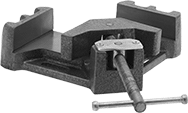

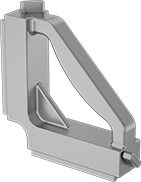

Heavy Duty Corner Clamps

With five times the capacity of standard corner clamps, these secure two workpieces at a 90° angle. They have a pivoting clamping surface to hold materials of unequal thicknesses simultaneously. The screw is copper plated to resist weld spatter.

For technical drawings and 3-D models, click on a part number.

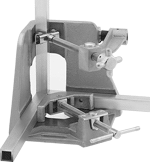

Three-Axis Corner Clamps

Clamp up to three workpieces at 90° angles. Press a button to move the threaded holding screws in or out. The third axis clamping arm swings out of the way for material removal. The screws are copper plated to resist weld spatter.

For technical drawings and 3-D models, click on a part number.

Opening | Fixed Clamping Surface | Mounting Slots | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Max. | Min. | Holding Capacity, lbs. | Ht. | Material | Number of | Lg. | Wd. | Mounting Fasteners Included | Each | |

| 3 3/4" | 0" | 550 | 1 3/8" | Iron | 2 | 1 1/2" | 7/16" | No | 0000000 | 0000000 |

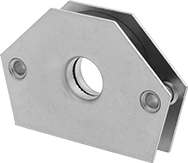

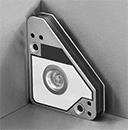

Easy On/Off Magnetic Clamps

160 lbs. Max.

Magnetic Pull

Switch the magnets on these clamps on and off for easy placement and removal of your workpiece.

Clamps with two on/off switches have magnets on opposite sides that can be turned on and off independently, letting you adjust one workpiece while the other remains clamped in place. They’re commonly used to weld two pieces of metal together. These clamps also have two always-on magnets for holding and aligning additional workpieces.

Overall | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Magnetic Pull, lbs. | Holding Angle | Lg. | Wd. | Ht. | Body Material | Features | Each | |

| 65 | 45°, 90° | 4 3/8" | 1" | 3 3/4" | Steel | __ | 0000000 | 000000 |

| 75 | 45°, 90° | 6" | 1 1/4" | 5 1/8" | Steel | __ | 0000000 | 00000 |

| 80 | 45°, 75°, 90°, 105°, 135° | 3 1/2" | 1 15/16" | 3 1/2" | Steel | __ | 0000000 | 000000 |

| 90 | 45°, 90° | 4 3/8" | 1 1/8" | 3 3/4" | Steel | __ | 0000000 | 00000 |

| 150 | 90° | 1 1/2" | 1 1/2" | 2 3/4" | Steel | __ | 0000000 | 00000 |

| 160 | 45°, 90° | 6" | 1 3/8" | 5 1/8" | Steel | __ | 0000000 | 00000 |

| 265 | 90° | 7 3/4" | 1 15/16" | 7 3/4" | Steel | Two On/Off Switches | 00000000 | 000000 |

| 450 | 90° | 3" | 2 1/2" | 4 5/8" | Steel | __ | 0000000 | 000000 |

| 1,000 | 90° | 4 1/4" | 4" | 4 3/4" | Steel | __ | 0000000 | 000000 |

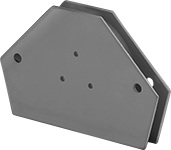

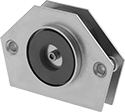

Magnetic Clamps

Hold magnetic workpieces in place with these clamps.

100- and 325-lbs. maximum pull clamps have a handle for extra leverage to remove the clamp from a surface.

Copper-plated clamps won’t scratch steel surfaces. The plating prevents weld spatter from sticking to the clamp, so sharp spatter won’t cut the user or their workpiece.

Overall | ||||||

|---|---|---|---|---|---|---|

| Max. Magnetic Pull, lbs. | Holding Angle | Lg. | Wd. | Ht. | Each | |

Steel | ||||||

| 22 | 30°, 45°, 60°, 75°, 90° | 4" | 1/2" | 2 1/2" | 0000000 | 000000 |

| 55 | 30°, 45°, 60°, 75°, 90° | 4 3/8" | 3/4" | 3" | 0000000 | 0000 |

| 100 | 45°, 90°, 135° | 8 7/8" | 1 5/8" | 8 7/8" | 0000000 | 000000 |

| 110 | 30°, 45°, 60°, 75°, 90° | 4 3/8" | 1 9/16" | 3" | 0000000 | 00000 |

| 112 | 45°, 90°, 135° | 3 3/4" | 3/4" | 4 3/8" | 0000000 | 00000 |

| 325 | 45°, 90° | 8" | 1 1/2" | 8" | 0000000 | 000000 |

Copper-Plated Steel | ||||||

| 60 | 30°, 45°, 60°, 90° | 3 3/4" | 3/4" | 3 3/4" | 00000000 | 00000 |

| 60 | 45°, 90° | 3 3/4" | 3/4" | 3 3/4" | 00000000 | 00000 |

| 75 | 45°, 90° | 3 3/4" | 3/4" | 4 3/8" | 00000000 | 00000 |

Adjustable-Angle Magnetic Clamps

Two clamps connected by a pivoting arm hold workpieces at nearly any angle.

For technical drawings and 3-D models, click on a part number.

Overall | ||||||

|---|---|---|---|---|---|---|

| Max. Magnetic Pull, lbs. | Holding Angles | Lg. | Wd. | Ht. | Each | |

| 120 | 15°-180° | 7 5/8" | 3/4" | 3 3/4" | 0000000 | 000000 |

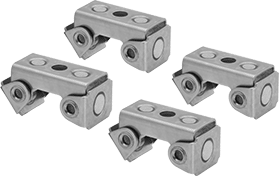

Miniature Adjustable-Angle Magnetic Clamps

Sized for small parts and tight spaces, these clamps have a pivoting pad at each end to hold workpieces at any angle up to 180°.

For technical drawings and 3-D models, click on a part number.

| Holding Angles | Number of Pieces | Includes | Each | |

| 0°-180° | 4 | Two 2 1/4" Lg. × 1" Wd. Clamps with 14 lbs. Max. Magnetic Pull Two 2 1/2" Lg. × 1 1/2" Wd. Clamps with 18 lbs. Max. Magnetic Pull | 0000000 | 000000 |

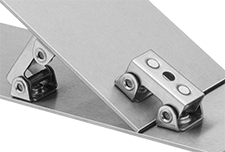

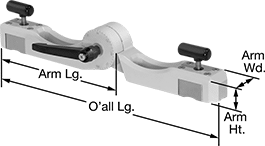

Easy On/Off Adjustable-Angle Magnetic Clamps

Each arm has a handle for turning the magnets on and off. Adjust these clamps to hold at any angle from 28° to 270° and lock the arms in place at the joint.

For technical drawings and 3-D models, click on a part number.

Arm | ||||||||

|---|---|---|---|---|---|---|---|---|

| Max. Magnetic Pull, lbs. | Holding Angles | Lg. | Wd. | Ht. | Overall Lg. | Features | Each | |

| 200 | 28°-270° | 9 1/4" | 1 11/16" | 1 1/2" | 15 3/4" | Magnet On/Off Knobs | 0000000 | 0000000 |

Three-Axis Magnetic Clamps

Hold and align up to three workpieces at 90° angles.

For technical drawings and 3-D models, click on a part number.

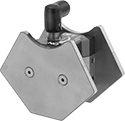

Outside-Clamping Magnetic Clamps

Clamp workpieces from the outside at a 90° angle, leaving the inside free for welding or fabrication. You can also clamp on the inside at 45° and 90°.

For technical drawings and 3-D models, click on a part number.

Overall | |||||||

|---|---|---|---|---|---|---|---|

| Max. Magnetic Pull, lbs. | Outside Holding Angle | Inside Holding Angle | Lg. | Wd. | Ht. | Each | |

| 40 | 90° | 45°, 90° | 3 7/8" | 11/16" | 3 7/8" | 0000000 | 000000 |

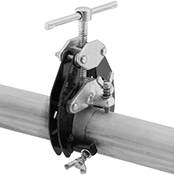

Heavy Duty Chain Clamps for Pipe Joining and Welding

The open clamp design permits welding around almost the entire pipe circumference. Secure components with chains and tighten the handles.

Aluminum clamps are lighter in weight than iron clamps. Iron clamps are more durable than aluminum.

Straight clamps are for use with two lengths of straight pipe and with reducers. Flange clamp is for flanges and straight pipe. Adjustable clamp is for use with straight pipe, elbows, tees, reducers, and risers. It pivots on a hinge to hold components at any angle from 90° to 180°.

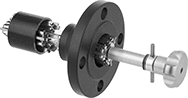

Pipe Joining and Welding Clamps

Hold pipe and fittings together for tack welding. These clamps can be used to join or weld two pipes of similar or different diameters, or they can be used to join a pipe to a flange. With a rugged build, they’re designed for use with heavy pipe.

External clamps work well when you can’t access the inside of your pipe. However, you may need to rotate them during welding to move them out of the way.

Internal clamps don’t obstruct joining or welding, making the process faster and simpler. One side of these two-part clamps expands with a knob while the other expands with a hand bar, so you can set them at different diameters to join pipe and flanges of varying sizes.

Clamps with thumb screws hold fittings or flanges at three separate points—adjust them manually to center the two pieces being joined.

Self-centering clamps consist of two clamps that share a center line even as you attach each to a different piece of pipe, so the pipes stay aligned with no manual adjustment needed.

For Pipe | ||||

|---|---|---|---|---|

| OD | Size | Body Material | Each | |

External Clamp—Thumb Screws | ||||

| 1"-2 1/2" | 3/4-2 | Steel | 0000000 | 0000000 |

| 2"-6" | 2-5 | Steel | 0000000 | 000000 |

| 5"-12" | 5-10 | Steel | 0000000 | 000000 |

External Clamp—Self-Centering | ||||

| 1/8"-3" | 1/8-2 1/2 | Stainless Steel | 0000000 | 000000 |

| 1 1/2"-5" | 1 1/4-4 | Stainless Steel | 0000000 | 000000 |

Internal Clamp—Self-Centering | ||||

| 2"-6" | 2-5 | Stainless Steel | 0000000 | 000000 |

| 4"-8" | 3 1/2-7 | Stainless Steel | 0000000 | 000000 |

| 6"-14" | 6-14 | Stainless Steel | 0000000 | 000000 |

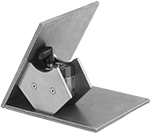

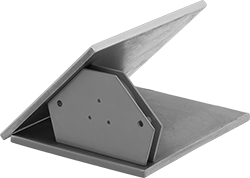

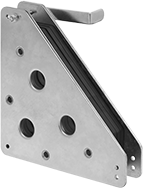

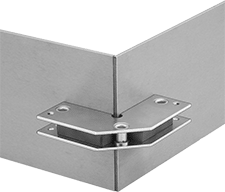

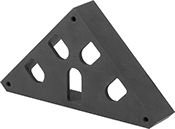

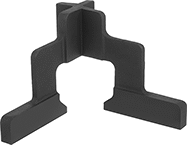

Welding Squares

Position your workpieces at the correct angle prior to welding. These squares have an extra-wide head, so you can clamp them in place.

2-axes squares set workpieces at a 45° or 90° angle. All have leveling tabs to ensure workpieces are aligned with one another. Those with joint access cutouts make it easier to reach joints, such as when welding and gluing.

3-axes squares set workpieces at a 90° angle along 3 axes at the same time.

Aluminum squares are lightweight and corrosion resistant. Cast iron squares are scratch- and dent-resistant for durability. However, they are more susceptible to corrosion than aluminum.

For technical drawings and 3-D models, click on a part number.

Overall | Aluminum | Cast Iron | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Holding Angle | Lg. | Wd. | Ht. | Flange Thick. | Includes | Each | Each | ||

2 Axes | |||||||||

| 45°, 90° | 4" | 4" | 1 1/2" | 1/4" | Leveling Tabs | 0000000 | 000000 | 0000000 | 000000 |

| 45°, 90° | 6" | 6" | 1 1/2" | 1/4" | Leveling Tabs | 0000000 | 00000 | 0000000 | 00000 |

| 45°, 90° | 12" | 12" | 3" | 1/4" | Leveling Tabs | 0000000 | 000000 | 0000000 | 000000 |

2 Axes with Joint Access Cutouts | |||||||||

| 45°, 90° | 4" | 4" | 1 1/2" | 1/4" | Leveling Tabs | 0000000 | 00000 | 0000000 | 00000 |

| 45°, 90° | 6" | 6" | 1 1/2" | 1/4" | Leveling Tabs | 0000000 | 00000 | 0000000 | 00000 |

| 45°, 90° | 12" | 12" | 3" | 3/8" | Leveling Tabs | 0000000 | 000000 | 0000000 | 000000 |

3 Axes | |||||||||

| 90° | 10 1/2" | 10 1/2" | 8" | 1" | __ | 000000 | 00 | 00000000 | 000000 |