About Sleeving

More

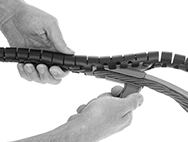

Slotted Spiral Sleeving

With a unique overlapping link structure, you can open and close this sleeving like a zipper using the included tool. The tool’s open design and the slots in the sleeving make it easy to branch off wires from your bundle as you’re zipping it shut. Thanks to its structure, this sleeving is better at resisting wear and tear than standard spiral sleeving. There are also no pinch points when it bends and flexes, so it’s great where there’s a lot of movement and vibration. Unlike cable ties and tape, it can be unwound and reused. Made of polypropylene, it resists chemicals and solvents.

As your setup changes, you can use the installation tool to add wire, cable, or hose to your sleeving without having to disassemble or move your equipment. That makes this sleeving ideal where frequent repair is necessary.

Note: The installation tool only works with slotted spiral sleeving, not other types of spiral sleeving.

| ID | Expanded ID | OD | Wall Thick. | Includes | Temperature Range, °F | Specifications Met | Color | Each | |

10 ft. | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Polypropylene Plastic | |||||||||

| 1/2" | 5/8" | 5/8" | 1/32" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

| 7/8" | 1 1/32" | 1" | 1/32" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 00000 |

100 ft. | |||||||||

Polypropylene Plastic | |||||||||

| 9/32" | 11/32" | 5/16" | 1/64" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

| 1/2" | 5/8" | 5/8" | 1/32" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

| 11/16" | 13/16" | 3/4" | 1/32" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

| 7/8" | 1 1/32" | 1" | 1/32" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

| 7/8" | 1 1/4" | 1 1/4" | 3/64" | Installation Tool | -75° to 230° | UL 94 HB | Black | 0000000 | 000000 |

Low-Profile Corrugated Sleeving

With a flat, oval shape, this sleeving fits better in confined spaces than standard corrugated sleeving. It’s great for mounting flush behind or below machinery and panels. Its corrugated construction resists wear, tear, and impact similar to conduit, but it’s more flexible. Made of polypropylene, this sleeving won’t break down when exposed to chemicals and solvents.

Orange sleeving is more visible than black sleeving. It’s commonly used to designate high-voltage wiring.

For technical drawings and 3-D models, click on a part number.

Inside | 4 ft. Lg. | ||||

|---|---|---|---|---|---|

| Lg. | Wd. | Wall Thick. | Temperature Range, °F | Each | |

Polypropylene Plastic | |||||

Black | |||||

| 1" | 13/32" | 1/64" | -40° to 255° | 0000000 | 000000 |

| 1 11/32" | 7/16" | 1/64" | -40° to 255° | 0000000 | 00000 |

| 2 1/8" | 9/16" | 1/64" | -40° to 255° | 0000000 | 00000 |

Orange | |||||

| 1" | 13/32" | 1/64" | -40° to 255° | 0000000 | 00000 |

| 1 11/32" | 7/16" | 1/64" | -40° to 255° | 0000000 | 00000 |

| 2 1/8" | 9/16" | 1/64" | -40° to 255° | 0000000 | 00000 |

Two-Piece Interlocking Corrugated Sleeving

The two halves of this sleeving nest into each other, fully enclosing contents. It has interlocking ridges that overlap to keep out dust and dirt, even when flexing. The corrugated construction gives it the impact and abrasion resistance of conduit, but with more flexibility.

Hinged Interlocking Corrugated Sleeving

A hinge along the entire length makes this one-piece sleeving easy to open for installation. Interlocking ridges overlap along the opening to protect contents from dirt and dust, even when flexing. Wrap it around wire, cable, and hose without disconnecting them. The corrugated construction offers the impact and abrasion resistance of conduit, but with more flexibility.