Filter by

Wire Type

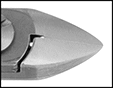

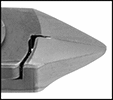

Cut Profile

Grip Style

For Cutting

Jaw Opening Style

Cutting Edge Location

Head Offset Angle

U.S.–Mexico–Canada Agreement (USMCA) Qualifying

REACH

DFARS Specialty Metals

Export Control Classification Number (ECCN)

RoHS

Surface Resistivity

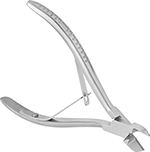

Wire Cutters with Carbide Blades

Jaw | For Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall Lg. | Cut Profile | Cutting Edge Location | Lg. | Opening Style | Max. Dia. | Max. Ga. | Type | Material | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Cushion Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | Pointed | Side | 3/8" | Spring Assisted | 0.040" | 18 | Soft, Hardened | Steel | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Ultra Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | Semi-Flush | Side | 9/16" | Spring Assisted | 0.047" | 17 | Soft, Hardened | Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Head and Ultra Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | Semi-Flush | Side | 9/16" | Spring Assisted | 0.032" | 20 | Soft, Hardened | Steel | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Corrosion-Resistant Wire Cutters with Carbide Blades

Jaw | For Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall Lg. | Cut Profile | Cutting Edge Location | Lg. | Opening Style | Max. Dia. | Max. Ga. | Type | Performance | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Plain Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | Semi-Flush | Side | 1/2" | Manual | 0.012" | 28 | Hardened | Corrosion Resistant | Stainless Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Static-Control Wire Cutters with Carbide Blades

Jaw | For Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall Lg. | Cut Profile | Cutting Edge Location | Head Offset Angle | Lg. | Opening Style | Max. Dia. | Max. Ga. | Type | Performance | Surface Resistivity | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Cushion Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | Flush | Side | — | 1/2" | Manual | 0.059" | 16 | Soft, Hardened | Static Control, Static Dissipative | 1× 10^9 ohm/sq. | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Ultra Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | Semi-Flush | Side | — | 7/16" | Spring Assisted | 0.040" | 18 | Soft, Hardened | Static Control, Static Dissipative | 1× 10^4Ω⋅cm to 1× 10^7Ω⋅cm | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Head and Cushion Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/4" | Pointed | Side | — | 1/2" | Spring Assisted | 0.057" | 15 | Soft, Hardened | Antistatic, Static Control | — | Steel | 000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | Flush | Side | — | 1/2" | Manual | 0.059" | 16 | Soft, Hardened | Static Control, Static Dissipative | 1× 10^9 ohm/sq. | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Tapered Head and Ultra Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 3/4" | Flush | Side | 29° | 7/16" | Spring Assisted | 0.040" | 18 | Soft, Hardened | Static Control, Static Dissipative | 1× 10^4Ω⋅cm to 1× 10^7Ω⋅cm | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 5" | Flush | Side | — | 7/16" | Spring Assisted | 0.040" | 18 | Soft, Hardened | Static Control, Static Dissipative | 1× 10^4Ω⋅cm to 1× 10^7Ω⋅cm | Steel | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Static-Control Optical Fiber Cutters with Carbide Blades

Jaw | For Wire | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Overall Lg. | Cut Profile | Cutting Edge Location | Lg. | Opening Style | Max. Dia. | Max. Ga. | Type | Performance | Material | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Oval Head and Cushion Grip | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 4 1/2" | Semi-Flush | Side | 1/2" | Spring Assisted | 9 μm 0.057" | __ 15 | Optical Fiber Soft, Hardened, Kevlar | Antistatic, Static Control | Steel | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||