Sanitary Energy-Saving Stainless Steel Steam Traps

When close to steam temperature, these traps—also called thermodynamic steam traps—release condensate from steam lines to save energy in food, pharmaceutical, and other sanitary environments. Made of 316 stainless steel, they stand up to frequent washdowns with harsh cleaners and sanitizers to reduce the risk of bacteria growth. They have quick-clamp tube fittings and a threaded cap, which are easy to remove for cleaning or access to your line.

Often used while equipment is operating at high pressures and temperatures, these steam traps don’t have plastic or rubber seals that can degrade over time. The lack of seals, however, means they may not last as long as other steam traps. Install these steam traps horizontally.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Gender | Pipeline Orientation | Pipe Connection Type | Max. Pressure, psi | Max. Temperature, °F | Condensate Capacity, lbs./hr. | Lg. | Ht. | Each | |

316 Stainless Steel | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | Horizontal | Quick Clamp | 225 | 800° | 1,050 | 2 9/16" | 2 3/8" | 0000000 | 0000000 |

Sanitary Stainless Steel Steam Traps

Suitable for food, pharmaceutical, and other sanitary environments, these steam traps are made of 316 stainless steel with a Viton® fluoroelastomer O-ring to stand up to frequent washdowns with harsh cleaners and sanitizers. They have a smooth 20Ra interior finish—smoother than most food and dairy applications require—and a self-draining design to reduce the risk of bacteria growth. They also have quick-clamp tube fittings, which are easy to remove for cleaning and access to your line. The O-ring is FDA compliant for direct contact with food.

Use these steam traps to increase the efficiency of your radiator by venting cool air. Also known as thermostatic steam traps, they automatically open and close based on temperature. Install them with their outlet pointing down.

For technical drawings and 3-D models, click on a part number.

| Pipe Size | Gender | Pipeline Orientation | Connection Style | Max. Pressure, psi | Max. Temp., °F | Condensate Capacity, lbs./hr. | Lg. | Ht. | Dia. | Specifications Met | Each | |

316 Stainless Steel | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1/2 | Female | Vertical | Quick Clamp | 90 | 350° | 2,580 | 2 5/8" | 2 5/8" | 1" | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 |

| 3/4 | Female | Vertical | Quick Clamp | 90 | 350° | 2,580 | 2 5/8" | 2 5/8" | 1" | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 1 | Female | Vertical | Quick Clamp | 90 | 350° | 2,580 | 2 5/8" | 2 5/8" | 2" | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

Sanitary Metal Filter Housings with Cartridge

for Food and Beverage Steam Lines

Remove contaminants, moisture, and other particles from steam that will touch food and for final filtering in pharmaceutical, biotech, and electronics applications. The cartridge in these housings filters out 98% of particles as small as 1 micron and 100% of particles as small as 2 microns. That’s why they meet 3-A’s accepted practice for creating culinary-grade steam, which is often used in steam-in-place (SIP) cycles to sanitize equipment, and for applications such as blanching. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

All are made of 316 stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them, and they withstand steam. These housings are designed to sanitary standards; they’re 3-A certified 10-04 and meet ASME BPE. They have rounded edges and highly polished interior and exterior surfaces, minimizing the spots where bacteria could grow. For the same reason, they don’t have horizontal ledges—liquid completely drains off.

They connect to your line with two quick-clamp fittings that are easy to take apart for cleaning and line reconfiguration. Each fitting is tightly sealed with an EPDM gasket, which has excellent resistance to steam.

Cartridges can be cleaned and reused, but after six cleanings you should replace them to maintain high performance.

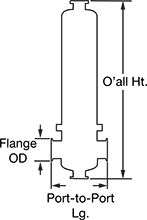

Filter Housings with Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Removes Particle Size Down To, microns | Replacement Cartridges | |||||||||||||

| For Tube OD | Flange OD | Steam Capacity | 98% Efficiency | 100% Efficiency | Max. Pressure, psi | Max. Temp., °F | Cartridge Useful Life | Port-to-Port Length | Overall Height | Specifications Met | Each | Each | ||

Quick Clamp Tube Vent and Drain | ||||||||||||||

316 Stainless Steel Housing and Cartridge | ||||||||||||||

| 1/2" | 0.984" | 100 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 4 23/32" | 9" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 | 0000000 | 0000000 |

| 1" | 1.984" | 400 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 14 1/2" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 000000 |

| 2" | 1.984" | 800 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 19 3/4" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 00000000 |