Filter by

Hole Shape

Handle Length

Hub Projection

Grip Material

Projection

Grip Height

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Finish

Grip Finish

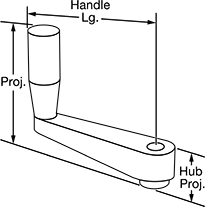

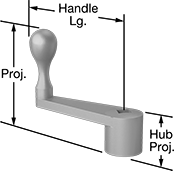

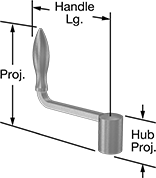

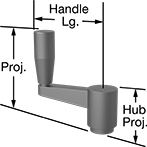

Unthreaded Through-Hole-Mount Crank Handles

|  |  |  |

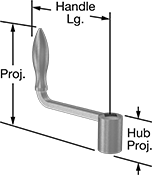

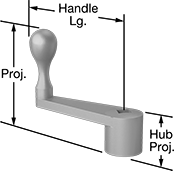

Round Hole Style 1 | Round Hole Style 2 | Round Hole Style 3 | Round Hole Style 4 |

|  |  |  |

Round Hole Style 5 | Round Hole Style 6 | Round Hole Style 7 | Round Hole Style 8 |

|  | ||

Square Hole Style 9 | Square Hole Style 10 |

Adjust machinery components with more leverage and less effort than hand wheels. The through hole in the hub attaches anywhere along the length of shafts. To mount them on unthreaded rods, drill a hole in the side of the hub and secure with a set screw; for threaded rods, tap matching threads inside the hub.

Round Hole

|  |  |  |

Style 1 | Style 2 | Style 3 | Style 4 |

|  |  |  |

Style 5 | Style 6 | Style 7 | Style 8 |

|

Folding Grip—Handles with a folding grip have a grip that folds out of the way when not in use.

Indexing Grip—Handles with a indexing grip have a pin that fits into indexed holes on equipment such as milling machines and rotary tables.

Recessed-Folding Grip—Those with a recessed folding grip have a grip that folds into the handle to stay fully out of the way.

Revolving Grip—Handles with a revolving grip let you turn continuously without having to adjust your grasp while also reducing strain on your arm.

Stationary Grip—Handles with a stationary grip are best when you need to apply high force because the grip won’t rotate or slip.

302 Stainless Steel—Stainless steel handles have excellent corrosion resistance, making them the best choice for harsh environments. They also have good chemical resistance.

Aluminum—Aluminum handles have mild corrosion resistance, are lightweight, and are nonmagnetic.

Iron—Iron handles resist damage from impact.

Nylon—Nylon handles are a lightweight alternative to metal. They resist oil, grease, and solvents.

Zinc—Zinc handles have good corrosion resistance.

Set Screw Starting Hole—Handles with a set screw starting hole have a starting hole in the hub that acts as a guide for drilling a larger hole.

Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Handle Lg. | Projection | Hub Projection | Hole Dia. | Ht. | Material | Color | Temperature Range | Features | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip with Offset Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 100 mm | 128 mm | 28 mm | 10 mm | 80 mm | Zinc-Plated Steel | — | — | — | 6544N19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 125 mm | 141 mm | 34 mm | 10 mm | 86 mm | Zinc-Plated Steel | — | — | — | 6544N2 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 160 mm | 162 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 6544N21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 200 mm | 196 mm | 44 mm | 17 mm | 118 mm | Zinc-Plated Steel | — | — | — | 6544N22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 315 mm | 248 mm | 54 mm | 20 mm | 143 mm | Zinc-Plated Steel | — | — | — | 6544N24 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 80 mm | 92 mm | 24 mm | 8 mm | 74 mm | Zinc-Plated Steel | — | — | — | 6544N31 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

302 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 3 5/16" | 3 3/8" | 3/4" | 1/2" | 3" | Stainless Steel | — | — | 1/8" Diameter Set Screw Starting Hole | 6336K4 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 4 7/8" | 3 15/16" | 7/8" | 5/8" | 3 1/2" | Stainless Steel | — | — | 3/16" Diameter Set Screw Starting Hole | 6336K7 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Offset Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 80 mm | 112 mm | 24 mm | 8 mm | 74 mm | Zinc-Plated Steel | — | — | — | 6544N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 125 mm | 141 mm | 34 mm | 10 mm | 86 mm | Zinc-Plated Steel | — | — | — | 6544N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 160 mm | 162 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 6544N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 | 315 mm | 248 mm | 54 mm | 20 mm | 143 mm | Zinc-Plated Steel | — | — | — | 6544N17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 100 mm | 101 mm | 28 mm | 10 mm | 80 mm | Zinc-Plated Steel | — | — | — | 6544N26 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 125 mm | 116 mm | 34 mm | 10 mm | 90 mm | Zinc-Plated Steel | — | — | — | 6544N27 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 160 mm | 126 mm | 38 mm | 14 mm | 97 mm | Zinc-Plated Steel | — | — | — | 6544N28 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 | 250 mm | 163 mm | 48 mm | 17 mm | 127 mm | Zinc-Plated Steel | — | — | — | 6544N3 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Painted Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 1/2" | 1 21/32" | 11/16" | 5/16" | 1 5/16" | Phenolic | Black | 0° F to 350° F | — | 6473K61 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 7/8" | 2 1/8" | 13/16" | 3/8" | 1 11/16" | Phenolic | Black | 0° F to 350° F | — | 6473K62 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 1/2" | 3" | 15/16" | 3/8" | 2 1/2" | Phenolic | Black | 0° F to 210° F | — | 6473K76 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 3/8" | 3 3/4" | 1 1/8" | 1/2" | 3 1/8" | Phenolic | Black | 0° F to 210° F | — | 6473K77 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 4 19/32" | 1 5/16" | 5/8" | 3 25/32" | Phenolic | Black | 0° F to 210° F | — | 6473K78 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 4 3/4" | 1 1/2" | 3/4" | 3 29/32" | Phenolic | Black | 0° F to 210° F | — | 6473K55 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 5/32" | 3 17/32" | 1 7/16" | 3/8" | 2 9/16" | Phenolic | Black | Not Rated to 230° F | — | 6546N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 3 15/16" | 4 11/32" | 1 9/16" | 1/2" | 3 9/32" | Phenolic | Black | Not Rated to 230° F | — | 6546N12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 5 1/8" | 5 23/32" | 1 15/16" | 5/8" | 4 1/16" | Phenolic | Black | Not Rated to 230° F | — | 6546N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 6 5/16" | 5 29/32" | 2 3/16" | 3/4" | 4 1/8" | Phenolic | Black | Not Rated to 230° F | — | 6546N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 80 mm | 86 mm | 36 mm | 10 mm | 65 mm | Phenolic | Black | Not Rated to 230° F | — | 6546N15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 100 mm | 106 mm | 40 mm | 12 mm | 84 mm | Phenolic | Black | Not Rated to 230° F | — | 6546N16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 | 130 mm | 135 mm | 49 mm | 14 mm | 109 mm | Phenolic | Black | Not Rated to 230° F | — | 6546N17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Zinc | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 1 31/32" | 1 29/32" | 11/16" | 3/8" | 1 1/2" | Polypropylene | Black | Not Rated to 175° F | — | 6547N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 2 17/32" | 2 9/16" | 13/16" | 1/2" | 2 1/8" | Polypropylene | Black | Not Rated to 175° F | — | 6547N12 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/32" | 3 5/32" | 15/16" | 1/2" | 2 5/8" | Polypropylene | Black | Not Rated to 175° F | — | 6547N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 3 5/16" | 3 15/16" | 1 1/8" | 1/2" | 3 1/4" | Polypropylene | Black | Not Rated to 175° F | — | 6547N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 50 mm | 49 mm | 18 mm | 8 mm | 39 mm | Polypropylene | Black | Not Rated to 175° F | — | 6547N15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 64 mm | 66 mm | 20 mm | 10 mm | 55 mm | Polypropylene | Black | Not Rated to 175° F | — | 6547N16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 80 mm | 81 mm | 24 mm | 10 mm | 67 mm | Polypropylene | Black | Not Rated to 175° F | — | 6547N17 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 100 mm | 100 mm | 28 mm | 12 mm | 83 mm | Polypropylene | Black | Not Rated to 175° F | — | 6547N18 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 1/8" | 2 5/8" | 7/8" | 1/2" | 1 3/4" | Phenolic | Black | Not Rated to 230° F | — | 6089K21 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 3 15/16" | 3 3/16" | 1" | 1/2" | 2 1/2" | Phenolic | Black | Not Rated to 230° F | — | 6545N11 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 4 15/16" | 3 7/8" | 1 1/8" | 5/8" | 2 13/16" | Phenolic | Black | Not Rated to 230° F | — | 6089K22 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 6 5/16" | 4 1/16" | 1 1/4" | 3/4" | 3 5/32" | Phenolic | Black | Not Rated to 230° F | — | 6545N12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 80 mm | 67 mm | 22 mm | 10 mm | 52 mm | Phenolic | Black | Not Rated to 230° F | — | 6545N13 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 100 mm | 81 mm | 26 mm | 12 mm | 63 mm | Phenolic | Black | Not Rated to 230° F | — | 6545N14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 | 125 mm | 99 mm | 28 mm | 14 mm | 80 mm | Phenolic | Black | Not Rated to 230° F | — | 6545N15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 4 1/4" | 5" | 1 1/8" | 1/2" | 3 23/32" | Phenolic | Black | 0° F to 210° F | — | 6473K91 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 5 1/2" | 6 9/32" | 1 5/16" | 5/8" | 4 17/32" | Phenolic | Black | 0° F to 210° F | — | 6473K92 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 | 6 7/8" | 6 13/32" | 1 1/2" | 3/4" | 4 21/32" | Phenolic | Black | 0° F to 210° F | — | 6473K56 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Indexing Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 75 mm | 90 mm | 24 mm | 16 mm | 90 mm | Black-Oxide Steel | — | — | — | 6544N41 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 110 mm | 90 mm | 30 mm | 20 mm | 90 mm | Black-Oxide Steel | — | — | — | 6544N43 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7 | 165 mm | 90 mm | 36 mm | 24 mm | 90 mm | Black-Oxide Steel | — | — | — | 6544N45 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Recessed-Folding Grip with Straight Arm | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Aluminum | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 5/32" | 2 11/16" | 1" | 1/2" | 2 17/32" | Nylon | Black | Not Rated to 190° F | — | 6473K31 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 3 15/16" | 3 7/16" | 1 3/16" | 1/2" | 3 3/16" | Nylon | Black | Not Rated to 190° F | — | 6473K32 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 4 29/32" | 4 15/32" | 1 7/16" | 5/8" | 4 1/32" | Nylon | Black | Not Rated to 190° F | — | 6473K33 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 80 mm | 69 mm | 26 mm | 10 mm | 65 mm | Nylon | Black | Not Rated to 190° F | — | 6473K34 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 125 mm | 113 mm | 37 mm | 14 mm | 103 mm | Nylon | Black | Not Rated to 190° F | — | 6473K36 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

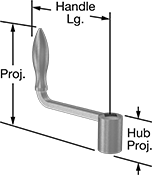

Square Hole

|  |

Style 9 | Style 10 |

Square long shafts can pass through these handles for mounting versatility. Drill a hole in the side of the hub to secure with a set screw. These crank handles provide leverage to maximize force for turning and tightening. They are often used on cross-slide tables.

Stationary Grip—Handles with a stationary grip are best when you need to apply high force because the grip won’t rotate or slip.

Revolving Grip—Handles with a revolving grip let you turn continuously without having to adjust your grasp while also reducing strain on your arm.

Iron—Iron handles are powder coated for added durability.

Steel—Steel handles are stronger than iron.

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Style | Handle Lg. | Projection | Dia. | Projection | Hole Wd. | Ht. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 2 5/8" | 3 5/8" | 1" | 1 1/4" | 1/2" | 2 7/32" | Steel | 6040K12 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 4" | 4 5/16" | 1 1/16" | 1 5/16" | 1/2" | 2 1/2" | Steel | 6040K14 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 4 1/2" | 4 1/2" | 1 1/4" | 1 3/8" | 9/16" | 2 11/16" | Steel | 6040K15 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 5 1/2" | 4 15/16" | 1 1/4" | 1 13/16" | 5/8" | 2 7/8" | Steel | 6040K16 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 6 1/2" | 5 1/8" | 1 1/4" | 1 15/16" | 11/16" | 2 15/16" | Steel | 6040K17 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 8" | 5 7/16" | 1 3/8" | 2 1/16" | 3/4" | 2 7/8" | Steel | 6040K18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 9" | 6 1/16" | 1 9/16" | 2 7/16" | 7/8" | 3 3/16" | Steel | 6040K19 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9 | 11" | 7" | 1 3/4" | 3" | 1" | 3 1/2" | Steel | 6040K22 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gray Powder-Coated Iron | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 4 7/16" | 3 7/8" | — | 1 3/8" | 9/16" | 2 7/8" | Chrome-Plated Steel | 6089K15 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 5 9/16" | 5 3/8" | — | 1 13/16" | 5/8" | 3 31/32" | Chrome-Plated Steel | 6089K16 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10 | 7 5/8" | 5 15/16" | — | 2 1/16" | 3/4" | 4 7/32" | Chrome-Plated Steel | 6089K18 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

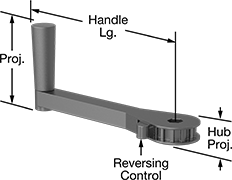

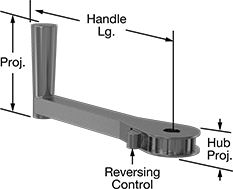

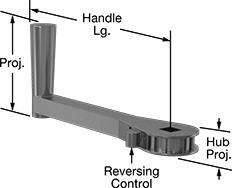

Ratcheting Unthreaded Through-Hole-Mount Crank Handles

|  |

Hex Hole | Round Hole with Keyway |

| |

Square Hole |

Square Hole |

Hex Hole |

Round Hole with Keyway |

Adjust machinery in tight spaces—the ratcheting action on these crank handles means you don’t have to turn them in complete circles. Flip the control switch to reverse the ratcheting direction. To reduce strain on your arm, these handles have a free-spinning grip. The through hole in the hub attaches anywhere along the length of unthreaded shafts. Handles are black powder-coated steel.

Steel—Steel handles are stronger than iron.

Round Hole with Keyway—Handles with a round hole have an ANSI standard keyway for mounting to keyed shafts.

Keyway | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Hub Projection | Hole Wd. | Hole Dia. | Wd. | Dp. | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Powder-Coated Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Hex Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K13 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K16 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K55 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K56 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1 1/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K48 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Round Hole with Keyway | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 1/2" | 1/8" | 1/16" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K14 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | — | 5/8" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K17 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 3/4" | 3/16" | 3/32" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K57 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | — | 1" | 1/4" | 1/8" | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K58 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Square Hole | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 3/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K11 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K12 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 7" | 4 9/32" | 19/32" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K15 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 1/2" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K51 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 5/8" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K52 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 10" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K53 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 3/4" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K42 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 12" | 4 9/16" | 7/8" | 1" | — | — | — | 3 11/16" | Phenolic | Black | Not Rated to 300° F | 6393K45 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Machinable-Hub-Mount Crank Handles

|

Mill specific holes or keyways in the hub to meet your specifications or weld in place. Often used on cross-slide tables, these crank handles provide leverage to maximize force for turning and tightening.

Stationary Grip—Handles with a stationary grip are best when you need to apply high force because the grip won’t rotate or slip.

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Dia. | Projection | Ht. | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1018 Low-Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 5/8" | 3 5/8" | 1" | 1 1/4" | 2 7/32" | Steel | 6040K42 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4" | 4 5/16" | 1 1/16" | 1 5/16" | 2 1/2" | Steel | 6040K44 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | 4 1/2" | 1 1/4" | 1 3/8" | 2 11/16" | Steel | 6040K45 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5 1/2" | 4 15/16" | 1 1/4" | 1 13/16" | 2 7/8" | Steel | 6040K46 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 6 1/2" | 5 1/8" | 1 1/4" | 1 15/16" | 2 15/16" | Steel | 6040K47 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8" | 5 7/16" | 1 3/8" | 2 1/16" | 2 7/8" | Steel | 6040K48 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 9" | 6 1/16" | 1 9/16" | 2 7/16" | 3 3/16" | Steel | 6040K49 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 11" | 7" | 1 3/4" | 3" | 3 1/2" | Steel | 6040K52 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Adjustable-Position Threaded-Hole-Mount Crank Handles

|  |

Handle with Revolving/Folding Grip Shown Folded |

Use these crank handles for applications that involve frequent machinery adjustments. They provide leverage to maximize force for turning and tightening. Made of plastic, these handles resist oil, grease, and solvents.

Folding Grip—Handles with a folding grip have a grip that folds out of the way when not in use.

Revolving Grip—Handles with a revolving grip let you turn continuously without having to adjust your grasp while also reducing strain on your arm.

Nylon—Nylon handles are a lightweight alternative to metal. They resist oil, grease, and solvents.

Thread | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Size | Dp. | Handle Lg. | Projection | Hub Projection | Ht. | Material | Color | Temperature Range | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 6129K1 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 6129K2 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 7/16" | 2 1/16" | 2 19/32" | Nylon | Black | 15° F to 245° F | 6129K3 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving/Folding Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Black Nylon | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5/16"-18 | 11/16" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 6129K4 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3/8"-16 | 21/32" | 3" | 3 5/8" | 1 3/4" | 2 7/32" | Nylon | Black | 15° F to 245° F | 6129K5 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1/2"-13 | 25/32" | 4 13/16" | 4 27/32" | 2 1/16" | 3" | Nylon | Black | 15° F to 245° F | 6129K6 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

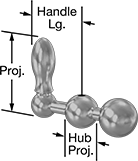

Balanced Machinable-Hub-Mount Crank Handles

|

Balanced weight distribution prevents unintentional handle movement, even in high-vibration applications. Mill specific holes or keyways in the hub to meet your specifications or weld in place. Often used on cross-slide tables, these crank handles provide leverage to maximize force for turning and tightening.

Stationary Grip—Handles with a stationary grip are best when you need to apply high force because the grip won’t rotate or slip.

Revolving Grip—Handles with a revolving grip let you turn continuously without having to adjust your grasp while also reducing strain on your arm.

Set Screw Starting Hole—Handles with a set screw starting hole have a starting hole in the hub that acts as a guide for drilling a larger hole.

Hub | Grip | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Handle Lg. | Projection | Dia. | Projection | Ht. | Material | Features | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Stationary Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 1/2" | 2 9/32" | 7/8" | 7/8" | 2 1/8" | Steel | 1/4" Diameter Set Screw Starting Hole | 6035K11 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 3/4" | 2 21/32" | 1" | 1" | 2 15/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 6035K12 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3" | 4 1/16" | 1 3/8" | 1 3/8" | 3 3/4" | Steel | 1/4" Diameter Set Screw Starting Hole | 6035K17 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Revolving Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

12L14 Carbon Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 1 23/32" | 2 15/16" | 1" | 1" | 2 23/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 6036K11 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 2 29/32" | 4 9/32" | 1 3/8" | 1 3/8" | 3 31/32" | Steel | 1/4" Diameter Set Screw Starting Hole | 6036K16 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||