Filter by

Vise Type

For Machine Type

System of Measurement

Mount Type

Base Type

DFARS Specialty Metals

Jaw Replaceable

Material

Export Control Classification Number (ECCN)

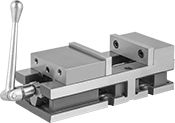

Compact Milling-Machine Vises

With Dovetail and Flat Jaws

|  |  |

Fixed Base 2 15/16" Wide Jaw | Fixed Base 4 15/16" Wide Jaw | 45° Dovetail Angle |

Jaw | Dovetail | Body | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Wd. | Ht. | Max. Opening | Step Ht. | Material | Texture | Replaceable | Centering Accuracy | Ht. | Angle | Overall Ht. | Lg. | Material | Mount Type | Mounting Fasteners Included | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 15/16" | 13/16" | 3" | 0.1" | Steel | Smooth, Serrated | Yes | 0.0005" | 0.1" | 45° | 2 7/32" | 3 15/16" | Steel | Bolt On | Yes | Stepped Jaws | 000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 15/16" | 1 9/32" | 3 1/16" | 0.1" | Steel | Smooth, Serrated | Yes | 0.0005" | 0.1" | 45° | 2 29/32" | 6" | Steel | Bolt On | No | Stepped Jaws | 000000 | 00000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

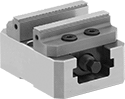

High-Precision Milling-Machine Vises

With Flat Jaws

|  |

Jaws attached to the outside ends of jaw holders extend the opening |

Vises | Replacement Handles | Repair Kits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Jaw | Body | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wd. | Ht. | Max. Opening | Material | Texture | Replaceable | Max. Extended Opening | Overall Ht. | Lg. | Material | Base/Bed Parallel Tolerance | Mount Type | Mounting Fasteners Included | Each | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 1 1/4" | 6" | Steel | Smooth | Yes | 12 1/4" | 3 5/8" | 12 5/8" | Iron | 0.0005" | Bolt On | No | 0000000 | 000000000 | 0000000 | 000000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6" | 1 3/4" | 6" | Steel | Smooth | Yes | 14 3/4" | 4 15/16" | 15 1/16" | Iron | 0.0005" | Bolt On | No | 0000000 | 00000000 | 0000000 | 00000 | 0000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

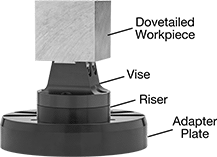

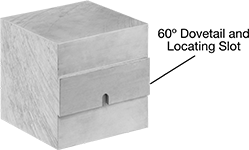

Dovetail Milling-Machine Vises

With Dovetail Jaws

For Max. Workpiece | Dovetail | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Lg. | Wd. | Ht. | Wt., lb. | Ht. | Angle | Dia. | Lg. | Wd. | Overall Ht. | Body Material | Clamp Material | Mounting Fasteners Included | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Fixed Base | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 13/16" | 5 13/16" | 5 13/16" | 18 | 1/8" | 60° | 4.97" | — | — | 3" | Aluminum | Stainless Steel | Yes | 000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 3/4" | 6 3/4" | 6 3/4" | 30 | 1/8" | 60° | 4.97" | — | — | 3" | Aluminum | Stainless Steel | Yes | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 10" | 10" | 80 | 3/16" | 60° | — | 5.95" | 5" | 2 1/2" | Aluminum | Stainless Steel | Yes | 000000 | 00000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||