Plastic Filter Housings with Cartridge for Reducing Sediment and Rust in Water

These filter housings come with a cartridge that filters rust and sediment from your water line. They have a pressure-relief valve that allows you to release pressure prior to replacing the cartridge.

Opaque filter housings are light-blocking to minimize algae growth.

Clear filter housings let you monitor debris collecting in the cartridge without stopping flow.

Filter housings with flow-control valve allow you to stop the flow to replace the cartridge.

Filter Housings with Cartridge | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cartridge | Replacement Cartridges | Replacement O-Rings | Mounting Brackets | Replacement Bowls | |||||||||||||

| Pipe Size | Thread Type | OD | Ht. | Max. Flow Rate, gpm | Max. Pressure, psi | Removes Particle Size Down To, microns | Features | Each | Each | Each | Each | Each | |||||

Filter Housings with Cartridge | |||||||||||||||||

Opaque Blue Polypropylene Plastic Housing | |||||||||||||||||

| 1/4 | NPT | 2 1/2" | 9 7/8" | 10 | 100 | 20 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 00000 | 000000 | 00 |

| 3/8 | NPT | 2 3/8" | 4 7/8" | 2 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 000000 |

| 1/2 | NPT | 2 1/2" | 9 7/8" | 10 | 100 | 20 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 | 000000 | 00 |

| 3/4 | NPT | 2 5/8" | 9 3/4" | 10 | 125 | 20 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 00000 | 00000000 | 00000 |

| 3/4 | NPT | 2 5/8" | 20" | 10 | 125 | 20 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 00000000 | 00000 |

| 3/4 | NPT | 4 1/2" | 20" | 20 | 90 | 20 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 000000 | 00 |

| 1 | NPT | 4 1/2" | 9 3/4" | 10 | 100 | 50 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 |

| 1 | NPT | 4 1/2" | 20" | 20 | 90 | 20 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 000000 | 00 |

| 1 1/2 | NPT | 4 1/2" | 9 3/4" | 10 | 100 | 50 | Pressure-Relief Valve | 00000000 | 00000 | 00000000 | 00000 | 0000000 | 00000 | 00000000 | 00000 | 000000000 | 00000 |

| 1 1/2 | NPT | 4 1/2" | 20" | 20 | 90 | 20 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 000000 | 00 |

Clear Polystyrene Plastic Housing | |||||||||||||||||

| 1/4 | NPT | 2 5/8" | 9 3/4" | 10 | 125 | 20 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 |

| 3/8 | NPT | 2 3/8" | 4 7/8" | 2 | 125 | 5 | Pressure-Relief Valve | 000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 00000 |

| 1/2 | NPT | 2 5/8" | 9 3/4" | 10 | 125 | 20 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 | 00000000 | 00000 |

| 3/4 | NPT | 2 3/8" | 9 7/8" | 8 | 125 | 5 | Flow-Control Valve Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 00000 | 0000000 | 00000 |

| 3/4 | NPT | 2 5/8" | 9 3/4" | 10 | 125 | 20 | Pressure-Relief Valve | 000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 00000 | 0000000 | 00000 |

| 3/4 | NPT | 2 3/4" | 20" | 20 | 150 | 20 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 00000000 | 00000 |

| 1, 1 1/2 | NPT | 4 1/2" | 10" | 15 | 100 | 50 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 00000000 | 000000 |

| 1, 1 1/2 | NPT | 4 1/2" | 20" | 25 | 100 | 50 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 | 00000000 | 000000 |

Plastic Filter Housings with Cartridge for Reducing Odor and Chlorine in Water

These filter housings come with a cartridge that filters odor and chlorine from your water line. They have a pressure-relief valve that allows you to release pressure prior to replacing the cartridge.

Opaque filter housings are light-blocking to minimize algae growth.

Clear filter housings let you monitor debris collecting in the cartridge without stopping flow.

Filter housings with flow-control valve allow you to stop the flow to replace the cartridge.

Filter housings with compression tube fitting adapters let you connect to tubing (sold separately) so you can route flow around a clogged cartridge.

Filter Housings with Cartridge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cartridge | Replacement Cartridges | Replacement O-Rings | Mounting Brackets | ||||||||||||

| Pipe Size | Thread Type | OD | Ht. | Max. Flow Rate, gpm | Max. Pressure, psi | Removes Particle Size Down To, microns | Features | Each | Each | Each | Each | ||||

Filter Housings with Cartridge | |||||||||||||||

Opaque Blue Polypropylene Plastic Housing | |||||||||||||||

| 1/4 | NPT | 2 7/8" | 9 3/4" | 4 | 100 | 5 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| 3/8 | NPT | 2 1/2" | 4 7/8" | 2 | 125 | 5 | Pressure-Relief Valve | 000000 | 00000 | 00000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 |

| 1/2 | NPT | 2 7/8" | 9 3/4" | 4 | 100 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 |

| 3/4 | NPT | 2 1/2" | 20" | 5 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 |

| 3/4 | NPT | 4 5/8" | 20" | 8 | 90 | 5 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 |

| 1 | NPT | 4 1/2" | 9 3/4" | 2 | 100 | 25 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 00000 | 0000000 | 00000 | 00000000 | 00000 |

| 1 | NPT | 4 5/8" | 20" | 8 | 90 | 5 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 |

| 1 1/2 | NPT | 4 5/8" | 20" | 8 | 90 | 5 | Pressure-Relief Valve | 00000000 | 000000 | 00000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 |

Clear Polystyrene Plastic Housing | |||||||||||||||

| 1/4 | NPT | 2 7/8" | 9 3/4" | 4 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 |

| 3/8 | NPT | 2 1/2" | 4 7/8" | 2 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 00000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 |

| 1/2 | NPT | 2 7/8" | 9 3/4" | 4 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 0000 |

| 3/4 | NPT | 2 1/2" | 9 3/4" | 5 | 125 | 5 | Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 0000 | 0000000 | 00000 |

| 3/4 | NPT | 2 5/8" | 20" | 8 | 150 | 3 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 |

| 3/4 | NPT | 2 3/4" | 20" | 1 | 150 | 1 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 0000 | 0000000 | 00000 |

| 1, 1 1/2 | NPT | 4 1/2" | 20" | 2 | 100 | 5 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 |

| 1, 1 1/2 | NPT | 4 1/2" | 20" | 3 | 100 | 1 | Pressure-Relief Valve | 0000000 | 000000 | 0000000 | 000000 | 0000000 | 0000 | 0000000 | 00000 |

Filter Housings with Cartridge and Two 3/4" Compression Tube Fitting Adapters | |||||||||||||||

Clear Polystyrene Plastic Housing | |||||||||||||||

| 3/4 | NPT | 2 1/2" | 9 3/4" | 5 | 125 | 5 | Flow-Control Valve Pressure-Relief Valve | 0000000 | 00000 | 0000000 | 00000 | 000000 | 00 | 000000 | 00 |

Plastic Filter Housings with Cartridge for

Reducing Oil, Gasoline, and Diesel Fuel in Water

This filter housing comes with a cartridge that filters oil, gasoline, and diesel fuel from your water line. It is opaque white so it blocks light to minimize algae growth. It has a pressure-relief valve that allows you to release pressure prior to replacing the cartridge.

Filter Housings with Cartridge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cartridge | Replacement Cartridges | Replacement O-Rings | Mounting Brackets | ||||||||||||

| Pipe Size | Thread Type | OD | Ht. | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Removes Particle Size Down To, microns | Each | Each | Each | Each | ||||

Opaque Polypropylene Plastic Housing | |||||||||||||||

| 3/4 | NPT | 2 1/2" | 9 3/4" | 4 | 100 | 100° | 5 | 0000000 | 0000000 | 0000000 | 000000 | 0000000 | 00000 | 0000000 | 00000 |

| Head Dia. | Overall Lg. | Material | Each | |

| 4 3/4" | 9" | Polypropylene Plastic | 0000000 | 00000 |

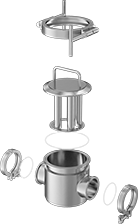

Corrosion-Resistant Metal Filter Housings

Use these filter housings with a cartridge (sold separately) to filter contaminants from liquids. They offer protection from corrosive environments.

Filter housings with clamp-on cover permit easy access to the cartridge for quick replacements.

Filter housings with pressure gauges indicate when it’s time to replace a dirty cartridge.

304 stainless steel filter housings offer very good corrosion resistance. 316 stainless steel filter housings have excellent corrosion resistance.

30 3/4" filter cartridges have O-ring end caps that prevent liquids from moving through the filter housing without passing through the cartridge.

Replacement gaskets for style A and style B housings include a cap nut gasket and shell gasket. Both gaskets must be replaced in order to create a new seal on the housing.

For Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Each | ||

| A | 1/2 | NPT | Female | 3 3/4" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 1.75 | 250 | 275° | Drain | 00000000 | 0000000 |

| A | 3/4 | NPT | Female | 9 3/4" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 7 | 250 | 275° | Drain | 00000000 | 000000 |

| A | 3/4 | NPT | Female | 20" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 14 | 250 | 275° | Drain | 00000000 | 000000 |

For Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Each | ||

| A | 3/4 | NPT | Female | 9 3/4" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 7 | 250 | 275° | Drain | 00000000 | 0000000 |

| A | 3/4 | NPT | Female | 20" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 14 | 250 | 275° | Drain | 00000000 | 000000 |

| A | 1 | NPT | Female | 9 3/4" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 7 | 250 | 275° | Drain | 00000000 | 000000 |

| A | 1 | NPT | Female | 20" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 14 | 250 | 275° | Drain | 00000000 | 000000 |

For Cartridge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Includes | Each | ||

| C | 1 | NPT | Female | 9 3/4"-10" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 7 | 300 | 200° | Drain | Mounting Bracket | 0000000 | 0000000 |

| C | 1 | NPT | Female | 9 3/4"-10" | 4 1/2" | 1" | Open on Both Ends | 1 | 20 | 150 | 200° | Drain | __ | 0000000 | 000000 |

| C | 1 | NPT | Female | 20" | 2"-2 3/4" | 1" | Open on Both Ends | 1 | 14 | 300 | 200° | Drain | Mounting Bracket | 0000000 | 000000 |

| C | 1 1/2 | NPT | Female | 20" | 4 1/2" | 1" | Open on Both Ends | 1 | 25 | 150 | 200° | Drain | __ | 0000000 | 000000 |

For Cartridge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Includes | Each | ||

| C | 1 | NPT | Female | 9 3/4"-10" | 2"-2 3/4" | 1" | O-Ring End Caps | 1 | 7 | 300 | 200° | Drain | Mounting Bracket | 000000 | 0000000 |

| C | 1 | NPT | Female | 20" | 2"-2 3/4" | 1" | O-Ring End Caps | 1 | 14 | 300 | 200° | Drain | Mounting Bracket | 000000 | 000000 |

| Replacement Gasket | 0000000 | Each | 00000 |

For Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Each | ||

| D | 2 | NPT | Male | 9 3/4"-10" | 2"-2 3/4" | 1" | Open on Both Ends | 4 | 28 | 150 | 300° | Drain Clamp-On Cover | 00000000 | 000000000 |

| D | 2 | NPT | Male | 19 1/2"-20" | 2"-2 3/4" | 1" | Open on Both Ends | 4 | 56 | 150 | 300° | Drain Clamp-On Cover | 00000000 | 00000000 |

| D | 2 | NPT | Male | 29 1/4"-30" | 2"-2 3/4" | 1" | Open on Both Ends | 4 | 84 | 150 | 300° | Drain Clamp-On Cover | 00000000 | 00000000 |

| D | 2 | NPT | Male | 39"-40" | 2"-2 3/4" | 1" | Open on Both Ends | 4 | 112 | __ | 280° | Drain Clamp-On Cover | 00000000 | 00000000 |

For Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | Max. OD | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Each | ||

| E | 2 | NPT | Male | 30 3/4" | 7 3/4" | 2 5/8" | O-Ring End Caps | 1 | 150 | 150 | 140° | Two Drains Clamp-On Cover Two Pressure Gauges | 0000000 | 000000000 |

For Cartridge | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Pipe Size | Thread Type | Gender | Ht. | OD | ID | End Type | Construction | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Features | Each | ||

| F | 1 1/2 | NPT | Male | 9 3/4" | 2 3/4" | 1" | Open on Both Ends | Pleated | 7 | 30 | 150 | 140° | Drain Bolt-On Cover | 0000000 | 000000000 |

| F | 1 1/2 | NPT | Male | 19 1/2" | 2 3/4" | 1" | Open on Both Ends | Pleated | 7 | 60 | 150 | 140° | Drain Bolt-On Cover | 0000000 | 00000000 |

| F | 2 | NPT | Male | 29 1/4" | 2 3/4" | 1" | Open on Both Ends | Pleated | 8 | 100 | 150 | 140° | Drain Bolt-On Cover | 0000000 | 00000000 |

| For Housing Style | Ht. | OD | ID | Removes Particle Size Down To, microns | End Type | Max. Flow Rate, gpm | Max.Temp., °F | O-Ring Material | Each | |

Polyester Plastic—String Wound | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| D | 40" | 2 1/2" | 1" | 5 | Open on Both Ends | 20 | 140° | __ | 000000000 | 000000 |

| F | 9 3/4" | 2 1/2" | 1" | 5 | Open on Both Ends | 5 | 140° | __ | 00000000 | 0000 |

| F | 19 1/2" | 2 1/2" | 1" | 5 | Open on Both Ends | 10 | 140° | __ | 00000000 | 00000 |

| F | 29 1/4" | 2 1/2" | 1" | 5 | Open on Both Ends | 15 | 140° | __ | 00000000 | 00000 |

Polypropylene Plastic—Pleated | ||||||||||

| E | 30 3/4" | 7 3/4" | 2 5/8" | 20 | O-Ring End Caps | 150 | 140° | EPR Rubber | 0000000 | 000000 |

| E | 30 3/4" | 7 3/4" | 2 5/8" | 50 | O-Ring End Caps | 150 | 140° | EPR Rubber | 0000000 | 000000 |

| E | 30 3/4" | 7 3/4" | 2 5/8" | 5 | O-Ring End Caps | 150 | 140° | EPR Rubber | 0000000 | 000000 |

Polypropylene Plastic—String Wound | ||||||||||

| D | 39 1/2" | 2 1/2" | 1" | 5 | Open on Both Ends | 20 | 140° | __ | 000000000 | 00000 |

| F | 9 3/4" | 2 1/2" | 1" | 5 | Open on Both Ends | 5 | 140° | __ | 00000000 | 0000 |

| F | 19 1/2" | 2 1/2" | 1" | 5 | Open on Both Ends | 10 | 140° | __ | 00000000 | 00000 |

| F | 29 1/4" | 2 1/2" | 1" | 5 | Open on Both Ends | 15 | 140° | __ | 00000000 | 00000 |

Sanitary Metal Filter Housings with Cartridge

for Food and Beverage Steam Lines

Remove contaminants, moisture, and other particles from steam that will touch food and for final filtering in pharmaceutical, biotech, and electronics applications. The cartridge in these housings filters out 98% of particles as small as 1 micron and 100% of particles as small as 2 microns. That’s why they meet 3-A’s accepted practice for creating culinary-grade steam, which is often used in steam-in-place (SIP) cycles to sanitize equipment, and for applications such as blanching. They’re FDA compliant for direct contact with food, and also meet pharmaceutical equipment design standards.

All are made of 316 stainless steel, so frequent washdowns with harsh cleaners and sanitizers won’t corrode them, and they withstand steam. These housings are designed to sanitary standards; they’re 3-A certified 10-04 and meet ASME BPE. They have rounded edges and highly polished interior and exterior surfaces, minimizing the spots where bacteria could grow. For the same reason, they don’t have horizontal ledges—liquid completely drains off.

They connect to your line with two quick-clamp fittings that are easy to take apart for cleaning and line reconfiguration. Each fitting is tightly sealed with an EPDM gasket, which has excellent resistance to steam.

Cartridges can be cleaned and reused, but after six cleanings you should replace them to maintain high performance.

Filter Housings with Cartridge | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Removes Particle Size Down To, microns | Replacement Cartridges | |||||||||||||

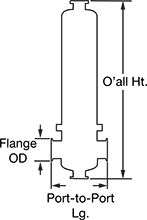

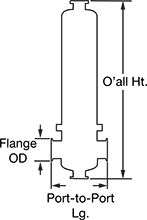

| For Tube OD | Flange OD | Steam Capacity | 98% Efficiency | 100% Efficiency | Max. Pressure, psi | Max. Temp., °F | Cartridge Useful Life | Port-to-Port Length | Overall Height | Specifications Met | Each | Each | ||

Quick Clamp Tube Vent and Drain | ||||||||||||||

316 Stainless Steel Housing and Cartridge | ||||||||||||||

| 1/2" | 0.984" | 100 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 4 23/32" | 9" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 000000000 | 0000000 | 0000000 |

| 1" | 1.984" | 400 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 14 1/2" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 000000 |

| 2" | 1.984" | 800 lbs./hr. @ 100 psi | 1 | 2 | 230 | 300 | Reusable up to 6 times | 6 3/8" | 19 3/4" | 3-A Certified 10-04, ASME BPE, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 00000000 | 00000000 | 0000000 | 00000000 |

Sanitary Metal Filter Housings

Along with a cartridge, these housings are used in liquid processing lines to filter contaminants and minimize bacteria growth in food and pharmaceutical plants, as well as other sanitary environments. Made of 316 stainless steel, they won’t corrode from frequent washdowns with harsh cleaners. With a self-draining design, rounded edges, and highly polished surfaces, they leave no space for liquids to linger or bacteria to grow. These housings connect to process lines with sanitary quick-clamp fittings that allow for fast disassembly and cleaning. An EPDM rubber gasket maintains a tight seal and resists water, detergents, chemicals, and steam. The gasket is FDA compliant for direct contact with food. Housings are 3-A certified for sanitary design standards and comply with FDA pharmaceutical equipment design standards.

Cartridges (sold separately) are pleated, creating a large surface area for trapping debris. They have one open end with an EPDM rubber O-ring and locking tabs—the O-ring creates a tight seal to ensure that liquids pass through the cartridge for filtration, while the locking tabs help align with cartridges for a secure fit. Cartridges are FDA compliant for direct contact with food.

Cartridges with a polypropylene filter are often used as pre-filters in liquid processing lines, capturing larger particles to prevent clogging.

Cartridges with a PES filter remove extremely small particles, so they’re commonly used as final filters in high-purity applications. They’re also known as absolute-rated cartridges.

For Cartridge | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Ht. | ID | End Type | No. of Cartridges Required | Max. Flow Rate, gpm | Max. Pressure, psi | Max. Temp., °F | Port-to-Port Length | Overall Height | Specifications Met | Each | |

| 1" | 1.984" | 21.9" | 2.2" | O-Ring End Caps | 1 | 15 | 150 | 300 | 9 13/16" | 32 1/4" | 3-A Certified 10-04, FDA Compliant 21 CFR 177.2600, FDA Compliant 21 CFR 211.65 | 0000000 | 000000000 |

Removes Particle Size Down To, microns | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Height | 80% Efficiency | 90% Efficiency | 98% Efficiency | 99.9% Efficiency | Max. Pressure, psi | Max. Temp., °F | Specifications Met | Each | |

Polypropylene Plastic | |||||||||

| 21.9" | 3 | 5 | 10 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 0000000 |

| 21.9" | 10 | 20 | 30 | __ | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

PES Plastic | |||||||||

| 21.9" | __ | __ | __ | 0.2 | 80 | 180 | FDA Compliant 21 CFR 177.1520, FDA Compliant 21 CFR 177.2240, FDA Compliant 21 CFR 177.2600 | 0000000 | 000000 |

Stainless Steel Quick-Clamp T-Strainers

- Max. Pressure for Beverage, Dairy, Food, Pharmaceuticals, and Water: 150 psi @ 72° F

- Temp. Range: -50° to 275° F

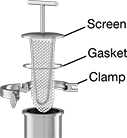

Add these inline T-strainers to your sanitary process line to trap solid particles during clean-in-place (CIP) cycles. They have quick-clamp sanitary tube connections, also known as tri-clamp connections, for use in dairy, food, and other process lines that require frequent cleaning and disassembly. As the high-pressure cleaning fluid flows through your line, the strainer's screen catches particles larger than 1/8" to prevent damage to pumps, valves, and other downstream components. And because the total open area of the screen is larger than the area of the tube itself, the screen will not restrict flow.

Strainers come with a gasket and clamp to secure the screen inside the strainer. Gaskets and clamps for connecting the strainer to your line are sold separately. A handle lets you remove the screen to clean it between runs.

Strainers | Replacement Clamps | Replacement Screens | Replacement EPDM Gaskets | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| For Tube OD | Flange OD | Lg. | Ht. | Screen Material | Screen Opening Size | Screen Lg. | Each | Each | Each | Each | ||||

316 Stainless Steel | ||||||||||||||

| 1 1/2" | 1.984" | 5 1/2" | 5 7/8" | 316 Stainless Steel | 1/8" | 3 1/2" | 0000000 | 0000000 | 00000000 | 000000 | 0000000 | 0000000 | 0000000 | 00000 |

| 2" | 2.516" | 7" | 6 7/8" | 316 Stainless Steel | 1/8" | 4 1/2" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 2 1/2" | 3.047" | 7" | 7 3/16" | 316 Stainless Steel | 1/8" | 4 3/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

| 3" | 3.579" | 7 1/2" | 7 11/16" | 316 Stainless Steel | 1/8" | 5 1/4" | 0000000 | 000000 | 00000000 | 00000 | 0000000 | 000000 | 0000000 | 0000 |

Screens for Stainless Steel Quick-Clamp T-Strainers

Use these replacement screens with our Stainless Steel Quick-Clamp T-Strainers. Designed for use in dairy, food, and other process lines that use clean-in-place (CIP) systems, they prevent damage to pumps, valves, and other downstream components. Insert the screen into the strainer, then add a gasket and clamp to seal. The screen catches particles larger than 1/8" without restricting flow.

| For Tube OD | For Flange OD | Screen Opening Size | Screen Lg. | Screen Material | For Use With | Each | |

| 1 1/2" | 1.984" | 1/8" | 3 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 0000000 |

| 2" | 2.516" | 1/8" | 4 1/2" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 2 1/2" | 3.047" | 1/8" | 4 3/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

| 3" | 3.579" | 1/8" | 5 1/4" | 316 Stainless Steel | Beverage, Dairy, Food, Pharmaceuticals, Water | 0000000 | 000000 |

Sanitary Magnetic Strainers

- For Use With: Beverage, Dairy, Food, Salt Solutions, Sodium Nitrate, Water

- Max. Pressure: 150 psi @ 225° F

- Temp. Range: -20° to 225° F

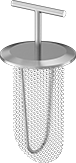

Draw metal shavings and other contaminants out of your sanitary liquid line with these strainers. As liquid swirls through the strainer cavity, magnets sealed inside capture any metal bits. Remaining impurities are separated out with gravity and trapped in a collection sump. Empty the strainers by removing the lid and scooping up the collected particles at the bottom of the enclosure. These strainers have quick-clamp connections, so they’re good for frequent deep cleans and line changes. Also known as tri-clamp fittings, they connect with a gasket, a clamp, and another quick-clamp fitting for quick removal and assembly.

These strainers are 316 stainless steel, which won’t corrode from frequent washdowns with harsh cleaners. The continuous weld seams and polished surfaces are free of pits and crevices where bacteria could grow, making them easy to sanitize. Rated for high temperatures, you can keep these strainers on your line during a heated clean-in-place (CIP) process. All strainers and their included gasket are FDA compliant, meaning they are safe for food contact.

Filters that are USDA certified meet the highest standards of sanitary design.

| Pipe Size | Max. Magnetic Pull, lbs. | Lg. | Ht. | Magnet Material | Gasket Material | Specifications Met | Each | |

316 Stainless Steel | ||||||||

|---|---|---|---|---|---|---|---|---|

| 2 | 14.25 | 9 3/4" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 000000000 |

| 2 | 14.25 | 9 3/4" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 9 3/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |

| 3 | 14.25 | 9 13/16" | 11 7/8" | Neodymium | Buna-N Rubber | FDA Compliant 21 CFR 177.2600 | 0000000 | 00000000 |