Filter by

Screw Size

Thickness

Specifications Met

Washer Designation

Performance

Passivation

Maximum Temperature

Fastener Strength Grade/Class

DFARS Specialty Metals

Hardness

Minimum Temperature

Sold As

General Purpose Washers

Your go-to metal washer for every screw size. Washers take the pressure off nuts and screws to protect mounting surfaces.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Fastener Strength Grade/Class—If you require screws or nuts with a specific fastener strength rating, make sure your washer matches the grade or class.

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fastener Strength Grade/Class | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | — | DIN 125, ISO 7089 | 100 | 91166A180 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | ISO Class 8.8 | DIN 125, ISO 7089 | 100 | 91455A310 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.3 to 0.4 | ISO Class 10.9 | DIN 125, ISO 7089 | 100 | 98688A147 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.3 to 0.4 | — | DIN 125, ISO 7089 | 50 | 98687A301 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.3 to 0.4 | — | DIN 125 | 100 | 98687A131 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Aluminum%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

One-third the weight of steel, these washers are commonly used in robotics, automation, and other applications that have weight limits. They're an alternative to stainless steel for rust resistance, but aren't as strong.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | DIN 125, ISO 7089 | 10 | 92334A107 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass

|

Softer than most metals, brass washers won't damage other fastening components.

Brass—With a warm, polished look, these washers are often chosen for their appearance. Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | DIN 125, ISO 7089 | 100 | 91635A170 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Washers

|

All of these washers are lightweight, nonconductive, and naturally rust resistant. They are commonly used in electronics and automation applications to take the pressure off screws and nuts and protect mounting surfaces.

Nylon—The most popular plastic washers, these are strong, durable, and economical. Nylon will swell and weaken when exposed to moisture, so these washers are best for dry environments.

Low-Friction Lubricant-Filled Nylon—Reduce friction between the washer, fastener, and mounting surface to prevent sticking when tightening and loosening.

Moisture-Resistant Delrin® Acetal—The best plastic for damp and wet environments, these washers won't swell or lose their strength if exposed to moisture.

Clear Impact-Resistant Polycarbonate—Withstand bumps and vibration without cracking or denting. These washers are also clear to be less noticeable in your assembly.

Low-Friction Impact-Resistant UHMW Polyethylene—The slippery surface reduces friction between the washer, fastener, and mounting surface to prevent sticking when fastening and loosening. These washers also resist bumps and vibration without cracking or denting.

Acid-Resistant PVC—A great choice for chemical-processing lines, these washers won't degrade when exposed to harsh acids, alkalis, and alcohols. They are also good electrical insulators.

Chemical-Resistant Polypropylene—These versatile washers resist a broad range of chemicals, such as petroleum, degreasers, and methyl ethyl ketone (MEK). They will weaken, however, if exposed to chlorine, lacquer solvents, or nitric acid.

Chemical-Resistant High-Temperature PTFE—The most chemical-resistant plastic washers we offer, these stand up to the widest range of harsh acids, bases, solvents, and corrosive cleaners, even at temperatures up to 500° F. Their slippery surface reduces friction between the washer, fastener, and mounting surface to prevent sticking when tightening and loosening. They are also good electrical insulators.

High-Strength High-Temperature PEEK—These washers bear heavier loads than most other plastic washers. In addition, they won't melt or deform when exposed to high temperatures up to 550° F. PEEK washers aren't very impact resistant, however, so they may crack or dent if subjected to hard bumps and vibrations.

Extreme-Strength High-Temperature Carbon-Filled PEEK—Second only to phenolic in terms of strength, these washers stand up to high-stress applications. They won't melt or deform when exposed to high temperatures up to 500° F.

Electrically Insulating Ultem PEI—Our best electrical insulators, these washers are often used to secure components in circuit-breaker housings and semiconductors.

Extreme-Strength Electrically Insulating Phenolic— A close alternative to metal, these are the strongest of all our plastic washers and won't weaken, even when exposed to moisture. They protect components from unintentional electrical charges to prevent short circuits.

Temp. Range, ° F | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Min. | Max. | Specs. Met | Choose a Color | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.6 to 1.0 | -40 | 180 | — | Black | 100 | 95610A310 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.6 to 1.0 | -40 | 180 | — | Off-White | 100 | 95610A110 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | -40 | 220 | DIN 9021 | Off-White | 25 | 95610A113 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Friction Lubricant-Filled Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | Not Rated | 220 | DIN 125 | Gray | 5 | 91545A410 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture-Resistant Delrin® Acetal | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.7 to 0.9 | Not Rated | 180 | — | White | 10 | 95647A151 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Clear Impact-Resistant Polycarbonate | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.1 | 4.0 | 0.4 to 0.6 | Not Rated | 212 | — | Clear | 50 | 90940A411 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | -40 | 220 | DIN 125 | Clear | 10 | 90940A105 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Low-Friction Impact-Resistant UHMW Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.1 | 5.0 | 0.7 to 0.9 | Not Rated | 180 | — | Off-White | 10 | 95649A310 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Acid-Resistant PVC | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.1 | 5.0 | 0.7 to 0.9 | Not Rated | 140 | — | Gray | 10 | 95611A102 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant Polypropylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5 | 0.7 to 0.9 | Not Rated | 150 | — | Off-White | 10 | 98594A311 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Chemical-Resistant High-Temperature PTFE | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.7 to 0.9 | Not Rated | 500 | — | White | 50 | 95630A610 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength High-Temperature PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | -20 | 500 | DIN 125 | Beige , Black | 10 | 93785A410 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Strength High-Temperature Carbon-Filled PEEK | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | -20 | 500 | DIN 125 | Black | 10 | 93785A711 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Electrically Insulating Ultem PEI | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.2 to 0.4 | -30 | 450 | DIN 125 | Beige , Black | 10 | 95331A100 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Extreme-Strength Electrically Insulating Phenolic | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5 | 0.7 to 0.9 | Not Rated | 250 | — | Brown | 10 | 91225A111 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Undersized Washers

These washers distribute pressure evenly under fasteners with narrow heads, such as cheese and socket head screws. They have smaller diameters than general purpose washers of the same screw size.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 4.5 | 0.2 to 0.4 | DIN 433, ISO 7092 | 100 | 98688A110 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Brass

|

Softer than most metals, brass washers won't damage other fastening components.

Brass—With a warm, polished look, these washers are often chosen for their appearance. Similar to 18-8 stainless steel, brass is corrosion resistant enough to stand up to wet environments.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Brass | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 4.5 | 0.2 to 0.4 | DIN 433, ISO 7092 | 100 | 98691A111 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oversized Washers

These washers have exaggerated diameters to cover large holes and to compensate for uneven mounting surfaces. They are also thicker than general purpose washers, so they bridge wide gaps when used as spacers.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these washers have a dark, matte coating to create a finished look. They resist rust in wet and outdoor environments, but won't hold up to harsh chemicals as well as 316 stainless steel.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

High-Strength 17-7 PH Stainless Steel—Some of the strongest stainless steel washers we offer, these are comparable to high-strength Grade 8 steel. They won’t rust in wet and outdoor environments, but they can’t handle the harsh chemicals that 316 stainless steel can.

For Screw Size | ID, mm | OD, mm | Thk., mm | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | 100 | 91116A240 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | 10 | 91116A310 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | 100 | 95211A260 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Strength 17-7 PH Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | 10 | 91860A060 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel

|

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

For Screw Size | ID, mm | OD, mm | Thk., mm | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 7.0 | 0.6 to 1.0 | 50 | 98688A191 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Self-Retaining Washers

|

Save time by assembling screws and washers in advance. The tabs on these washers grip the screw shank, so they won't slip off, even when fastening upside down or at odd angles. They take the pressure off screws and nuts to protect mounting surfaces.

Nylon—The most popular plastic washers, these are strong, durable, and economical. Nylon will swell and weaken when exposed to moisture, so these washers are best for dry environments.

Insulating Sleeve Washers

Cover screw threads to stop electrical current in its tracks and prevent short circuits. These washers create a barrier between the screw threads and the mating surface when mounted in through holes. This barrier also extends the life of your assembly by preventing galvanic corrosion, which is when two different metals rust more quickly due to contact with each other.

Flat Edge

|

The flat edge distributes weight evenly to take pressure off screw heads.

Nylon—Our most versatile insulating washers, these block unwanted current in everything from switches and circuit breakers to control panels and electric motors.

Very-High-Temperature Ceramic—Our most heat-resistant washers and the best electrical insulators. These won't melt or become brittle at blistering temperatures up to 1,700° F, making them perfect for ovens, kilns, and furnaces. Ceramic may crack or dent if subjected to hard bumps, however, so these washers are not recommended for high-vibration applications.

Ultra-High-Temperature Ceramic Washers

|

Our most heat-resistant washers, even at blistering temperatures up to 3000° F. They distribute pressure evenly under nuts and screws in industrial furnaces, kilns, and other extreme-temperature environments. Ceramic may crack or dent if subjected to hard bumps, however, so these washers are not recommended for high-vibration applications.

Temp. Range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Min. | Max., ° F | Specs. Met | Color | Each | ||

| M2 | 2.6 | 6.0 | 0.6 to 0.9 | Not Rated | 3,000 | ASME B18.22M | Off-White | 94610A420 | 00000 | |

Split Lock Washers

|

Stop nuts and screws from loosening due to mild vibration. As you tighten, the uneven ends bite into the nut or screw so it won't back out. While they're not as vibration resistant as other lock washers, they are a great fit for electrical panels, light fixtures, and other light duty assemblies. Split lock washers are not reusable, and they only work with fasteners that have right-hand threads.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Black-Oxide 18-8 Stainless Steel—Typically chosen for their appearance, these washers have a dark, matte coating to create a finished look. They won't rust in wet and outdoor environments, but can't hold up to harsh chemicals as well as 316 stainless steel.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.4 | 4.4 | 0.4 to 0.6 | DIN 127B | 100 | 92148A050 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black-Oxide 18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.4 | 4.4 | 0.4 to 0.6 | DIN 127B | 10 | 92148A331 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.4 | 4.4 | 0.4 to 0.6 | DIN 127B | 100 | 92153A406 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.4 | 4.4 | 0.4 to 0.6 | DIN 127B | 100 | 91202A214 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.4 | 4.4 | 0.4 to 0.6 | DIN 127B | 100 | 91169A050 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

High-Pressure Bonded Sealing Washers

Tested to hold up to high pressures, these washers create the strongest seal of all to lock in air and fluid and keep equipment running efficiently. They are often used on flanged connections to prevent leaks in pumps, hydraulic systems, compressors, and other pressurized lines. The flexible rubber or plastic layer compresses to fills gaps, while the metal backing stops the washer from squeezing through the hole.

For Screw Heads

|

|

Fit under screw heads to stop leaks. These washers seal best on screws that aren't threaded all the way up to the head. Reuse them a handful of times, as long as the material isn't damaged.

Oil-Resistant Zinc-Plated Steel and Buna-N—These washers won't swell or soften when they touch oil, grease, and fuel. However, they will degrade if exposed to synthetic lubricants. They are also are more susceptible to rusting than 18-8 and 316 stainless steel.

Max. Pressure, psi | Temp. Range, ° F | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | For Fluids | For Gases | Min. | Max. | Color | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oil-Resistant Zinc-Plated Steel and Buna-N | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 1.8 | 4.5 | 0.9 to 1.1 | 7,300 | 200 | -10 | 240 | Black | 10 | 93786A501 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tooth Lock Washers

Grip tighter than split lock washers to prevent nuts and screws from loosening in applications with constant movement, such as conveyors. Tooth lock washers typically can't be reused because the teeth often get bent when tightened.

External Tooth

|

Teeth on the outside edge bite into both the fastener and the mating surface for a stronger hold than internal-tooth lock washers. However, they may mar your material and snag on objects. Pair these washers with nuts and screws that are large enough to make contact with the teeth, such as pan, button, and binding head screws.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

DIN 6798—Best for slightly bumpy or irregular surfaces because the teeth are angled to make even contact with the material.

Internal Tooth

|

Internal teeth dig into the nut or screw to prevent it from backing out. Unlike external-tooth lock washers, these have a smooth outside edge, so they are less likely to mar your material or snag on objects. However, they don’t grip quite as well. Pair them with fasteners that have small diameters, such as fillister and cheese head screws.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Black-Oxide Steel—Typically chosen for their appearance, these washers have a dark, matte coating that creates a finished look. They offer minimal corrosion resistance, so they're best for dry environments.

Sealing Washers

Prevent leaks while distributing weight evenly under nuts and screws. These washers compress as you tighten to keep air and fluid in, and dust and contaminants out. Use them anywhere you need a tight seal, such as protecting electronics from moisture or keeping lubricants contained in machinery.

Metal

|

Also known as crush washers, these are made of soft metal that deforms under pressure to fill gaps around the nut or screw. Often found in oil drain valves, they withstand stress and wear better than plastic and rubber washers, but aren't as leak-resistant. Metal sealing washers are not reusable.

Copper—Softer than aluminum washers, these deform easily to create a tight seal with less effort. They resist rusting in corrosive environments, but will develop a green patina over time.

For Screw Size | ID, mm | OD, mm | Thk., mm | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Copper | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.200 | 5.600 | 0.6 to 0.9 | 25 | 97725A239 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Vibration-Resistant Spring Lock Washers

|

With a grip that's second only to wedge lock, these washers stop nuts and screws from wiggling loose under constant, vigorous vibration. They are ideal for engines, turbines, generators, and other heavy duty equipment. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Super-Corrosion-Resistant 316 Stainless Steel—Superior to 18-8 stainless steel, these washers won't degrade when exposed to harsh weather, salt water, and most chemicals.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Phosphate-Coated Steel—Paint adheres evenly to the surface of these washers, so you can add your own decorative finish. They are more durable than zinc-plated steel washers to withstand wet and outdoor environments. However, they won't hold up to the harsh chemicals that stainless steel can.

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Specs. Met | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 50 | 91477A122 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Corrosion-Resistant 316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 25 | 93237A101 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Zinc-Plated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 95221A101 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Phosphate-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 95221A200 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 5.0 | 0.4 | 0.6 | DIN 6796 | 100 | 93497A100 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hard Fiber Washers

|

The least likely to scratch or mar delicate mounting surfaces, these washers are made of hardened cotton fiber. They are also naturally nonconductive, so they are a great choice for insulating nuts and screws to prevent unintended charges. However, fiber washers will break down faster than other washers and will need to be replaced more often.

For Screw Size | ID, mm | OD, mm | Thk., mm | Specs. Met | Color | Pkg. Qty. | Pkg. | ||

|---|---|---|---|---|---|---|---|---|---|

| M2 | 2.3 | 5 | 0.3 to 0.4 | DIN 125 | Black | 25 | 95225A210 | 000000 |

Wave Spring Lock Washers

|

The wavy shape flexes like a spring to keep nuts and screws secure on slightly uneven surfaces. These washers add a small amount of tension to stop fasteners from backing out due to mild vibration. While they don't hold as well as other lock washers, they do grip slightly better than curved washers. They work best in electrical panels, light fixtures, and other light duty assemblies. Since these washers hold their shape when untightened, you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

3 Wave—More points of contact than single-wave washers for a better grip.

For Screw Size | No. of Waves | ID, mm | OD, mm | Thk., mm | Overall Ht., mm | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 3 | 2.4 | 4.2 | 0.3 | 0.9 | 10 | 92161A047 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

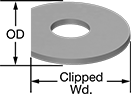

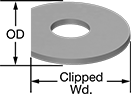

Clipped Washers

Clipped on one side, these washers fit in tight spots where your typical round washers can't. Position them against a flat edge, and they won't rotate out of place as you tighten. Washers take the pressure off screws and nuts to protect mounting surfaces.

Stainless Steel%20--%3e%3csvg%20version='1.1'%20id='Layer_1'%20xmlns='http://www.w3.org/2000/svg'%20xmlns:xlink='http://www.w3.org/1999/xlink'%20x='0px'%20y='0px'%20viewBox='0%200%20400%20400'%20style='enable-background:new%200%200%20400%20400;'%20xml:space='preserve'%3e%3cstyle%20type='text/css'%3e%20.st0{fill:%231A70A0;}%20.st1{opacity:0.5;}%20%3c/style%3e%3cg%3e%3cg%3e%3cpath%20class='st0'%20d='M200,56.9c38.35,0,74.4,14.93,101.51,42.05c27.11,27.11,42.05,63.17,42.05,101.51s-14.93,74.4-42.05,101.51%20S238.35,344.02,200,344.02s-74.4-14.93-101.51-42.05c-27.11-27.11-42.05-63.17-42.05-101.51s14.93-74.4,42.05-101.51%20S161.65,56.9,200,56.9%20M200,12.9C96.41,12.9,12.44,96.88,12.44,200.46c0,103.59,83.97,187.56,187.56,187.56%20c103.59,0,187.56-83.97,187.56-187.56C387.56,96.88,303.59,12.9,200,12.9L200,12.9z'/%3e%3c/g%3e%3cg%3e%3cg%20class='st1'%3e%3cpath%20class='st0'%20d='M235.49,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C190.89,163.58,214.53,158.88,235.49,152.24z%20M230.44,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C218.68,82.23,224.24,80.84,230.44,80.84z'/%3e%3c/g%3e%3cg%3e%3cpath%20class='st0'%20d='M214.08,152.24h16.15l-27.46,111.87c-1.94,7.8-2.91,12.5-2.91,14.1c0,1.82,0.58,3.29,1.73,4.41%20c1.16,1.12,2.69,1.68,4.61,1.68c5.23,0,11.78-3.85,19.63-11.55l17.22,21.34c-16.95,17.33-34.87,26-53.78,26%20c-8.37,0-15.45-1.47-21.23-4.41c-5.79-2.94-10.44-7.25-13.95-12.92c-3.51-5.67-5.27-11.18-5.27-16.53c0-1.93,0.35-5.24,1.05-9.94%20c1-6.94,2.05-12.54,3.15-16.82l15.22-62.15h-32.69l7.65-30.97C169.48,163.58,193.11,158.88,214.08,152.24z%20M209.03,80.84%20c8.24,0,14.66,2.62,19.26,7.86c4.6,5.24,6.9,11.55,6.9,18.94c0,5.46-1.42,10.7-4.25,15.73c-2.83,5.03-6.88,9.07-12.12,12.12%20c-5.24,3.05-10.33,4.57-15.24,4.57c-4.6,0-9.17-1.23-13.72-3.69c-4.55-2.46-8.02-5.78-10.43-9.95%20c-2.41-4.17-3.61-8.67-3.61-13.48c0-5.35,1.52-10.64,4.57-15.89c3.05-5.24,7.03-9.25,11.96-12.04%20C197.26,82.23,202.83,80.84,209.03,80.84z'/%3e%3c/g%3e%3c/g%3e%3c/g%3e%3c/svg%3e)

|

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers resist rust. However, they won't hold up to the harsh chemicals that 316 stainless steel can.

For Screw Size | ID, mm | OD, mm | Clipped Wd., mm | Thk., mm | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

18-8 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 4.5 | 3.9 | 0.2 to 0.4 | 5 | 96025A268 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel

|

Steel—Best for dry environments since moisture will cause these washers to rust.

For Screw Size | ID, mm | OD, mm | Clipped Wd., mm | Thk., mm | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| M2 | 2.2 | 4.5 | 3.9 | 0.2 to 0.4 | 5 | 96025A235 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heavy-Vibration-Resistant Spring Lock Washers for Socket Head Screws

|

Stop socket head screws from wiggling loose on equipment with constant, vigorous vibration, such as engines, turbines, and generators. These washers have a small diameter to fit under screws with narrow heads. Similar to a spring, they flatten under pressure to add tension between mating surfaces. As long as the washers aren't deformed or otherwise damaged, you can reuse them indefinitely without losing locking strength. Also known as conical washers and Belleville washers.

Stack multiple washers in the same direction to double or triple how much weight they can bear. Stack washers in opposite directions for better deflection, which means they compress further and withstand more shock and movement without loosening.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Steel—Best for dry environments since moisture will cause these washers to rust.

Top-and-Bottom Serration—Adds friction for extra gripping power.

Curved Spring Lock Washers

|

The curvy, spring-like shape adds a small amount of tension to prevent nuts and screws from backing out due to mild vibration. These washers also flex slightly to compensate for uneven surfaces. While more secure than a standard flat washer, these have the least amount of gripping power of all our lock washers. They are best suited for electrical panels, light fixtures, and other light duty assemblies. These washers hold their shape when untightened, so you can reuse them a handful of times without losing strength.

18-8 Stainless Steel—The choice for wet and outdoor environments, these washers won't rust when exposed to moisture. However, they can't hold up to the harsh chemicals that 316 stainless steel can.

Zinc-Plated Steel—A common choice for areas with occasional exposure to moisture.

Fiberglass Washers

|

A lightweight alternative to stainless steel, these fiberglass washers have the best strength-to-weight ratio of all our nonmetal washers. Commonly used to distribute pressure under nuts and screws in building frames, they are a great fit when you need something more robust than plastic, but still have to stay within a certain weight limit.

Temp. Range | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

For Screw Size | ID, mm | OD, mm | Thk., mm | Min. | Max., ° F | Color | Pkg. Qty. | Pkg. | ||

| M2 | 2.2 | 5.0 | 0.7 to 0.9 | Not Rated | 280 | Light Green | 10 | 93493A311 | 000000 | |