F | 1.25 | -20° to 250° | 3 3/4" | 125 | 0000000 | 0000000 |

Flanged Check Valves

- For Use With: Air, Steam, Water

- Disc Material:

Pipe Size 4 and smaller: Bronze

Pipe Size 5 and larger: Iron - Seal Material: Bronze

Bolt these valves to ANSI flanges. They open to allow flow in one direction and close when flow stops or reverses. All have a removable cap that provides easy access to internal components for maintenance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Pressure Class | Max. Pressure | Max. Steam Pressure | Min. Opening Pressure | Temperature Range, °F | End-to-End Lg. | Flange OD | No. of Bolt Holes | Bolt Hole Size | Bolt Circle Dia. | Bolts Included | Includes | Each | |

Cast Iron Body | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | |||||||||||||||

| 8 | 1,880 | 125 | 200 psi @ 70° F | 125 psi @ 353° F | 1 psi | -20° to 405° | 19 1/2" | 13 1/2" | 8 | 3/4" | 11 3/4" | No | Removable Cap | 0000000 | 000000000 |

Flange-Mount Check Valves for Oil and Fuel

- For Use With: Butane, Diesel Fuel, Fuel Oil, Gasoline, Kerosene, Natural Gas, Oil, Propane

- Disc Material: 316 Stainless Steel

- Seal Material: 316 Stainless Steel

Install these valves between ANSI flanges. ANSI flanges are sold separately. All valves open to allow flow in one direction and close when flow stops or reverses. Body is 316 stainless steel for excellent corrosion resistance.

Flow coefficient (Cv) is the amount of water (in gallons per minute) at 60° F that will flow through a fully open valve with a difference of 1 psi between the inlet and the outlet.

| Pipe Size | Flow Coefficient (Cv) | Max. Pressure | Min. Opening Pressure, psi | Temperature Range, °F | End-to-End Lg. | For Flange Class | Each | |

316 Stainless Steel Body | ||||||||

|---|---|---|---|---|---|---|---|---|

Flanged × Flanged | ||||||||

| 8 | 1,795 | 275 psi @ 70° F | 1.25 | -20° to 1000° | 5" | 150, 300 | 0000000 | 000000000 |