Filter by

For Wire Gauge

Insulation

Application

Splice Type

Maximum Temperature

Insulation Material

Minimum Wire Combination

Performance

DFARS Specialty Metals

Export Control Classification Number (ECCN)

Sold As

Quick-Connect Clamp-On Wire Connectors

Wire Connectors | DIN Rail Mounting Adapters | Covers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Style | No. of | Ga. | Construction | Insulation Color | Lever Color | Terminal Material | Max. Temp., ° F | Max. Voltage | No. of Test Sockets | Certification | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polycarbonate Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 2 | 24 to 12 | Solid, Stranded | Clear | Orange | Tin-Plated Copper | 185 | 600V AC 600V DC | 2 | UL Listed | 10 | 0000000 | 00000 | 10 | 0000000 | 000000 | 4 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 3 | 24 to 12 | Solid, Stranded | Clear | Orange | Tin-Plated Copper | 185 | 600V AC 600V DC | 2 | UL Listed | 10 | 0000000 | 0000 | 10 | 0000000 | 00000 | 4 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| A | 5 | 24 to 12 | Solid, Stranded | Clear | Orange | Tin-Plated Copper | 185 | 600V AC 600V DC | 2 | UL Listed | 10 | 0000000 | 00000 | 10 | 0000000 | 00000 | 4 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 3 | 28 to 12 | Solid, Stranded | Gray | Orange | Tin-Plated Copper | 185 | 600V AC 600V DC | 1 | UL Listed | 50 | 000000 | 00000 | 10 | 0000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| B | 5 | 28 to 12 | Solid, Stranded | Gray | Orange | Tin-Plated Copper | 185 | 600V AC 600V DC | 1 | UL Listed | 40 | 000000 | 00000 | 10 | 0000000 | 00000 | — | ——— | 0 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Gel Wire Splice Covers

Inside | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire Gauge | Lg. | Wd. | Ht. | Lg. | Wd. | Ht. | Color | Material | Max. Temp., ° F | Enclosure Rating | Flammability Rating | Pkg. Qty. | Pkg. | ||

| 30 to 10 | 1 1/16" | 25/32" | 23/32" | 1 5/8" | 1 1/8" | 3/4" | Orange | Plastic | 120 | IP08 | UL 94 HB | 4 | 0000000 | 000000 | |

| 30 to 10 | 1 7/32" | 1 1/32" | 3/4" | 1 3/4" | 1 7/16" | 15/16" | Gray | Plastic | 120 | IP08 | UL 94 HB | 2 | 0000000 | 0000 | |

| 30 to 10 | 1 9/16" | 1 3/32" | 3/4" | 2 1/16" | 1 1/2" | 15/16" | Yellow | Plastic | 120 | IP08 | UL 94 HB | 1 | 0000000 | 0000 | |

Crimp-On Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Insulation Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Certification | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 to 22 | Stranded | 0.9" | Yellow | Tin-Plated Copper | 220 | 300V AC 300V DC | CSA Certified, UL Listed | 5 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Noninsulated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 to 24 | Solid, Stranded | 0.47" | — | Tin-Plated Copper | 345 | 600V AC 600V DC | C-UL Listed, UL Listed | 100 | 0000000 | 0000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

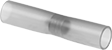

Heat-Shrink Crimp-On Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Insulation Color | Terminal Material | Max. Temp., ° F | Max. Voltage, V AC | Shrink Temp., ° F | Certification | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyolefin Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 26 to 22 | Solid, Stranded | 1.1" | Clear | Tin-Plated Copper | 220 | 600 | 275 | C-UL Listed, UL Listed | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Moisture-Resistant Insulation-Piercing Wire Connectors

Wire Connectors | Electrical Connector Pliers | Crimpers | |||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

For Wire | Wire Combination | Insulation | |||||||||||||||||||

Style | No. of | Ga. | Construction | Min. | Max. | Max. OD | Color | Material | Terminal Material | Filler Material | Max. Temp., ° F | Max. Voltage | Max. Current, mA | Pkg. Qty. | Pkg. | Each | Each | ||||

| A | — | 24 to 16 | Solid, Stranded | Four 24-Ga. Wires | Three 16-Ga. Wires | — | Blue | Polyolefin | Tin-Plated Bronze | Gel | 220 | 50V DC | 175 | 100 | 000000 | 000000 | ——— | 0 | 000000 | 00000 | |

| B | 2 | 26 to 22 | Solid | — | — | 0.06" | Yellow/Clear | Polycarbonate | Tin-Plated Copper | Gel | 285 | 30V AC | — | 25 | 0000000 | 00000 | 0000000 | 000000 | ——— | 0 | |

| B | 2, 3 | 26 to 19 | Solid | — | — | 0.06" | Red/Clear | Polycarbonate | Tin-Plated Copper | Gel | 285 | 30V AC | — | 25 | 0000000 | 0000 | 0000000 | 00000 | ——— | 0 | |

| B | 2, 3 | 26 to 19 | Solid | — | — | 0.08" | Red/Clear | Polypropylene | Tin-Plated Copper | Gel | 285 | 30V AC | — | 100 | 0000000 | 00000 | 0000000 | 00000 | ——— | 0 | |

| B | 2 | 26 to 19 | Solid | — | — | 0.08" | Yellow/Clear | Polypropylene | Tin-Plated Copper | Gel | 285 | 30V AC | — | 50 | 0000000 | 00000 | 0000000 | 00000 | ——— | 0 | |

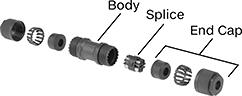

Watertight Set Screw Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | Ga. | Construction | Material | Lg. | Insulation Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Enclosure Rating | End Cap Construction | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Nylon Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 8 | 26 to 18 | Stranded | Aluminum, Copper | 2.83" | Black | Nickel-Plated Brass | 185 | 130V AC 130V DC | IP68 | Sealed | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

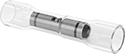

Tight-Hold Heat-Shrink Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Insulation Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Shrink Temp., ° F | Certification | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyolefin Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 to 22 | Solid, Stranded | 0.88" | Clear | — | 230 | 600V AC 600V DC | 275 | UL Recognized Component | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder and Crimp-On Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 24 to 22 | Solid, Stranded | 0.88" | Clear | Tin-Plated Copper | 220 | 600V AC 600V DC | 275 | — | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twist-On Butt Splices

Moisture-Resistant Insulation-Piercing Wire Taps

For Wire | For Tap Wire | Insulation | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Ga. | Construction | Wire Connection Position | Max. OD | Color | Material | Terminal Material | Filler Material | Max. Temp., ° F | Max. Voltage, V AC | Pkg. Qty. | Pkg. | ||

| 26 to 19 | Solid | 26 to 19 | Solid | Tap/Main | 0.08" | Blue/Clear | Polypropylene | Tin-Plated Copper | Gel | 285 | 30 | 50 | 0000000 | 000000 | |

Tight-Hold Heat-Shrink Reducing Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Insulation Color | Stripe Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Shrink Temp., ° F | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyolefin Insulation | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Solder and Crimp-On Connection | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 to 18 × 24 to 22 | Solid, Stranded | 1.5" | Red | Red × White | Tin-Plated Copper | 230 | 600V AC 600V DC | 275 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat-Shrink Reducing Crimp-On Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Insulation Color | Stripe Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Shrink Temp., ° F | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Plastic Insulation with Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 to 18 × 24 to 22 | Solid, Stranded | 1.47" | Clear | Red × White | Tin-Plated Copper | 255 | 600V AC 600V DC | 190 | 10 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyolefin Insulation with Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 to 18 × 24 to 22 | Solid, Stranded | 1.6" | Red | Red | Tin-Plated Copper | 220 | 600V AC 600V DC | 275 | 10 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Heat-Shrink 2-to-1 Wire Crimp-On Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

No. of | Ga. | Construction | Lg. | Insulation Color | Stripe Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Shrink Temp., ° F | Pkg. Qty. | Pkg. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Polyolefin Insulation with Window | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 3 | 24 to 22 | Stranded | 1.8" | Clear | Red × White | Tin-Plated Copper | 250 | 600V AC 600V DC | 250 | 10 | 0000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Twist-On Insulation-Piercing Wire Taps

For Wire | For Tap Wire | Insulation | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Ga. | Construction | Wire Connection Position | Color | Material | Terminal Material | Max. Temp., ° F | Max. Voltage | Pkg. Qty. | Pkg. | ||

| 26 to 24 | Stranded | 24 to 18 | Stranded | T-Tap | Black/Red | Nylon | Tin-Plated Brass | 245 | 600V AC 600V DC | 6 | 0000000 | 000000 | |

Insulation-Piercing Wire Connectors

Reducing Crimp-On Butt Splices

For Wire | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Ga. | Construction | Lg. | Stripe Color | Terminal Material | Max. Temp., ° F | Max. Voltage | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Noninsulated | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Single Crimp | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 22 to 18 × 26 to 24 | Solid, Stranded | 0.7" | Red × White | Tin-Plated Copper | 345 | 600V AC 600V DC | 25 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||