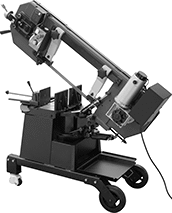

Adjustable Band Saws for Metal

Highly versatile, these saws make precise horizontal and vertical cuts from a single saw. They work well whether you’re simply cutting metal into smaller pieces or creating complex shapes. When the blade is horizontal, these saws cut from above, making square or angled cuts. For straight or intricate curved cuts, position the blade vertically and feed your workpiece through. They’re powerful enough to cut through aluminum, steel, and stainless steel. However, they should only be used for dry cutting.

The higher the horsepower, the smoother the cut, even in thick and hard metals.

Direct-drive saws send power straight to the blade instead of a belt, which keeps power and speed steady when cutting thick, hard metals. They also have fewer parts, which means they need less maintenance.

Saws with an automatic feed push material into the blade at a steady pace, so they’re more accurate than those you feed manually. Once the blade reaches your material, the weight of the saw head completes the cut for you.

Max. Cutting | Blade | Overall | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Current | Power, hp | Drive Type | Dia. | Dp. | Ht. | Max. Miter Cut Angle (Swivel Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Wt., lbs. | No. of Wheels | Each | |

Manual Feed System | |||||||||||||||||

| 5 A @ 120 V AC | 1 1/4 | Direct | 10" | 8" | 10" | 45° (Left/Right) | 65-250 | 118" | 1" | 0.035" | 60" | 24" | 50" | 560 | 4 | 00000000 | 000000000 |

| 8 A @ 120 V AC 4 A @ 240 V AC | 1/2 | Belt | 5" | 5" | 5 3/4" | 45° (Left) | 80, 120, 200 | 64 1/2" | 1/2" | 0.025" | 36" | 20" | 39 1/2" | 115 | 2 | 0000000 | 000000 |

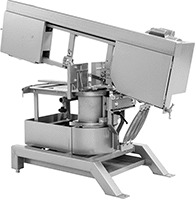

Automatic Feed System | |||||||||||||||||

| 20 A @ 120 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

| 20 A @ 120 V AC 20 A @ 240 V AC | 1 | Belt | 10" | 7" | 9" | 45° (Left/Right) | 70, 135, 250 | 120" | 1" | 0.037" | 59 1/4" | 24 3/4" | 47" | 475 | 2 | 0000000 | 00000000 |

| 20 A @ 120 V AC 20 A @ 240 V AC | 1 | Belt | 11" | 11" | 10" | 45° (Left/Right) | 70, 135, 250 | 132" | 1" | 0.037" | 66" | 29" | 47" | 650 | 0 | 0000000 | 00000000 |

| 20 A @ 240 V AC | 1 1/2 | Belt | 11" | 13" | 11" | 60° (Left/Right) | 60, 115, 230 | 144" | 1" | 0.037" | 72" | 38 1/4" | 47" | 680 | 0 | 00000000 | 00000000 |

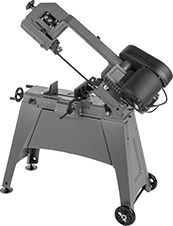

Bench-Top Band Saws for Metal

Save space with these saws when you only need to make cuts in small pieces of metal. For smoother cuts in thick and hard metals, choose a saw with higher horsepower (hp). Saws with higher horsepower also handle continuous use better. These band saws are only for dry cutting.

Vertical-blade saws—roughly the size of a mini-fridge—are for curved, detailed, and intricate cuts. If you use a fence as a guide, these saws can also make straight cuts in long pieces of material. Connect the chip collection port to a dust collector to keep your work area clean. These saws are compatible with replacement blades between 67”-68” long.

Max. Cutting | Blade | Overall | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Power, hp | Current | Dia. | Dp. | Ht. | Work Table Tilt Angle (Tilt Direction) | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Lg. | Wd. | Ht. | Features | Each | |

Manual Feed System | |||||||||||||||

| 1/3 | 3.5 A @ 120 V AC | 4" | 9 1/2" | 4" | 45° (Right) | 250, 350, 450 | 67 3/8" | 1/2" | 0.025" | 21" | 16 1/2" | 34" | Chip Collection Port | 00000000 | 0000000 |

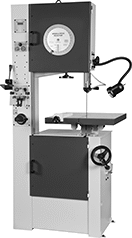

Vertical Band Saws

Make precise cuts in a variety of materials by pushing your workpiece through the vertical blade. Unlike horizontal band saws, these saws can make curved and intricate cuts. They can also make straight cuts when you use a fence to guide your material.

Style A saws are a good choice if you’re only cutting wood and plastic.

Style B saws are more versatile than Style A saws because they cut through metal in addition to wood and plastic. They have a chip collection system that blows debris away from your cut line and into a chip chute. Hook up your dust collector to the chip collection port to suck away the debris.

Style C saws can cut through the thickest and hardest material without stalling because they produce the most torque compared to these other styles. Designed to run at lower speeds, they can cut through plastics and metals, including steel and other hard metals. To help you see your cut line, they have a chip blower that keeps debris out of the way and a light for illuminating your work. These saws come with a blade maintenance station, so you can create band saw blades from coil stock, repair broken blades, and sharpen your blades.

Max. Cutting | Blade | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Style | Current | Power, hp | Dia. | Dp. | Ht. | No-Load Speed, sfpm | Lg. | Wd. | Thick. | Features | Includes | Each | |

| A | 9.5 A @ 120 V AC | 1 | 13" | 13 1/2" | 13" | 1,445; 3,150 | 101" | 3/4" | 0.025" | Material Guide Fence Floor Stand Dust Collection Port Miter Gauge | One 101" Lg. × 3/4" Wd. Carbon Steel Blade for Wood and Plastic (4 Teeth per Inch) | 00000000 | 0000000 |

| B | 14 A @ 120 V AC 7 A @ 240 V AC | 1 | 10" | 15" | 10" | 45; 65; 90; 110; 155; 215; 3,000 | 114" | 1/2" | 0.035" | Material Guide Fence Chip Blower Chip Chute Chip Collection Port Miter Gauge | One 114" Lg. × 1/2" Wd. Carbon Steel Blade for Wood (6 Teeth per Inch), One 114" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 0000000 | 00000000 |

| B | 20 A @ 120 V AC 10 A @ 240 V AC | 1 1/2 | 12" | 18" | 12" | 45; 65; 90; 110; 155; 215; 3,000 | 136" | 3/4" | 0.035" | Material Guide Fence Chip Blower Chip Chute Chip Collection Port Miter Gauge | One 136" Lg. × 3/4" Wd. Carbon Steel Blade for Wood (8 Teeth per Inch), One 136" Lg. × 3/4" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 00000000 | 00000000 |

| C | 18 A @ 120 V AC 9 A @ 240 V AC | 1 1/2 | 11" | 18" | 11" | 82-385 | 140" | 1/2" | 0.025" | Chip Blower Blade Maintenance Station Work Light Carbide Blade Guides | One 140" Lg. × 1/2" Wd. Carbon Steel Blade with High-Speed Steel Teeth for Metal (14 Teeth per Inch) | 00000000 | 00000000 |

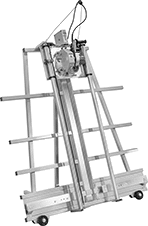

Panel Saws

A circular saw mounted to a track allows you to make straight vertical and horizontal cuts in large sheets of wood and plastic that won't fit on a table saw.

Quick stops are adjustable for repetitive horizontal cuts of any length up to 96".

Extensions add 20" to each side of the saw frame for extra support when cutting wide panels.

Dust hose exhaust kit includes a 20 ft. long, 1 1/2" dia. hose and everything you need to connect it to your saw.

Saws | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall | Quick Stops | |||||||||||||

| Max. Vertical Cut | Max. Horizontal Cut | Current | For Blade Dia. | For Arbor Hole Size | No-Load Speed, rpm | Max. Cutting Dp. | Ht. | Wd. | Wt., lbs. | Blade Included | Each | Each | ||

| 50" | 96" | 15 A @ 120 V AC | 8" | 5/8" | 5,800 | 1 3/4" | 75" | 60" | 190 | Yes | 00000000 | 000000000 | 00000000 | 0000000 |

| 64" | Any | 15 A @ 120 V AC | 8" | 5/8" | 5,800 | 1 3/4" | 90" | 120" | 298 | No | 00000000 | 00000000 | 00000000 | 000000 |

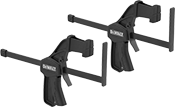

Electric Track Saws

Take these saws anywhere and use the included track to make perfectly straight, splinter-free cuts in wood. They are also called plunge saws because they can make plunge cuts. Control the speed of the blade with a dial; use slower speeds for hard wood and faster speeds for soft wood. A second dial lets you have precise control over the depth of the cut. These saws also have a riving knife that reduces kickback by keeping the cut material from pinching the blade. Connect a vacuum hose to the dust port to collect up to 90% of the sawdust created so you can keep your work area clean. Optional track clamps hold the track to your workpiece.

| Manufacturer | Manufacturer Model No. | Current | For Arbor Hole Size | For Blade Dia. | No-Load Speed, rpm | Max. Cutting Depth | Wt., lbs. | Includes | Features | Each | |

| DeWalt | DWS520CK | 12 A @ 120 V AC | 20 mm | 6 1/2" | 1,750-4,000 | 2 1/8" | 11.5 | One 6 1/2" Dia. Carbide-Tipped Steel Blade for Wood (48 Teeth); 59" Lg. Track; 102" Lg. Track | Speed Control, Depth Control, Kickback Reduction, Dust Extraction Port | 000000 | 0000000 |

| Manufacturer | No. of Clamps | Each | |

| DeWalt | 2 | 0000000 | 000000 |

Track Saw Blades for Wood

Make perfectly straight cuts in wood, plywood, and particleboard with minimal splintering. These blades fit in your track saw to cut along the precision track. They make straight and plunge cuts, so they’re good for cutting a sheet of wood into precise pieces before fabrication or construction.

When choosing a blade, you’ll want to keep in mind the number of teeth and width of cut. Choose more teeth for cutting across the grain or when you want a smoother cut; choose fewer teeth for cutting with the grain (ripping) or when you want a faster cut. Blades with fewer teeth also cut thicker materials. A narrower cut width makes faster cuts with minimal material loss; a wider cut width increases stability for straighter cuts.

Blades with anti-vibration vents add stability for even straighter, more accurate cuts. They have a coating that resists heat buildup when cutting, which helps keep them sharp. They stay cool as you cut, so sawdust won’t stick to them as easily, and they won’t burn your wood.

Warning: Use blades that have a greater rpm rating than the no-load rpm of your saw.

Material | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Arbor Hole Size, mm | Arbor Hole Shape | Number of Teeth | Width of Cut | Maximum Speed, rpm | Tooth | Body | Cut Type | Features | Each | |

6 1/2" Dia. | ||||||||||

| 20 | Round | 24 | 0.063" | 10,000 | Carbide | Steel | Across Grain, With Grain (Rip Cut) | Anti-Vibration Vents | 0000000 | 000000 |

| 20 | Round | 40 | 0.063" | 10,000 | Carbide | Steel | Across Grain, With Grain (Rip Cut) | Anti-Vibration Vents | 0000000 | 00000 |

| 20 | Round | 48 | 0.086" | 7,000 | Carbide | Steel | Across Grain, With Grain (Rip Cut) | __ | 0000000 | 00000 |

High-Force Sheet Metal Cutters with Offset Handles for Tight Spaces

- Straight,

Right Curves

- Straight,

Left Curves

The handles are angled 90° from the blade so you can cut material from directly above in tight spaces. Also known as aviation snips, these cutters have a double hinge that provides high cutting force with low gripping pressure. A spring opens the jaws for quick cutting, and a locking latch holds them together when the cutter is not in use. Blades are serrated to prevent slipping.

For Max. Thick. | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Overall Lg. | Cut Lg. | Steel | Stainless Steel | Blade Material | Handle Material | Handle Color | Grip Material | Opening Style | Blade Edge | Lock Type | Each | |

Cutting Pattern—Straight, Right Curves | ||||||||||||

For Use On Aluminum, Brass, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel, Tin | ||||||||||||

| 8 3/4" | 1 1/4" | 1/64" | 1/64" | Steel | Steel | Green | Plastic | Spring Assisted | Serrated × Serrated | Latch | 0000000 | 000000 |

Cutting Pattern—Straight, Left Curves | ||||||||||||

For Use On Aluminum, Brass, Copper, Iron, Nickel, Plastic, Stainless Steel, Steel, Tin | ||||||||||||

| 8 3/4" | 1 1/4" | 1/64" | 1/64" | Steel | Steel | Red | Plastic | Spring Assisted | Serrated × Serrated | Latch | 0000000 | 00000 |

Paper Roll Cutters

Cleanly tear off paper to the length you need.

Cutters for two, three, or four rolls are great if you’re packing items with different types of paper. For example, you could use them to cut general purpose paper for plastic parts and wax-coated paper for lubricated metal parts.

For Max. Roll | Mounting Holes | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Number of Rolls | Wd. | OD | Lg. | Wd. | Ht. | Material | Mounting Location | Mounting Fasteners Included | No. of | Dia. | Features | Assembled or Unassembled | Each | |

Vertical | ||||||||||||||

| 1 | 27" | 9" | 14" | 14" | 35" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 00000000 | 0000000 |

| 1 | 36" | 9" | 14" | 14" | 44" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 0000000 | 000000 |

| 1 | 48" | 9" | 14" | 14" | 56" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 0000000 | 000000 |

| 1 | 60" | 20" | 20" | 26" | 69" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Gravity Blade | Unassembled | 00000000 | 000000 |

| 2 | 27" | 9" | 26" | 25" | 35" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 00000000 | 000000 |

| 2 | 36" | 9" | 26" | 25" | 44" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 00000000 | 000000 |

| 2 | 48" | 9" | 26" | 25" | 56" | Powder-Coated Steel | Floor | No | 4 | 1/2" | Spring-Loaded Blade | Unassembled | 00000000 | 000000 |

Wheel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Dia. | Wd. | Mount Ht. | Cap. per Caster, lbs. | Stem Thread Size | Stem Lg. | Caster Type | Wheel/Tread Material | Pkg. Qty. | Pkg. | |

| 3" | 1 1/4" | 3 1/2" | 125 | 1/2"-13 | 1 1/2" | 2 Swivel and 2 Swivel with Brake | Polypropylene Plastic | 4 | 0000000 | 000000 |