View a wire gauge conversion chart.

Spring-Back Multipurpose 304 Stainless Steel Wire

This wire bounces back after bending. Often used to construct springs and wire rope, 304 stainless steel is a good all-around choice for a wide range of applications.

PTFE-coated wire has a slippery surface, so it’s especially useful as a fish wire when navigating through confined spaces.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

- Heat Treatment: Hardened

- Tensile Strength: 205,000 psi

- Specifications Met: ASTM A313, ASTM A555

1 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Fabrication | Max. Temperature, °F | Pkg. Qty. | Pkg. | |

Mirror-Like | ||||||

| 0.024" | -0.0005" to 0.0005" | Cold Drawn | 570° | 100 | 0000000 | 000000 |

- Heat Treatment: Hardened

- Tensile Strength: Not Rated

- Specifications Met: ASTM A313

68" Lg. | |||||

|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Finish Color | Max. Temperature, °F | Each | |

| 0.024" | -0.0005" to 0.0005" | Gray | 500° | 0000000 | 000000 |

Lubricated 1080 Spring Steel Wire

- Heat Treatment: Hardened

- Tensile Strength: 261,000 psi

- Specifications Met: ASTM A228

Also known as music wire. This wire is coated with phosphate for corrosion resistance and lubricity. Use it for bundling and as tag wire. It will spring back after bending.

1 ft. Lg. | ||||||

|---|---|---|---|---|---|---|

| Dia. | Dia. Tolerance | Heat Treatment | Temperature Range | Pkg. Qty. | Pkg. | |

| 0.024" | -0.0005" to 0.0005" | Hardened | Not Rated | 100 | 0000000 | 00000 |

Hardened Undersized High-Speed M2 Tool Steel Rods

- Yield Strength: See table

- Hardness: Rockwell C60 (Very Hard)

These rods, also known as drill blanks, have an undersized diameter for machining your own drill bits. They're hardened for increased abrasion and impact resistance. M2 tool steel offers a nice balance of wear resistance and machinability. It has a high molybdenum content, which allows it to maintain sharp cutting edges even at elevated temperatures.

| Dia. | Dia. Tolerance | Drill Bit Size | Lg. | Yield Strength | Mechanical Finish | Straightness Tolerance | Each | |

| 0.024" | -0.0002" to 0" | 73 | 1 1/8" | Not Rated | Precision Ground | 0.012" per ft. | 00000000 | 00000 |

Hardened Oversized High-Speed M2 Tool Steel Rods

- Yield Strength: Not Rated

- Hardness: Rockwell C60 (Very Hard)

Also known as reamer blanks, these rods have an oversized diameter that allows for finishing to your exact requirements. They're hardened for increased abrasion and impact resistance. M2 tool steel offers a nice balance of wear resistance and machinability. It has a high molybdenum content, which allows it to maintain sharp cutting edges even at elevated temperatures.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

| Dia. | Dia. Tolerance | Reamer Size | Lg. | Lg. Tolerance | Mechanical Finish | Straightness Tolerance | Each | |

| 0.024" | 0" to 0.0002" | 73 | 1 1/8" | -1/32" to 1/32" | Precision Ground | 0.012" per ft. | 00000000 | 00000 |

Ultra High-Temperature Molybdenum Wire

- Hardness: Rockwell C59 (Very Hard)

Able to handle high melting points and conduct heat and electricity, this 99.95% pure molybdenum wire is often used in lights to create a support for filaments. It resists oxidation and won’t corrode. Molybdenum is better at conducting heat and electricity than tantalum and platinum, which also have high melting points. It is not, however, as corrosion resistant.

![]() Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

Certificates with a traceable lot number are available for these products. Download certificates from ORDER HISTORY after your order ships.

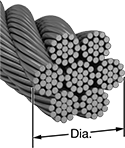

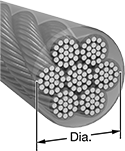

Difficult-to-Bend Corrosion-Resistant

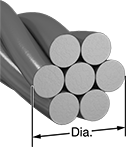

Small-Diameter Braided Wire—Not for Lifting

This braided wire has a stiff construction for use as bracing and guy wires. This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down. Individual wire strands are preformed to maintain their shape and prevent rope from unraveling when cut.

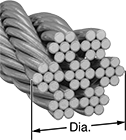

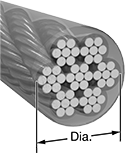

Extra-Flexible Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys. This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down.

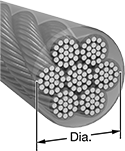

Corrosion-Resistant Small-Diameter Braided Wire—Not for Lifting

This stainless steel braided wire can handle corrosive environments, such as areas that are frequently washed down. This wire rope provides a good balance of abrasion resistance and flexibility.

Strand core is more crush resistant than hollow core.

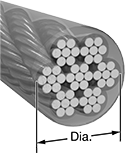

Extra-Flexible Coated Small-Diameter Braided Wire—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys. The nylon coating protects the wire from abrasion. Made of 18-8 stainless steel, this wire rope has good corrosion resistance.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

Chemical-Resistant Coated Small-Diameter Braided Wire—Not for Lifting

For use in the most demanding environments, the FEP (fluorinated ethylene propylene) coating on this braided wire has excellent chemical and weather resistance. Made of 18-8 stainless steel, this wire rope has good corrosion resistance. This wire rope provides a good balance of abrasion resistance and flexibility.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

Extra-Flexible Low-Stretch Coated Small-Diameter Braided Wire—Not for Lifting

More wires per strand than other wire rope provides the flexibility required for repeat bending over drums and pulleys. For use in precision mechanical applications, this rope is stretched during fabrication to minimize elongation under load. The nylon coating protects the wire from abrasion. Made of 18-8 stainless steel, this wire rope has good corrosion resistance.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.

Low-Stretch Coated Small-Diameter Braided Wire—Not for Lifting

For use in precision mechanical applications, this rope is stretched during fabrication to minimize elongation under load. The nylon coating protects the wire from abrasion. Made of 18-8 stainless steel, this wire rope has good corrosion resistance. This wire rope provides a good balance of abrasion resistance and flexibility.

Note: When attaching fittings to coated wire rope, the coating must be removed from the installation area.