Multicheck Weld Inspection Gauges

Check bevel angles, excess weld metal (capping size), length of a corner-weld leg, throat length, and depth of undercut.

Excess Weld Metal (Capping Size) | Corner-Weld Leg Lg. | Throat Lg. | Dp. of Undercut | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Bevel Angle Measured | Max. Size Measured | Graduation Marks | Max. Lg. Measured | Graduation Marks | Max. Lg. Measured | Graduation Marks | Max. Size Measured | Graduation Marks | Material | Includes | Each | |

MIG, TIG, Stick, Oxyacetylene Welding Process | ||||||||||||

| 0°-60° | 1", 25 mm | 1/16", 1 mm | 1", 25mm | 1/16", 1 mm | 3/4", 20mm | 1/16", 1 mm | 3/16", 5 mm | 1/16", 1 mm | Stainless Steel | Vinyl Carrying Case | 0000000 | 0000000 |

Weld Alignment Inspection Gauges

Measure internal misalignment of pipe ID, pipe wall thickness after tack welding, and go/no-go fit-up gap.

Internal Misalignment of Pipe ID | Pipe Wall Thick. After Tack Welding | ||||||

|---|---|---|---|---|---|---|---|

| Max. Size Measured | Graduation Marks | Max. Thick. Measured | Graduation Marks | Go/No-Go Fit-Up Gap Size Measured Range | Material | Each | |

MIG, TIG, Stick, Oxyacetylene Welding Process | |||||||

| 1/16", 30 mm | 1/32", 1 mm | 1 3/4", 45mm | 1/16", 1 mm | 1/16"-3/32" | Stainless Steel | 0000000 | 0000000 |

Corner Weld Inspection Gauges

Also known as a fillet gauge, this gauge measures concave and convex corner weld dimensions.

| Radius Measured | Metric Radius Measured, mm | Measures | Material | Includes | Each | |

MIG, TIG, Stick, Oxyacetylene Welding Process | ||||||

|---|---|---|---|---|---|---|

| 1/8", 3/16", 1/4", 5/16", 3/8", 7/16", 1/2", 5/8", 3/4", 7/8", 1" | 3, 5, 6, 8, 10, 11, 13, 16, 19, 22, 25 | Concave Corners, Convex Corners | Steel | Vinyl Carrying Case | 0000000 | 000000 |

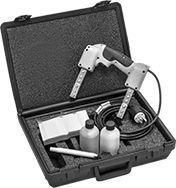

Plug-In Magnetic Particle Flaw-Detection Kits

Find faulty seams, welding defects, and other surface-level flaws in ferrous materials. These kits come with everything you need to start inspecting parts. Apply the powder to the surface you want to inspect. Then plug in the yoke and it creates a magnetic field that draws the powder to the imperfection, making it easy to spot. Built for rugged environments, the yoke has a sealed design that stands up to chemicals and other harsh conditions. It’s also half the weight of a standard yoke and fits comfortably in your hand, so there’s less fatigue if you use it for extended periods of time.

| For Use On | Includes | Plug Type | Voltage | Specifications Met | Each | |

| Cast Iron, Stainless Steel, Steel | One 1-lb. Bottle of Gray Powder, One 1-lb. Bottle of Red Powder | Three Prong | 120V AC | ASTM E1444, MIL-STD-2132, MIL-STD-271 | 000000 | 0000000 |

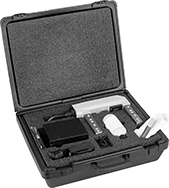

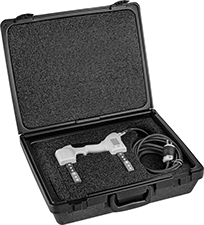

Battery-Powered Magnetic Particle Flaw-Detection Kits

Check for defects slightly beneath the surface of ferrous materials that you wouldn’t otherwise see. The yoke in these kits is powered by a battery, so it uses direct current to create a strong magnetic field that reaches just below the surface of your part. When you apply the powder, the powder will move towards any flaws, helping you identify tears, cracks, and other imperfections.

Ideal for fieldwork, these kits come with everything you need for on-the-go inspections. The yoke lasts up to eight hours on a single battery charge. Built for rugged environments, it has a sealed design that stands up to chemicals and other harsh conditions.

| For Use On | Includes | Battery Voltage | Batteries Included | Battery Charger Included | Specifications Met | Each | |

| Cobalt, Iron, Nickel, Stainless Steel, Steel | One 1-lb. Bottle of Gray Powder | 6V DC | Yes | Yes | ASTM E1444 | 0000000 | 000000000 |

Plug-In Yokes for Magnetic-Particle Flaw Detection

Find welding defects and other flaws in magnetic materials. These yokes create a magnetic field that draws magnetic powder (not included) to imperfections, making them easy to spot. All operate on AC power, which creates a small magnetic field ideal for detecting flaws along the surface of materials. Powered by standard electrical outlets, these yokes have a reliable and consistent power source.

6-lb. yokes are lightweight and fit comfortably in your hand to reduce fatigue over extended use. Attach an LED light to your yoke to brightly illuminate inspection areas. They’re powered by the yoke’s magnetic field, so they don’t require batteries.

Yokes with an AC/DC switch can also operate on DC power. DC power generates a deeper magnetic field than AC power to find defects underneath surfaces, such as internal tears and cracks.

Calibrate your yoke before each use with a test weight to ensure accurate test results.

Yokes | Test Weights | LED Light Attachments | Replacement Cords | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Voltage | Features | For Use On | Power Source | Cord Lg. | Ht. | Lg. | Weight, lbs. | Specifications Met | Each | Each | Each | Each | ||||

| 120V AC | __ | Cobalt, Iron, Nickel, Stainless Steel, Steel | Electric | 12 ft. | 7 1/2" | 12" | 6 | ASTM E1444 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 | 0000000 |

| 120V AC | AC/DC Switch | Cobalt, Iron, Nickel, Stainless Steel, Steel | Electric | 12 ft. | 7 1/2" | 12" | 8 | ASTM E1444 | 0000000 | 00000000 | 0000000 | 000000 | 000000 | 00 | 000000 | 00 |

Natural Light Flaw-Detection Kits

Use colored dye to reveal cracks and surface flaws in most nonporous material. Flaws become visible under natural light and appear as a bright red color. Commonly used for weld inspecting.

| For Use On | Includes | Specifications Met | Each | |

| Carbide, Cast Iron, Ceramic, Stainless Steel, Steel | Four 16-oz. Aerosol Cans of Cleaner, Two 16-oz. Aerosol Cans of Developer, Two 16-oz. Aerosol Cans of Red Dye | ASTM E1417, MIL-STD-2132, MIL-STD-271, SAE AMS2644 | 000000 | 0000000 |

UV Light Flaw-Detection Kits

More sensitive than natural light kits, these kits use UV light with colored dye to detect cracks, seams, and pores on machined surfaces.

Light | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| For Use On | Includes | Bulb Type | Wattage | Voltage | Electrical Connection Type | Plug Type | Cord Length, ft. | Specifications Met | Each | |

| Carbide, Cast Iron, Ceramic, Stainless Steel, Steel | One 16-oz Aerosol Can of Fluorescent Green Dye, One 16-oz. Can of Developer, Two 16-oz. Aerosol Cans of Cleaner, UV Light | Ultraviolet | 5W | 120V AC | Plug In | Three Prong | 9 | ASTM E1417, MIL-STD-2132, MIL-STD-271, SAE AMS2644 | 0000000 | 000000000 |