Filter by

TIG Welding Type

TIG Industry Number

Export Control Classification Number (ECCN)

DFARS Specialty Metals

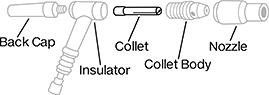

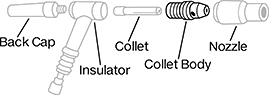

Component

TIG Torch Collets

For Torch Series No. | For Nozzle Material | For Gas Coverage | Choose an Electrode Diameter (Industry Number) | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Split TIG Collet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | Ceramic Alumina, Silicon Nitride Ceramic, Quartz Glass | Narrow | 0.020" (13N20) , 0.040" (13N21) | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20, 25 | Ceramic Alumina, Silicon Nitride Ceramic, Quartz Glass | Narrow, Wide | 0.063" (13N22) , 0.094" (13N23) , 0.125" (13N24) | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | Ceramic Alumina, Silicon Nitride Ceramic, Quartz Glass | Narrow | 0.040" (10N22) , 0.063" (10N23) , 0.094" (10N24) , 0.125" (10N25) , 0.156" (54N20) | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Wedge TIG Collet | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | Silicon Nitride Ceramic, Borosilicate Glass | Narrow | 0.063" , 0.094" , 0.125" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | Silicon Nitride Ceramic, Borosilicate Glass | Narrow | 0.063" , 0.094" , 0.125" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | Borosilicate Glass | Wide | 0.063" , 0.094" , 0.125" | 00000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

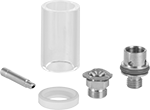

TIG Torch Accessory Kits

|

For Narrow Gas Coverage | For Wide Gas Coverage | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Torch Series No. | For Electrode Dia. | Includes | Each | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Borosilicate Glass Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.063" | Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 000000 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.094" | Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.125" | Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.063" | Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.094" | Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.125" | Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser Borosilicate Glass Nozzle | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Ceramic Alumina Nozzle | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Standard TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 0.040", 0.063" | Long Back Cap 0.040" Collet 0.063" Collet 0.040" Collet Body 0.063" Collet Body Size 4 Aluminum Oxide Ceramic Nozzle Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.040" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17 | 0.040", 0.063", 0.094" | Short Back Cap 0.040" Collet 0.063" Collet 0.094" Collet 0.040" Collet Body 0.063" Collet Body 0.094" Collet Body Size 4 Aluminum Oxide Ceramic Nozzle Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.040" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 18, 26 | 0.063", 0.094", 0.125" | Short Back Cap 0.063" Collet 0.094" Collet 0.125" Collet 0.063" Collet Body 0.094" Collet Body 0.125" Collet Body Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle Size 8 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.125" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 20 | 0.063", 0.094", 0.125" | Long Back Cap 0.063" Collet 0.094" Collet 0.125" Collet 0.063" Collet Body 0.094" Collet Body 0.125" Collet Body Size 5 Aluminum Oxide Ceramic Nozzle Size 6 Aluminum Oxide Ceramic Nozzle Size 7 Aluminum Oxide Ceramic Nozzle 7" Long 2% Ceriated Tungsten Electrode with 0.063" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.094" Diameter 7" Long 2% Ceriated Tungsten Electrode with 0.125" Diameter | 0000000 | 00000 | ——— | 0 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gas-Saving TIG Welding | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.063" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.094" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9, 20 | 0.125" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.063" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.063" Collet 0.063" Collet Body 0.063" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.094" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.094" Collet 0.094" Collet Body 0.094" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 17, 18, 26 | 0.125" | Aluminum Oxide Ceramic Nozzle Gas Lens Insulator 0.125" Collet 0.125" Collet Body 0.125" Gas Diffuser | 0000000 | 00000 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

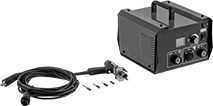

Stud Welders

Welders

Input | Overall | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Stud Weld Rate | Voltage, V AC | Freq., Hz | Current, amp | Output Voltage Range, V DC | Ht. | Wd. | Dp. | Cord Lg., ft. | Includes | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Three Blade | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 per min. @ 200V DC | 120 | 60 | 10 | 70 to 200 | 13" | 12" | 9" | 6 | Control Unit Welding Gun with 21-ft. Cable 4 Stop Pins for Setting Threaded Studs and Pins in Collet 15-ft. Ground Cable with 2 Ground Clamps | 0000000 | 000000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Threaded Studs

Copper-Plated Steel | 18-8 Stainless Steel | Aluminum | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Thread Size | For Collet Thread Size | Head Dia. | Lg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||

| 4-40 | 4-40 | 3/16" | 1/2" | 100 | 0000000 | 000000 | — | ——— | 0 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 3/8" | 100 | 00000000 | 00000 | 100 | 00000000 | 000000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 1/2" | 100 | 0000000 | 0000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 3/4" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 6-32 | 6-32 | 7/32" | 1 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 3/8" | 100 | 00000000 | 00000 | — | ——— | 0 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 1/2" | 100 | 0000000 | 0000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 5/8" | 100 | 00000000 | 00000 | — | ——— | 0 | — | ——— | 0 | ||

| 8-32 | 8-32 | 1/4" | 3/4" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-24 | 10-24 | 1/4" | 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-24 | 10-24 | 1/4" | 3/4" | — | ——— | 0 | — | ——— | 0 | 100 | 00000000 | 000000 | ||

| 10-24 | 10-24 | 1/4" | 1" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 3/8" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 1/2" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 10-32 | 10-32 | 1/4" | 3/4" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1/2" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | 100 | 00000000 | 00000 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 5/8" | — | ——— | 0 | 100 | 00000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 3/4" | 100 | 00000000 | 00000 | 100 | 0000000 | 00000 | — | ——— | 0 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1" | 100 | 0000000 | 00000 | 100 | 0000000 | 00000 | 100 | 00000000 | 00000 | ||

| 1/4"-20 | 1/4"-20 | 5/16" | 1 1/2" | — | ——— | 0 | 100 | 00000000 | 000000 | — | ——— | 0 | ||

TIG Torch Collet Bodies

For Ceramic Alumina and Silicon Nitride Ceramic Nozzles

TIG Torch Collet Bodies | TIG Torch Adapter Rings for Quartz Glass Nozzles | ||||||

|---|---|---|---|---|---|---|---|

For Narrow Gas Coverage | |||||||

For Torch Series No. | Choose an Electrode Diameter (Industry Number) | Each | Nozzle Connection | Each | |||

| 9, 20, 25 | 0.020" (13N25) , 0.040" (13N26) , 0.063" (13N27) , 0.094" (13N28) , 0.125" (13N29) | 00000000 | 00000 | Threaded × Push On | 000000000 | 00000 | |

| 17, 18, 26 | 0.040" (10N30) , 0.063" (10N31) , 0.094" (10N32) , 0.125" (10N28) , 0.156" (406488) | 00000000 | 0000 | Threaded × Push On | 000000000 | 0000 | |