Filter by

System of Measurement

Diameter

Shape

Flexibility

Specifications Met

Military Specification

Performance

Maximum Temperature

Appearance

Finish

Export Control Classification Number (ECCN)

DFARS Specialty Metals

Tolerance Rating

Profile

Hardness

Minimum Temperature

Fabrication

About Stainless Steel

Compare over 25 types of stainless steel to find the right material for you—all with material certificates for traceability.

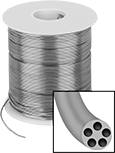

Bend-and-Stay Stainless Steel Wire

Round Profile

Container | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Dia. | Dia. Tolerance | Lg., ft. | Type | Net Wt., lb. | Fabrication | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 1 | Package | — | Cold Drawn | ASTM A580 | 50 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 410 | Spool | 1/4 | Cold Drawn | ASTM A580 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 1,655 | Spool | 1 | Cold Drawn | ASTM A580 | 1 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 8,275 | Spool | 5 | Cold Drawn | ASTM A580 | 1 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316/316L Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 1 | Package | — | Cold Drawn | ASTM A580 | 25 | 000000000 | 0000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 30 | Coil | — | Cold Drawn | ASTM A580 | 1 | 000000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 410 | Coil | 1/4 | Cold Drawn | ASTM A580 | 1 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 1,655 | Coil | 1 | Cold Drawn | ASTM A580 | 1 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

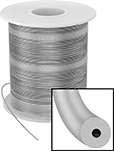

Spring-Back Stainless Steel Wire

Coil

Dia. | Dia. Tolerance | Lg. | Container Net Wt., lb. | Fabrication | Specs. Met | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0004" to 0.0004" | 410 ft. | 1/4 | Cold Drawn | ASTM A313, ASTM A555 | 00000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0004" to 0.0004" | 1,655 ft. | 1 | Cold Drawn | ASTM A313, ASTM A555 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

PTFE-Coated 304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 68" | — | — | ASTM A313 | 0000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

316 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 410 ft. | 1/4 | Cold Drawn | ASTM A313 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.001" to 0.001" | 1,655 ft. | 1 | Cold Drawn | ASTM A313 | 00000000 | 00000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Package

Dia. | Dia. Tolerance | Lg., ft. | Fabrication | Specs. Met | Pkg. Qty. | Pkg. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

304 Stainless Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| 0.015" | -0.0005" to 0.0005" | 1 | Cold Drawn | ASTM A313, ASTM A555 | 100 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Super-Elastic Nitinol Wire

Packages

2 ft. Long | |||||||||

|---|---|---|---|---|---|---|---|---|---|

Dia. | Dia. Tolerance | Finish | Temper Rating | Tensile Strength, psi | Specs. Met | Pkg. Qty. | Pkg. | ||

| 0.015" | -0.0004" to 0.0004" | Black Oxide | Spring | 181,000 | ASTM F2063 | 5 | 0000000 | 000000 | |

Ultra-High-Temperature Tantalum Wire

Rosin Flux-Core Solder for Electronics and Electrical Applications

Leaded, Flux Core

Lead-Free, Flux Core

Material Composition | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Silver | Antimony | Copper | Lead | Melting Temp., ° F | Dia. | Wt., lb. | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Brass, Bronze, Copper, Nickel, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | — | 0.5% | 0% | 460 | 0.015" | 1 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn97Cu2Sb0.8Ag0.2 | 97% | 0.2% | 0.8% | 2% | 0% | 460 | 0.015" | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn97Cu3 | 97% | — | — | 3% | 0% | 480 | 0.015" | 1 | 00000000 | 00000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn99.3Cu0.7 | 99.3% | — | — | 0.7% | 0% | 440 | 0.015" | 1 | 00000000 | 000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

No-Clean Flux-Core Solder for Electronics and Electrical Applications

|

Lead-Free, Flux Core

Material Composition | 1 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Silver | Copper | Lead | Dia. | Melting Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Brass, Bronze, Copper, Nickel, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 0.015" | 425 | 0000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Flow No-Clean Flux-Core Solder for Electronics and Electrical Applications

Lead-Free, Flux Core

Material Composition | 1 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Silver | Antimony | Copper | Lead | Dia. | Melting Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Brass, Bronze, Copper, Nickel, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0% | 0.5% | 0% | 0.015" | 425 | 0000000 | 0000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Quick-Flow Rosin Flux-Core Solder for Electronics and Electrical Applications

Acid Flux-Core Solder for Electronics and Electrical Applications

|

Lead-Free, Flux Core

Material Composition | 1 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Silver | Copper | Lead | Dia. | Melting Temp., ° F | Each | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Brass, Bronze, Copper, Nickel, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn96.5Ag3Cu0.5 | 96.5% | 3% | 0.5% | 0% | 0.015" | 460 | 00000000 | 0000000 | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Easy-Clean Flux-Core Solder for Electronics and Electrical Applications

Solder for Electronics and Electrical Applications

|

Lead-Free, Flux Required

Material Composition | 1 lb. | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

Solder Alloy | Tin | Copper | Lead | Dia. | Melting Temp., ° F | Each | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

For Joining Brass, Bronze, Copper, Nickel, Stainless Steel, and Steel | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Sn99.3Cu0.7 | 99.3% | 0.7% | 0% | 0.015" | 440 | 0000000 | 000000 | ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||