Wear-Recognition Go Plug Gauges

A black-oxide treatment on these go gauges shows wear patterns so you can tell when you need to calibrate or replace the gauge—use them to check to minimum hole diameter. They help you measure hole sizes and depths, check hole location and distance, and set micrometers. All come with a certificate of accuracy traceable to NIST that states they’ve passed a test for accuracy.

If a go gauge can enter the hole and a no-go gauge is unable to enter, the hole is within tolerance.

For technical drawings and 3-D models, click on a part number.

| Choose a Size | Increment | Gauge Tolerance | Length | Surface Smoothness (RMS), microinch | Hardness | Material | Each | |

Class ZZ | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.0110" to 0.0605" | 0.0005" | 0" to 0.0002" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 00000 |

| 0.0610" to 0.5005" | 0.0005" | 0" to 0.0002" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

| 0.5010" to 0.6255" | 0.0005" | 0" to 0.0002" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

| 0.6260" to 0.7505" | 0.0005" | 0" to 0.0002" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

Wear-Recognition No-Go Plug Gauges

The black-oxide treatment on these no-go gauges shows wear patterns so you can tell when you need to calibrate or replace the gauge—they help you check the maximum hole diameter. Use them to measure hole sizes and depths, check hole location and distance, and set micrometers. They come with a certificate of accuracy traceable to NIST that states they’ve passed a test for accuracy.

If a no-go gauge is unable to enter the hole and a go gauge can, the hole is within tolerance.

For technical drawings and 3-D models, click on a part number.

| Choose a Size | Increment | Gauge Tolerance | Length | Surface Smoothness (RMS), microinch | Hardness | Material | Each | |

Class ZZ | ||||||||

|---|---|---|---|---|---|---|---|---|

| 0.0110" to 0.0605" | 0.0005" | -0.0002" to 0" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 00000 |

| 0.0610" to 0.5005" | 0.0005" | -0.0002" to 0" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

| 0.5010" to 0.6255" | 0.0005" | -0.0002" to 0" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

| 0.6260" to 0.7505" | 0.0005" | -0.0002" to 0" | 2" | 10 | Rockwell C60 | Black-Oxide Tool Steel | 00000000 | 0000 |

Plug Gauge Sets

Keep dozens of plug gauges on hand to check a range of hole sizes. You’ll often hear them called pin gauges. Use them to measure hole size and depth with precise go/no-go tests, check hole location and distance, and set micrometers. Sets include a manufacturer's certificate of accuracy to certify diameters are within tolerance. Gauges are tool steel, so they’re strong, hard, and resist wear.

If a go gauge can enter the hole and a no-go gauge is unable to enter, the hole is within tolerance. Go gauges check the minimum hole diameter. No-go gauges check the maximum hole diameter.

Choose a class based on the level of precision you need—the smaller the tolerance, the greater the accuracy. Classes are based on ASME standard B89.1.5, which states diameter won’t vary more than the listed plug gauge tolerance. Class ZZ gauges are ideal for quick checks that don't require extreme precision.

Black-oxide tool steel gauges show wear patterns, so you know when to calibrate or replace them.

For technical drawings and 3-D models, click on a part number.

| Plug Gauge Size | Increment | No. of Pieces | Lg. | Surface Smoothness (RMS), microinch | Material | Plug Gauge Tolerance | Specifications Met | Each | |

Go Gauges | |||||||||

|---|---|---|---|---|---|---|---|---|---|

With Case | |||||||||

Class ZZ | |||||||||

| 0.0110" to 0.0600" | 0.001" | 50 | 2" | 10 | Black-Oxide Tool Steel | 0" to 0.0002" | ASME B89.1.5 | 0000000 | 000000 |

| 0.0610" to 0.2500" | 0.001" | 190 | 2" | 10 | Black-Oxide Tool Steel | 0" to 0.0002" | ASME B89.1.5 | 0000000 | 000000 |

No-Go Gauges | |||||||||

With Case | |||||||||

Class ZZ | |||||||||

| 0.0110" to 0.0600" | 0.001" | 50 | 2" | 10 | Black-Oxide Tool Steel | -0.0002" to 0" | ASME B89.1.5 | 0000000 | 00000 |

| 0.0610" to 0.2500" | 0.001" | 190 | 2" | 10 | Black-Oxide Tool Steel | -0.0002" to 0" | ASME B89.1.5 | 0000000 | 000000 |

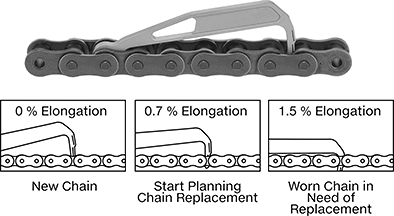

High-Accuracy Roller Chain Wear-Indicating Gauges

Precisely measure chain elongation to see if you need to replace your chain. These gauges give a more accurate reading than alternatives because they’re designed to anchor to a roller and extend across several links. A color indicator helps you quickly measure the space between rollers. If the gauge rests on top of the chain and you see green markings, your chain doesn't need to be replaced. If it slips between two rollers and you only see red markings, it’s time for a replacement.

| For Roller Chain Trade Size | Material | Each | |

For Single-, Double-, and Triple-Strand ANSI Roller Chain | |||

|---|---|---|---|

| 35 | Steel | 0000000 | 0000000 |

| 40 | Steel | 0000000 | 000000 |

| 50 | Steel | 0000000 | 000000 |

| 60 | Steel | 0000000 | 000000 |

| 80 | Steel | 0000000 | 000000 |

| 100 | Steel | 0000000 | 000000 |

| 120 | Steel | 0000000 | 000000 |

| 140 | Steel | 0000000 | 000000 |

| 160 | Steel | 0000000 | 000000 |

| 180 | Steel | 0000000 | 000000 |

| 200 | Steel | 0000000 | 00000000 |

| 240 | Steel | 0000000 | 00000000 |

For Single-, Double-, and Triple-Strand ISO Roller Chain | |||

| 06B | Steel | 0000000 | 000000 |

| 08B | Steel | 0000000 | 000000 |

| 10B | Steel | 0000000 | 000000 |

| 12B | Steel | 0000000 | 000000 |

| 16B | Steel | 0000000 | 000000 |

| 20B | Steel | 0000000 | 000000 |

| 24B | Steel | 0000000 | 000000 |

| 28B | Steel | 0000000 | 000000 |

| 32B | Steel | 0000000 | 000000 |

| No. of Gauges | For Roller Chain Trade Size | Material | Includes | Each | |

For Single-, Double-, and Triple-Strand ANSI Roller Chain | |||||

|---|---|---|---|---|---|

| 5 | 35, 40, 50, 60, 80 | Steel | Chain Indentification Tool | 0000000 | 000000000 |

For Single-, Double-, and Triple-Strand ISO Roller Chain | |||||

| 5 | 06B, 08B, 10B, 12B, 16B | Steel | Chain Indentification Tool | 0000000 | 00000000 |

ANSI Roller Chain Wear-Indicating Inserts

Place these steel inserts between two roller links. If they can be inserted past your ANSI number, the chain is worn out.

Overall | |||||

|---|---|---|---|---|---|

| For Roller Chain Trade Size | Lg. | Wd. | Material | Each | |

For Single- and Double-Strand ANSI Roller Chain | |||||

| 35, 40, 41, 50, 60, 80, 100, 35-2, 40-2, 50-2, 60-2, 80-2, 100-2 | 8 3/4" | 5/8" | Steel | 000000 | 0000000 |

| 80, 100, 120, 140, 160, 180, 200, 240, 80-2, 100-2, 120-2, 140-2, 160-2, 180-2, 200-2, 240-2 | 18" | 1 1/2" | Steel | 000000 | 000000 |

ANSI Roller Chain Wear-Indicating Rulers

Place this plastic ruler on links to measure chain wear.

Overall | |||||

|---|---|---|---|---|---|

| For Roller Chain Trade Size | Lg. | Wd. | Material | Each | |

For Single- and Double-Strand ANSI Roller Chain | |||||

| 40, 41, 50, 60, 80, 100, 120, 140, 160, 180, 200, 240, 40-2, 50-2, 60-2, 80-2, 100-2, 120-2, 140-2, 160-2, 180-2, 200-2, 240-2 | 15" | 2 5/8" | Plastic | 000000 | 00000 |

Wear Gauges for Grade 80 and Grade 100 Chain

Gauge measures the maximum allowable wear tolerances on links of Grade 80 or Grade 100 steel chain, as required by OSHA. If the gauge can be inserted over any part of the link, the chain should be taken out of service.

| For Straight-Link Chain Trade Size | For Manufacturer Model Number | Each | |

For Grade 80 and Grade 100 Chain | |||

|---|---|---|---|

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | L8, L10 | 00000000 | 000000 |

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | P8, P10, H29, KWB | 00000000 | 00000 |

For Grade 100 Chain | |||

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | C10 | 0000000 | 00000 |

| 9/32, 3/8, 1/2, 5/8, 3/4, 7/8, 1 | PW, PWA | 00000000 | 00000 |