Filter by

Vise Type

System of Measurement

Jaw Style

Mounting Hole Center-to-Center

Body Length

Jaw Material

Overall Height

For Machine Type

Height

DFARS Specialty Metals

Jaw Mounting Hole Center-to-Center

Export Control Classification Number (ECCN)

RoHS

Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 1" | 1 1/2" | Steel | Smooth, Grooved | Yes | 2" | 4 1/4" | Iron | Bolt On | No | 2 | 3/8" | 2 5/8" | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/8" | 3" | Steel | Smooth, Grooved | Yes | 2 1/2" | 6 5/8" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 6 3/4" | Iron | Bolt On | No | 2 | 9/16" | 3 9/16" | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 2 7/8" | 7 5/8" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 5/8" | 11" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8" | Steel | Smooth, Grooved | Yes | 3 5/8" | 15 1/2" | Iron | Bolt On | No | — | — | — | Open Base | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

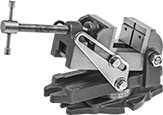

Any-Orientation Drill-Press Vises

With Flat Jaws

Jaw | Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 1" | 1 1/2" | Steel | Smooth, Grooved | Yes | 1 7/8" | 5 1/8" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/16" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 7 1/2" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 3/4" | 3" | Steel | Smooth | Yes | 3" | 9" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 3 1/4" | 10 3/4" | Iron | Clamp On | Open Base | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 1/2" | 11 3/8" | Iron | Clamp On | Open Base | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Clamp Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Lever Jaw Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/4" | 3" | Steel | Smooth | Yes | 2 3/4" | 9" | Iron | Bolt On | No | 4 | 1/2" | Open Base Stepped Jaws | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 5/16" | 4 5/8" | Steel | Smooth | Yes | 3 1/4" | 11 3/4" | Iron | Bolt On | No | 4 | 17/32" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 13/16" | 6 1/8" | Steel | Smooth | Yes | 3 3/4" | 14 3/4" | Iron | Bolt On | No | 4 | 11/16" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8 1/8" | Steel | Smooth | Yes | 4 1/2" | 17 7/8" | Iron | Bolt On | No | 4 | 11/16" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Pump-Action-Lever Jaw Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/4" | 3" | Steel | Smooth | Yes | 2 3/4" | 9" | Iron | Bolt On | No | 4 | 1/2" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 5/16" | 4 5/8" | Steel | Smooth | Yes | 3 1/4" | 11 3/4" | Iron | Bolt On | No | 4 | 17/32" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 13/16" | 6 1/8" | Steel | Smooth | Yes | 3 3/4" | 14 3/4" | Iron | Bolt On | No | 4 | 11/16" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8 1/8" | Steel | Smooth | Yes | 4 1/2" | 17 7/8" | Iron | Bolt On | No | 4 | 11/16" | Open Base Stepped Jaws | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Screw Jaw Lock | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/2" | 3" | Steel | Smooth, Grooved | Yes | 2 5/8" | 9" | Steel | Bolt On | No | 4 | 1/2" | Stepped Jaws | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/2" | 6" | Steel | Smooth, Grooved | Yes | 3" | 13" | Steel | Bolt On | No | 4 | 1/2" | Stepped Jaws | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 8" | Steel | Smooth, Grooved | Yes | 3 7/8" | 17" | Steel | Bolt On | No | 8 | 5/8" | Stepped Jaws | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 3" | 10" | Steel | Smooth, Grooved | Yes | 5 1/2" | 21 3/4" | Steel | Bolt On | No | 8 | 7/8" | Stepped Jaws | 0000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

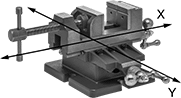

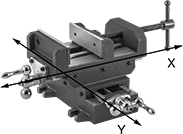

High-Precision Cross-Slide Drill-Press Vises

With Flat Jaws

Jaw | Max. Travel | Base | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Parallel Tolerance | X-Axis | Y-Axis | Adjustment Dial Graduations | Overall Ht. | Lg. | Wd. | Body Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 3/4" | 3" | Steel | Smooth, Grooved | Yes | 0.001" | 4" | 4" | 0.001" | 5 1/2" | 7 1/2" | 6 1/4" | Iron | Bolt On | No | 4 | 5/8" | 00000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Cross-Slide Drill-Press Vises

With Flat Jaws

Jaw | Max. Travel | Base | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | X-Axis | Y-Axis | Adjustment Dial Graduations | Overall Ht. | Lg. | Wd. | Body Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 3/8" | 3" | Steel | Smooth, Grooved | Yes | 5" | 5" | 0.002" | 5 7/8" | 8 3/8" | 4 5/8" | Iron | Bolt On | No | 5 | 1/2" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 8" | 8" | 0.001" | 7 3/8" | 12 1/8" | 7 1/8" | Iron | Bolt On | No | 5 | 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 2" | 8" | Steel | Smooth, Grooved | Yes | 8" | 8" | 0.001" | 7 3/8" | 12 1/8" | 7 1/8" | Iron | Bolt On | No | 5 | 5/8" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

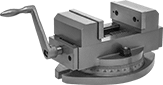

Self-Centering Machine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Base Graduations | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/2" | 4" | Steel | Smooth | Yes | 6 3/32" | 11 13/32" | Steel | 0.0012" | 1° | Bolt On | No | 2 | 1/2" | 8" | Self-Centering Jaws | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ultra-Precision Machine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Parallel Tolerance | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 3 1/4" | Steel | Smooth, Grooved | Yes | 0.0002" | 2" | 5 7/8" | Steel | 0.0002" | Bolt On | No | 4 | 5/16" | 1" | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 5/16" | 4 3/4" | Steel | Smooth, Grooved | No | 0.0002" | 2 5/8" | 7 1/2" | Steel | 0.0002" | Bolt On, Clamp On | No | 4 | 5/16" | — | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Base Graduations | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 3 3/8" | 8 3/4" | Iron | 0.001" | — | Bolt On | No | 2 | 9/16" | 4 5/8" | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth, Grooved | Yes | 3 7/8" | 11 1/2" | Iron | 0.001" | — | Bolt On | No | 2 | 5/8" | 6 1/2" | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/2" | 4" | Steel | Smooth | Yes | 4 9/16" | 14 7/16" | Iron | 0.002" | 1° | Bolt On | No | 2 | 1/2" | 4 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2" | 6" | Steel | Smooth | Yes | 6 3/16" | 20 3/16" | Iron | 0.002" | 1° | Bolt On | No | 2 | 5/8" | 6 7/16" | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

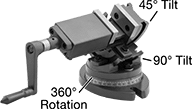

Any-Angle Machine Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base Graduations | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2" | 1" | 2" | Steel | Smooth | Yes | 5 19/32" | 9" | Iron | 1° | Bolt On | No | 2 | 1/2" | 4 3/4" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/2" | 4" | Steel | Smooth | Yes | 10 13/32" | 19 45/64" | Iron | 1° | Bolt On | No | 2 | 5/8" | 8 1/4" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 3/4" | 6" | Steel | Smooth | Yes | 13 19/64" | 19" | Iron | 1° | Bolt On | No | 2 | 5/8" | 10 3/4" | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

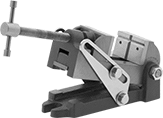

Pivoting-Head Drill-Press Vises

With Flat Jaws

Jaw | Body | Mounting Holes | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Overall Ht. | Lg. | Material | Base Graduations | Mount Type | Mounting Fasteners Included | No. of | Dia. | Ctr.-to-Ctr. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 1 1/2" | 2 1/2" | Steel | Smooth, Grooved | Yes | 3 7/8" | 9" | Iron | — | Bolt On | No | 2 | 1/2" | 6 11/16" | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

360° Swivel Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 7/8" | 1 1/2" | 2 1/2" | Steel | Smooth, Grooved | Yes | 4 5/8" | 8" | Iron | 5° | Bolt On | No | 4 | 1/2" | 6 13/16" | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 3/4" | 4" | Steel | Smooth, Grooved | Yes | 6 1/4" | 12" | Iron | 1° | Bolt On | No | 2 | 1/2" | 7 7/8" | 000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Air-Powered Machine Vises

With Flat Jaws

Jaw | Air Inlet | Body | Mounting Holes | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Pipe Size | Thread Type | Gender | Max. Pressure, psi | Gripping Force Factor | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | No. of | Dia. | Includes | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base—Single Acting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/4" | 3 1/8" | Steel | Smooth | Yes | 1/4 | NPSM | Male | 120 | 15 | 5 3/8" | 10 1/4" | Iron | Bolt On | No | 4 | 17/32" | Two 5-ft. Long Air Hoses | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 5/16" | 4 5/8" | Steel | Smooth | Yes | 1/4 | NPSM | Male | 120 | 15 | 5 3/8" | 13 1/2" | Iron | Bolt On | No | 4 | 21/32" | Two 5-ft. Long Air Hoses | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base—Double Acting | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 1 1/4" | 3 1/8" | Steel | Smooth | Yes | 1/4 | NPSM | Male | 120 | 15 | 5 3/8" | 13 11/16" | Iron | Bolt On | No | 4 | 17/32" | Three 5-ft. Long Air Hoses | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 5/16" | 5" | Steel | Smooth | Yes | 1/4 | NPSM | Male | 120 | 15 | 5 3/8" | 18 1/4" | Iron | Bolt On | No | 4 | 21/32" | Three 5-ft. Long Air Hoses | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 2 1/2" | 7 3/8" | Steel | Smooth | Yes | 1/4 | NPSM | Male | 120 | 19 | 6 17/32" | 25 5/8" | Iron | Bolt On | No | 4 | 11/16" | Three 5-ft. Long Air Hoses | 0000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||