Filter by

Diameter

Length

Thread Size

System of Measurement

Flexibility

For Use With

Drill Bit Size

Width

Application

Thickness

Tolerance Rating

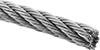

Wire Rope Core Type

Height

Thread Location

DFARS Specialty Metals

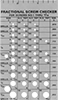

Measuring and Inspecting

Material Handling

Raw Materials

Fastening and Joining