Filter by

For Testing

Concentration

pH Range

DFARS Specialty Metals

Capacity

Performance

Bottle Material

Water Test Kits

|  |

Analog | Digital |

Test Kits | Refill Chemicals | ||||||||

|---|---|---|---|---|---|---|---|---|---|

For Testing | Range | Test Type | No. of Tests | Each | Each | ||||

| Arsenic | 0.002-0.30 ppm | Analog | 5 | 000000 | 000000 | ——— | 0 | ||

| Bacteria | 1 Colony per 100 ml Water | Analog | 1 | 0000000 | 0000 | ——— | 0 | ||

| Chloride | 0-200 ppm/0-20,000 ppm | Analog | 50 | 0000000 | 00000 | 0000000 | 000000 | ||

| Dissolved Oxygen | 0-10 ppm | Analog | 50 | 0000000 | 00000 | 0000000 | 00000 | ||

| Free Chlorine, Total Chlorine | 0.2-3.0 ppm | Analog | 50 | 000000 | 000000 | 0000000 | 00000 | ||

| Hydrogen Sulfide, Sulfide | 0-5.85 ppm | Digital | 90 | 0000000 | 000000 | 0000000 | 00000 | ||

| Iron | 0-5 ppm | Digital | 50 | 0000000 | 000000 | 0000000 | 00000 | ||

| Iron | 0.5-10 ppm | Analog | 90 | 0000000 | 00000 | ——— | 0 | ||

| Lead | 0.015 ppm | Analog | 2 | 0000000 | 00000 | ——— | 0 | ||

| Molybdenum | 1-10 ppm | Analog | 100 | 0000000 | 000000 | 0000000 | 00000 | ||

| Nitrate Nitrogen | 0.25-10.0 ppm | Analog | 50 | 0000000 | 000000 | 0000000 | 00000 | ||

| Phosphate | 1.0-10.0 ppm/10-100 ppm | Analog | 50 | 0000000 | 000000 | ——— | 0 | ||

| pH | 3-10.5 pH | Analog | 100 | 000000 | 00000 | 0000000 | 00000 | ||

| Total Alkalinity | 0-200 ppm | Analog | 50 | 0000000 | 00000 | 0000000 | 00000 | ||

| Total Hardness | 0-200 ppm | Analog | 50 | 0000000 | 00000 | 0000000 | 00000 | ||

Combination Water Test Kits

Test Kits | Refill Chemicals | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Testing | Range | Test Type | No. of Tests | Each | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

367 Tests | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total Hardness Phenolphthalein Alkalinity, Total Alkalinity Chloride Dissolved Oxygen Phosphate Sulfite | 5.0 ppm to 15.0 ppm, 100 ppm to 300 ppm 100 ppm to 300 ppm, 500 ppm to 1,500 ppm 100 ppm to 300 ppm, 5,000 ppm to 15,000 ppm 1.0 ppm to 12.0 ppm 1.0 ppm to 10 ppm, 10 ppm to 100 ppm 20 ppm to 60 ppm, 50 ppm to 150 ppm | Analog Analog Analog Analog Analog Analog | 75 75 75 30 12 100 | 00000000 | 0000000 | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

340 Tests | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total Hardness Iron Total Dissolved Solids (TDS) Total Chlorine pH | 0-30 gpg 1-5 ppm 0- 9,990 ppm 0.1-2.0 ppm 5-10 pH | Analog Analog Digital Analog Analog | 120 50 50 120 | 0000000 | 000000 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

290 Tests | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total Hardness Iron Total Dissolved Solids (TDS) Hydrogen Sulfide, Sulfide | 0-30 gpg 1-5 ppm 0-9,990 ppm 0.2-5.0 ppm | Analog Analog Digital Analog | 120 50 120 | 0000000 | 000000 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

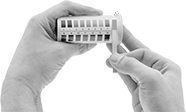

Water-Quality Test Strips

For Testing | Range | No. of Strips | Each | ||

|---|---|---|---|---|---|

| Ammonia | 0 ppm to 6 ppm | 25 | 00000000 | 000000 | |

| Chloride | 0 ppm to 500 ppm | 50 | 00000000 | 00000 | |

| Copper | 0 ppm to 3 ppm | 25 | 00000000 | 00000 | |

| Free Chlorine | 0 ppm to 800 ppm | 50 | 00000000 | 00000 | |

| Free Chlorine, Total Chlorine | 0 ppm to 10 ppm | 25 | 00000000 | 00000 | |

| Hydrogen Peroxide | 0 ppm to 90 ppm | 25 | 00000000 | 00000 | |

| Iron | 0 ppm to 5 ppm | 25 | 00000000 | 00000 | |

| Molybdenum | 0 ppm to 5 ppm | 50 | 00000000 | 00000 | |

| Nitrate, Nitrite | 0 ppm to 50 ppm 0 ppm to 10 ppm | 50 | 00000000 | 00000 | |

| Peracetic Acid | 0 ppm to 160 ppm | 50 | 00000000 | 00000 | |

| Phosphorus | 0 ppb to 2,500 ppb | 25 | 00000000 | 00000 | |

| Salinity | 0% to 150% | 50 | 00000000 | 00000 | |

| Total Alkalinity | 0 ppm to 180 ppm | 50 | 0000000 | 00000 | |

| Total Hardness | 0 ppm to 180 ppm | 50 | 00000000 | 00000 | |

| Total Hardness | 0 gpg to 58 gpg | 50 | 00000000 | 00000 | |

| pH | 0 pH to 14 pH | 100 | 00000000 | 00000 | |

| pH | 0 pH to 6 pH | 100 | 00000000 | 00000 | |

| pH | 6.5 pH to 13 pH | 100 | 00000000 | 00000 | |

| pH | 4 pH to 10 pH | 50 | 00000000 | 00000 | |

| Free Chlorine, Total Chlorine Total Alkalinity Total Hardness pH | 0 ppm to 10 ppm 0 ppm to 425 ppm 0 ppm to 240 ppm 6.2 pH to 8.4 pH | 30 | 00000000 | 00000 |

pH Testing Paper

|

pH Range, pH | pH Numeric Increments, pH | No. of Color Points | Wd. | Lg., ft. | Each | ||

|---|---|---|---|---|---|---|---|

| 0 to 13 | 1 | 14 | 1/2" | 50 | 0000000 | 000000 | |

| 1 to 6 | 1 | 6 | 1/4" | 15 | 0000000 | 0000 | |

| 1 to 11 | 1 | 11 | 1/2" | 50 | 0000000 | 00000 | |

| 3 to 5.5 | 0.5 | 6 | 1/2" | 50 | 0000000 | 00000 | |

| 3 to 9 | 1 | 7 | 1/2" | 50 | 0000000 | 00000 | |

| 6 to 8 | 0.4 | 7 | 1/2" | 50 | 0000000 | 00000 | |

| 6.5 to 13 | 0.5 | 14 | 1/4" | 15 | 000000 | 0000 | |

| 8 to 9.5 | 0.5 | 4 | 1/4" | 15 | 0000000 | 0000 | |

| 10 to 12 | 0.5 | 5 | 1/4" | 15 | 0000000 | 0000 |

Disposable Liquid Samplers

Style A | Style B | Style C |

Style C

Bottle | Needle | ||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Dia. | Ht. | Material | Cap Material | Ga. | Lg. | ID | OD | Material | Fitting Connection | Color | Autoclavable | Max. Temp., ° F | Features | Includes | Each | |||

| 45 | 1 1/2" | 4 1/4" | Polypropylene | Polypropylene | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | No | 110 | Leakproof Lid | One Tamper Seal Label | 0000000 | 00000 | ||

Cleaned and Packaged Disposable Liquid Samplers

Sterile Disposable Liquid Samplers

Disposable Thick Liquid Samplers

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Max. Viscosity, cP | Dia. | Lg. | Autoclavable | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 100 | 7/8" | 39 1/2" | No | 140 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Sterile Disposable Thick Liquid Samplers

|

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Max. Viscosity, cP | Dia. | Lg. | Autoclavable | Max. Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyethylene | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 200 | 100 | 7/8" | 39 1/2" | No | 140 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Vacuum Liquid Samplers

Bottle | Hose | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of Bottles | Cap., ml | Ht. | Width | Dp. | Material | ID | OD | Lg., ft. | Material | Wt. Material | Autoclavable | Pump Material | Max. Temp., ° F | Includes | Each | |||

| 10 | 100 | 4 1/4" | 1 3/4" | 1 3/4" | Polyethylene | 0.24" | 0.31" | 32 | Polyethylene | 304 Stainless Steel | No | Polyethylene | 140 | 20 Tamper Seal Labels, Hose Cutter, Case | 0000000 | 0000000 | ||

Large-Capacity Sterile Disposable Liquid Samplers

Bag | Hose | Needle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Ht. | Wd. | Thk., mil | ID | OD | Lg., ft. | Material | Ga. | Lg. | ID | OD | Material | Fitting Connection | Color | Max. Temp. | Specs. Met | USP Class | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PVC Bag | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 8" | 5" | 14 | 1/8" | 3/16" | 3 | PVC | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | Not Rated | ISO 10993 | VI | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2,000 | 14" | 7" | 14 | 1/8" | 3/16" | 3 | PVC | 18 | 1 1/2" | 0.033" | 0.05" | 304 Stainless Steel | Luer Lock | Clear | Not Rated | ISO 10993 | VI | 0000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Liquid Samplers for Extra-Large Tanks

Liquid Samplers

| |||

Polypropylene with Valve Operation | PTFE with Button Operation | 316 Stainless Steel with Pull Ring Operation |

Overall | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Cap., ml | Dia. | Lg. | Autoclavable | Max. Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polypropylene with Valve Operation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 140 | 1" | 19 1/2" | Yes | 140 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 280 | 1" | 39" | Yes | 140 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 500 | 1" | 39" to 78 1/2" | Yes | 140 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE with Button Operation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 250 | 1 1/4" | 39 1/2" | Yes | 140 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel with Pull Ring Operation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 50 | 1 1/4" | 18" | Yes | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 100 | 1 1/4" | 22" | Yes | — | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||