Filter by

Overall Length

For Use With

Overall Width

Length

Width

Specifications Met

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Message

Performance

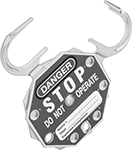

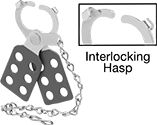

Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 2 1/16" | Red | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 12 | 3/8" | 6 1/2" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 24 | 1/4" | 10 3/8" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 4 1/2" | 1 3/4" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5" | 2 3/8" | Red | OSHA Compliant 29 CFR 1910.147 | 000000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Epoxy Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 3/8" | 6 | 3/8" | 5 1/16" | 1 3/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 5 1/16" | 2 1/4" | Yellow | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl Coated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 7/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1 1/4" | 1/4" | 6 | 5/16" | 4 9/16" | 1 1/2" | Red | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Choose-a-Color Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Choose a Color | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/16" | 1 3/8" | 3/16" | 6 | 5/16" | 7 3/8" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | Blue , Green , Red | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

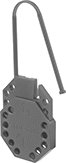

Nonconductive Lockout Hasps

|  |  |  | |

Style A | Style B | Style C | Style D | Style E |

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1" | 1" | 3/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/2" | 1 1/2" | 3/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 3/4" | 3/4" | 1" | 2 | 1 1/2" | 4 3/4" | 2 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | 1 15/16" | 1" | 1/4" | 3 | 1/4" | 8" | 1 3/4" | Red | Yes | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| D | 3 1/2" | 1 1/4" | 3/8" | 6 | 3/8" | 7" | 1 3/4" | Orange | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| E | 3 1/2" | 1 1/4" | 1/2" | 12 | 1/4" | 7 1/4" | 3 1/4" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

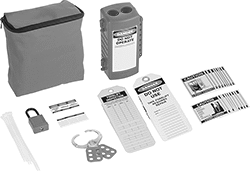

Lockout Bags

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Canvas | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 9/32" | 18" | 9 3/4" | Yellow | Yes | English | Lock Out For Safety | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 17" | 7" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 9/32" | 26" | 10" | Red | Yes | English, Spanish, French | Locked Out—Do Not Remove Cerrado—No Lo Quite Verrouille—Ne Pas Enlever | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyester Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 5/16" | 5" | 5" | Red | Yes | English | Locked Out—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.145, OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Chain Sets with Padlocks

For Use With | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Electrical Panels, Pipe Flanges, Valves | 2 Each: Lockout Hasps 5 Each: Cable Ties 5 Each: Tags 1 Each: 4 ft. Chain Lockout 2 Each: 1/4" Shackle Diameter Keyed Differently Padlocks Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Pry-Resistant Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/8" | 1" | 1/8" | 2 | 9/32" | 3 1/8" | 2 3/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 6 | 3/8" | 6 3/4" | 2 1/4" | — | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/4" | 1" | 1/4" | 6 | 3/8" | 5" | 2 5/16" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 6 | 7/16" | 4 3/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/4" | 6 | 7/16" | 4 7/8" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Interlocking-Hasp Lockouts

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/2" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/2" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | Red | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Forklift Lockout Sets with Padlock

For Use With | Includes | Specs. Met | Each | ||

|---|---|---|---|---|---|

| Battery Cable Connectors, Electrical Plugs, Gas Cylinders | 10 Each: Cable Ties 1 Each: Plug Lockout 1 Each: 1/4" Shackle Diameter Keyed Differently Padlock with Label 1 Each: Lockout Hasp 10 Each: Forklift Inspection Tags 10 Each: Lockout Tags 20 Each: Safety Labels Carrying Case | OSHA Compliant 29 CFR 1910.147 | 0000000 | 0000000 |

Pendant Switch Lockouts

For Switch | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Max. Wd. | Lg. | Wd. | Dp. | Temp. Range, ° F | Color | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic/Fabric | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3/8" | 4" to 18" | 5" | 11" to 20" | 5 1/4" | 5 1/4" | -40 to 212 | Red | No | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Lockout Hasps with Padlock Slot

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Body Ht. | Lg. | Wd. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/4" | 5 | 5/16" | 2" | 3 1/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 3/8" | 6 | 7/16" | 3 1/2" | 5 3/8" | 2 1/2" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/8" | 9 | 5/16" | 3 1/2" | 6 5/8" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1" | 1/4" | 9 | 5/16" | 3 1/2" | 6 3/4" | 2 1/4" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | 1 1/2" | 1/4" | 3 | 3/8" | 2" | 7" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Profile Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nickel-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1 1/4" | 1/4" | 7 | 3/8" | 3" | 3" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasps with Label

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Label Included | Language | Message | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 1 1/8" | 2 1/16" | 3/16" | 6 | 5/16" | 5 7/16" | 3 7/16" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Anodized Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 1 1/2" | 1 1/2" | 3/16" | 6 | 9/32" | 7" | 2 3/4" | Red | Yes | English | Danger—Do Not Operate | OSHA Compliant 29 CFR 1910.147 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

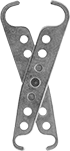

Dual-Jaw Lockout Hasps

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thickness | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Label Included | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2" x 1" | 1/2" x 1" | 5/16" x 5/16" | 6 | 5/16" | 7 3/4" | 1 3/8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" x 1 1/2" | 1" x 1 1/2" | 1/4" x 1/4" | 8 | 9/32" | 5 7/8" | 2" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas Cylinder Lockouts

Plastic

Style | For Hand Wheel Dia. Range | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Overall Lg. | Max. Temp., ° F | Color | Message | Specs. Met | Each | |||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | 1 1/4" to 2 3/16" | 3 | 5/16" | 3 1/2" | 200 | Yellow | Danger—Do Not Operate—Equipment Locked Out | OSHA Compliant 29 CFR 1910.147, UL ECVP 2809-2 | 00000000 | 000000 | ||

Powder-Coated Steel

Thread | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Type | Spacing | Direction | Gender | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Overall Lg. | Max. Temp., ° F | Color | Includes | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Low Pressure Gas Cylinders | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | UNC | Coarse | Right Hand | Female | 1 | 1/4" | 11" | 200 | Yellow | Padlock Three Keys | OSHA Compliant 29 CFR 1910.147 | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | UNF | Fine | Right Hand | Female | 1 | 1/4" | 11" | 200 | Yellow | Padlock Three Keys | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For High Pressure Gas Cylinders | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | UNC | Coarse | Right Hand | Female | 1 | 1/4" | 11" | 200 | Yellow | Padlock Three Keys | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| C | UNF | Fine | Right Hand | Female | 1 | 1/4" | 11" | 200 | Yellow | Padlock Three Keys | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nonconductive Lockout Hasps with Tag Holder

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Color | Tag Included | Features | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 3/4" | 1 3/8" | 1/2" | 3 | 5/16" | 5 1/4" | 3" | Red | No | Tag Holder | OSHA Compliant 29 CFR 1910.147 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

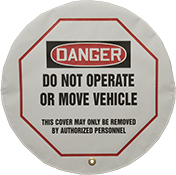

Lockout Steering Wheel Covers

For Max. Steering Wheel Dia. | Dia. | Thk. | Material | Grommet Material | Hole Dia. | Specs. Met | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Danger—Do Not Operate or Move Vehicle (English) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 16 1/2" | 1/4" | Vinyl Plastic | Metal | 3/8" | OSHA Compliant 29 CFR 1910.145 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 20 1/2" | 1/4" | Vinyl Plastic | Metal | 3/8" | OSHA Compliant 29 CFR 1910.145 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Caution—This Vehicle is Being Serviced Do Not Attempt to Drive (English) | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 16" | 16 1/2" | 1/4" | Vinyl Plastic | Metal | 3/8" | OSHA Compliant 29 CFR 1910.145 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20" | 20 1/2" | 1/4" | Vinyl Plastic | Metal | 3/8" | OSHA Compliant 29 CFR 1910.145 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pry-Resistant Interlocking-Hasp Lockouts with Chain

Hasp Clearance | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Vertical | Horizontal | Hasp Thk. | For Max. No. of Padlocks | For Max. Padlock Shackle Dia. | Lg. | Wd. | Mounting Chain Lg. | Label Included | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lockout Hasp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vinyl-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1" | 1" | 1/8" | 6 | 3/8" | 4 1/2" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1 1/2" | 1/8" | 6 | 3/8" | 5" | 1 1/2" | 8" | No | OSHA Compliant 29 CFR 1910.147 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||